What is Shop Weld?

Shop welds refer to welds that are performed in a controlled workshop environment, typically away from the actual construction site.

Shop Weld are opposed to being conducted on-site or in the field. Shop welding typically takes place in a dedicated welding shop or fabrication facility where the necessary equipment, tools, and resources are readily available.

Shop Weld Symbol

A shop weld symbol is a graphical representation used in welding to communicate specific information about the weld joint and welding process.

It provides a standardized way to convey the necessary details for a welder to understand and perform the welding operation accurately.

All welds carried out in the main fabrication shop, are represented by a shop welding symbol. For example, fillet weld, groove weld or any other type. Hence, there is no specific shop weld symbol, but it is common term for all welds made in a shop.

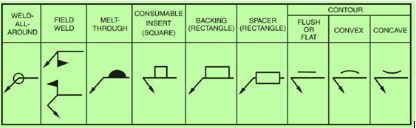

Following are the commonly used basic shop welding symbols.

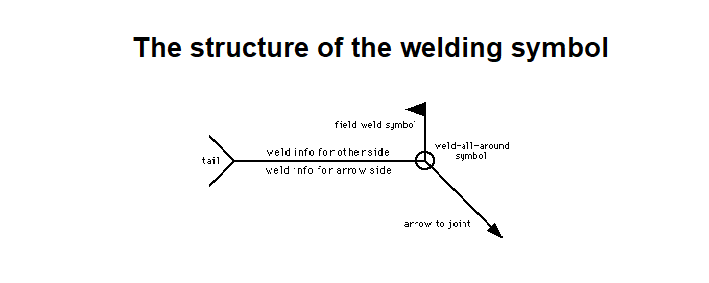

Elements of Shop Weld Symbol

The shop weld symbol consists of various elements that convey different aspects of the weld. Here are the main components typically included in a shop weld symbol:

- Reference Line: The reference line is a horizontal line that represents the joint to be welded. It serves as the starting point for other symbols and annotations.

- Arrow: The arrow is attached to the reference line and points to the location where the weld is to be applied.

- Welding Symbol: The welding symbol is a graphical representation that indicates the type of weld to be used. It can vary depending on the welding process, such as fillet weld, groove weld, plug weld, or spot weld.

- Dimensions: Dimensions are numerical values placed next to the welding symbol, indicating the size, length, or other measurements related to the weld. They provide essential information for the welder to understand the specific requirements of the weld.

- Supplementary Symbols: Supplementary symbols may be added to the shop weld symbol to provide additional information about the weld. These symbols can indicate details such as the weld contour, finishing requirements, backing or backing strip, and other specific instructions.

- Tail: A tail is an optional element that extends from the reference line or arrow. It may contain additional information or specifications related to the weld, such as the welding process, electrode type, or any special instructions.

Remember, Shop weld symbol is different from Field weld symbol, which is used for site welding.

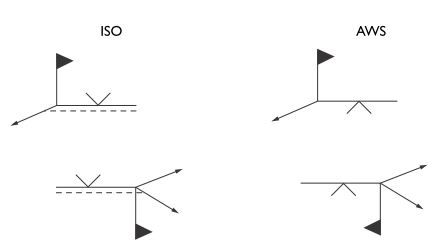

Following are the supplementary shop welding symbols:

Commonly used shop welding symbols

There are several commonly used shop welding symbols that represent different types of welds and welding operations.

Here are some of the most frequently encountered symbols:

- Fillet Weld Symbol: This symbol represents a fillet weld, which is a triangular weld that joins two surfaces at right angles. It is often depicted as a right triangle placed on the reference line, with the size of the weld specified on the legs of the triangle.

- Groove Weld Symbol: The groove weld symbol is used to represent a weld made in a groove or channel between two pieces of metal. It consists of a square or rectangular shape on the reference line, with details about the groove dimensions and weld preparation specified within or next to the symbol.

- Plug or Slot Weld Symbol: Plug or slot weld symbols indicate welds made in holes or slots in one piece of metal, joining it to another.

- Seam Weld Symbol: Seam weld symbols depict a continuous weld made along the length of a joint.

- Spot Weld Symbol: The spot weld symbol represents a series of circular welds made by applying pressure and heat at specific points. It is depicted by a circle placed on the reference line, with the number and spacing of the welds specified within or next to the symbol.

- Backing or Backing Strip Symbol: This symbol is used to indicate the use of a backing or backing strip in a weld joint.