Welding is important for joining metals in different industries, and engineers use symbols to tell welders what to do. One of these symbols is the seam welding symbol, which tells welders to join two metals together along a continuous line. In this blog, we will explain what the seam welding symbol is, how it works, and how to use it in engineering drawings and blueprints.

What is seam welding?

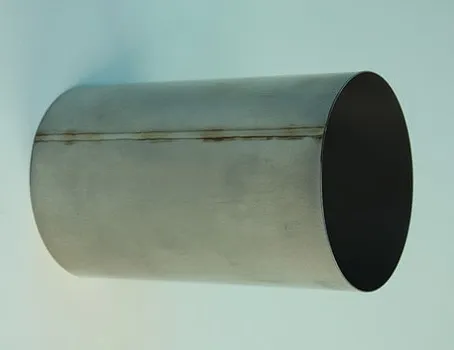

Seam welding is a fusion welding process that uses heat and pressure to join two or more workpieces along a continuous joint. It’s a variation of spot welding, where instead of creating individual weld spots, the welds overlap to create a leak-proof seam.

This type of welding is commonly used in applications that require a long, continuous weld and is particularly effective for sealing containers or tanks.

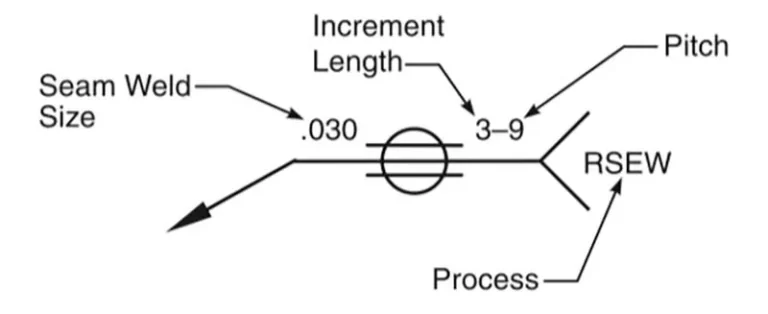

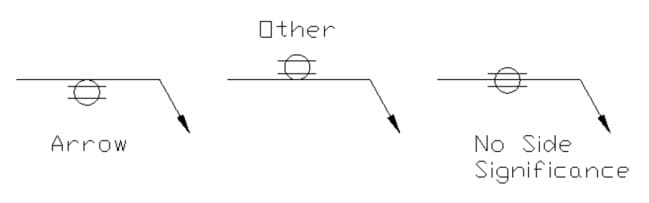

Resistance seam weld symbols

Resistance seam weld symbols do not possess inherent arrow or other side significance. However, supplementary symbols used in conjunction with them may have such significance. It is important to note that resistance seam weld symbols should be centered on the reference line to ensure accurate representation.

Dimensions of Resistance Seam Welds

The dimensions of resistance seam welds can be displayed on either side of the reference line. This flexibility allows for dimension placement based on the specific requirements of the welding drawing.

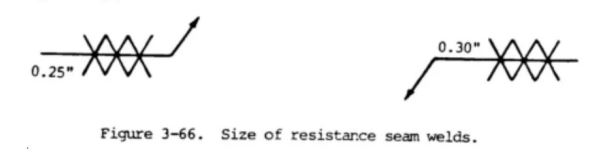

Size of Resistance Seam Welds

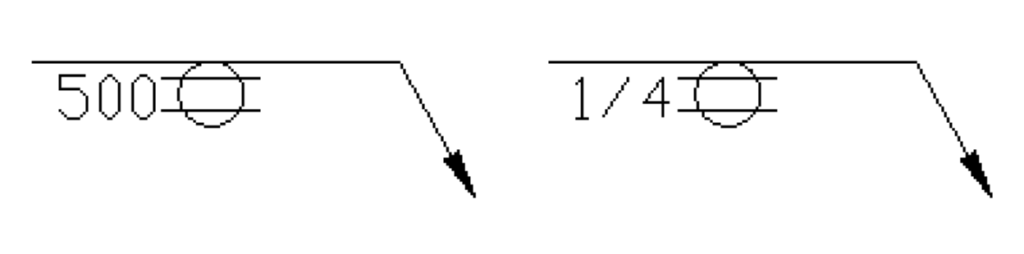

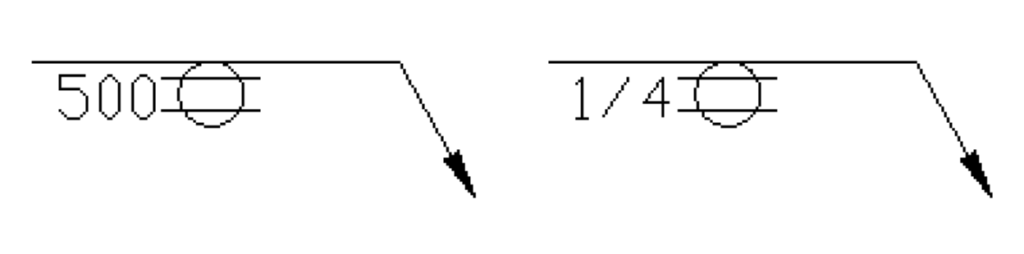

When dimensioning resistance seam welds, the size can be indicated using either size or strength measurements. Here are the guidelines for designating the size of resistance seam welds:

Size Designation: The size of resistance seam welds should be specified as the width of the weld. This width can be expressed either in fractions or in decimals, specifically in hundredths of an inch. The size designation can be shown to the left of the weld symbol.

Inch Marks: When indicating the size of the resistance seam weld, inch marks can be included or omitted as per the drawing conventions or specifications. The presence or absence of inch marks should be consistent throughout the drawing.

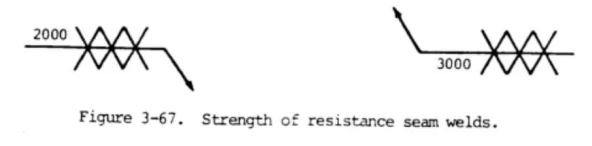

Strength of Resistance Seam Welds

In addition to size, the strength of resistance seam welds is also an important consideration. Here are the guidelines for designating the strength of resistance seam welds:

- Strength Designation: The strength of resistance seam welds should be specified as the minimum acceptable shear strength. This strength value is typically expressed in pounds per linear inch.

- Placement of Strength Designation: To indicate the strength of the resistance seam weld, the value should be shown to the left of the weld symbol. This placement ensures clear association with the weld and facilitates accurate understanding of the required strength.

AWS Seam Welding Symbol

Seam welding employs a process akin to spot welding, but it is carried out in an extended manner. Unlike plug or slot welding, it doesn’t necessitate any preliminary steps. The weld penetrates the top surface and fuses with the other component via heat application. The emblem for seam welding resembles that of spot welding, though it includes two parallel lines.

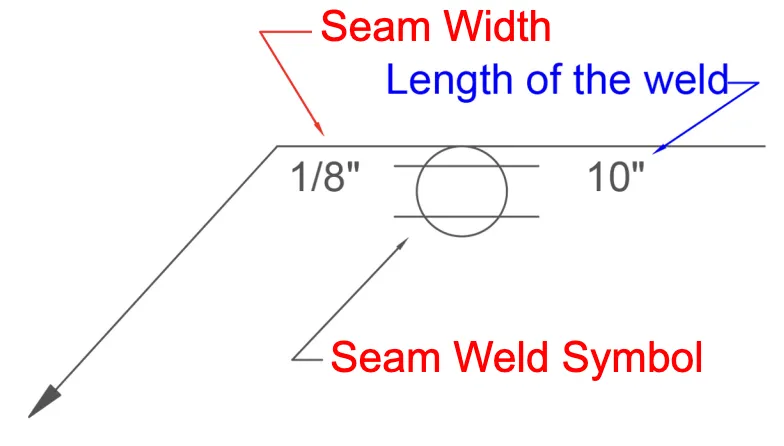

Typically, a seam weld’s welding symbol will be accompanied by a size or shear strength figure. This number is usually placed to the left of the welding symbol. The size represents the width of the welding bead. Shear strength, similar to that in spot welding, indicates the minimum amount of pound-force the weld can withstand per one inch of weld.

Length of Seam weld if required is given on the right side of the seam weld symbol. The length of the intended weld can be denoted by a figure placed on the right side of the symbol. This value conveys the desired length of the weld.

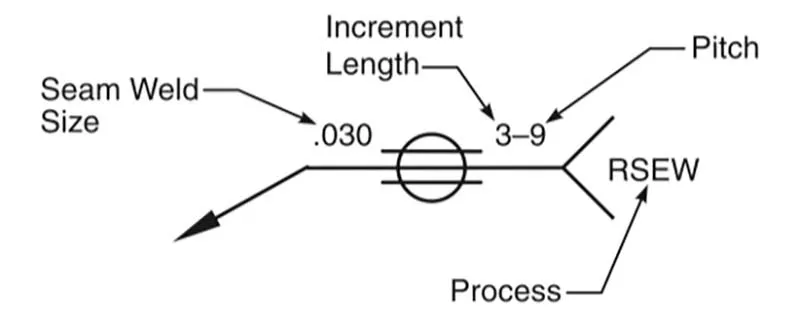

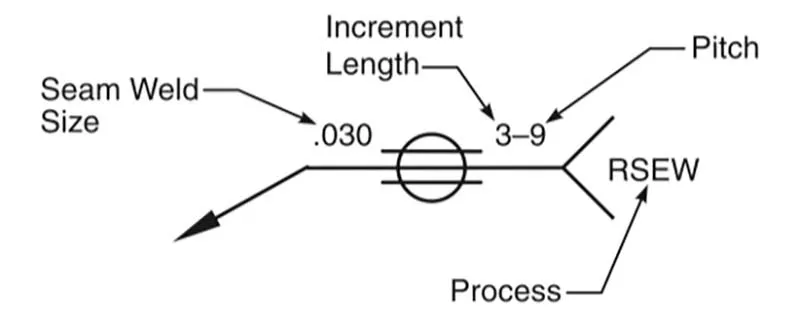

If weld is to be made intermittent, a Pitch size is denoted after the weld length as shown in the below seam welding symbol example.

Length of Resistance Seam Welds

- Length Indication: When the length of a resistance seam weld is specified on the welding symbol, it should be shown to the right of the welding symbol. This placement ensures clear association with the weld symbol and provides information about the desired length of the weld.

- Full Length Welding: If the resistance seam welding extends for the full distance between abrupt changes in the direction of the welding, there is no need to indicate a length dimension on the welding symbol. This indicates that the welding should cover the entire length without interruption.

- Partial Length Welding: In cases where the resistance seam welding extends for less than the distance between abrupt changes in the direction of the welding or less than the full length of the joint, the extent of the weld must be dimensioned. This dimensioning provides specific information about the partial length of the weld.

Pitch of Resistance Seam Welds

The pitch of intermittent resistance seam welding, which is the distance between the centers of the weld increments, should be designated and shown to the right of the length dimension .

This dimensioning provides information about the spacing between the individual weld increments in intermittent welding.

Termination of Intermittent Resistance Seam Welding

When intermittent resistance seam welding is used alone, the symbol indicates that the increments are located at the ends of the dimensioned length.

However, when it is used in combination with continuous resistance seam welding, the symbol indicates that spaces equal to the pitch minus the length of one increment are left at the ends of the dimensional length.

It is important to use separate symbols for intermittent and continuous resistance seam welding when the two types are combined to avoid confusion.

Seam Welding Procedure

Here’s a basic overview of the seam welding process:

- Preparation: As with any welding process, the surfaces of the materials to be welded should be clean. This means removing any paint, rust, or other contaminants that could interfere with the welding process.

- Placement: The two workpieces are placed between the rotating electrode wheels of the seam welding machine. The wheels are typically made of copper, which conducts heat very efficiently.

- Welding: The welding machine applies both heat and pressure to the workpieces. The heat is generated by electrical resistance as current passes through the workpieces, and the pressure is applied by the electrode wheels. The wheels move along the joint, creating a series of overlapping spot welds that form a continuous, leak-proof seam.

- Cooling: After the seam is created, it needs to be cooled. In some seam welding machines, the electrode wheels are water-cooled to help manage the heat produced during the welding process.