The world of welding is filled with a variety of specialized terms and symbols, each with its own unique meaning and significance. One such symbol, which is the focus of our discussion today, is the scarf groove weld symbol. This symbol is quite useful in depicting the type of weld needed for a particular job, and understanding it can prove to be of immense value for both novice and experienced welders.

What is a Scarf Groove Weld?

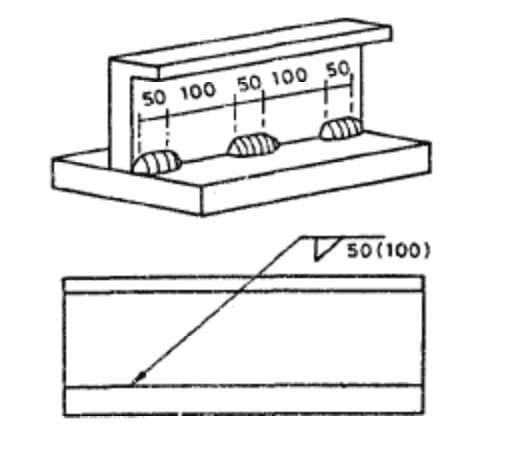

Before diving into the symbol, it’s essential to understand what a scarf weld is. A scarf weld is a type of groove weld that is often used when welding together two parts that need to be joined end-to-end usually by Forge Welding as shown in below figure.

A scarf joint, also referred to as a scarph joint, is a technique used to connect two pieces of material together by welding them end to end. This type of joint is employed when the required length of the material is not readily available. It serves as an alternative to other types of joints like the butt joint and the splice joint, and is often preferred in joinery due to its ability to produce a nearly invisible glue line..

The Scarf Groove Weld Symbol

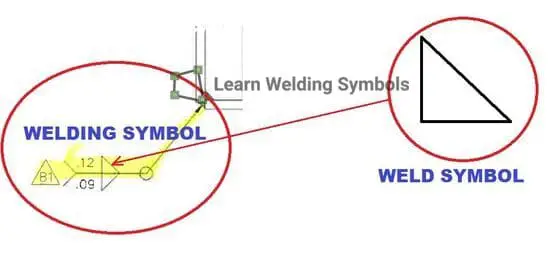

A welding symbol provides a convenient way to communicate between the design engineers and the welders. It’s a shorthand, a graphical representation that tells you what type of weld is required, where it’s needed, and how it should be done.

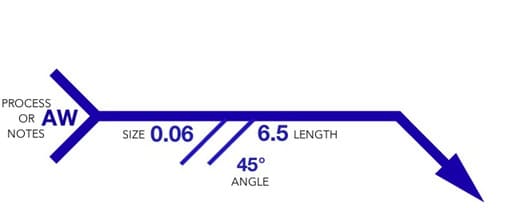

The scarf groove weld symbol, like all welding symbols, is made up of several parts:

- Reference Line: This is the horizontal line that serves as the foundation of the welding symbol. All other elements of the symbol are positioned in relation to this line.

- Arrow: This points to the location on the drawing where the weld is to be made.

- Tail: This is optional and is used when additional information needs to be included, such as the welding process, specifications, or other instructions.

- Basic Weld Symbols: These indicate the type of weld. For a scarf weld, it’s typically a two parallel taper lines placed on the reference line, representing the scarf-groove formed by the scarfing process.

- Dimensions and Other Data: These are figures and other information placed on the reference line, providing additional details such as the angle of the groove, size, and length of welding.

Reading the Scarf Groove Weld Symbol

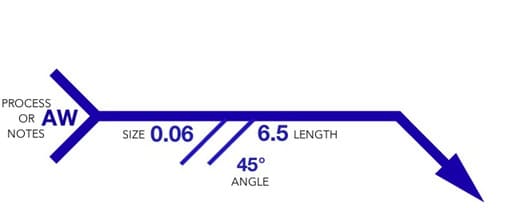

To read a scarf groove weld symbol, you start from the left, moving towards the right. On the left side of scarf weld symbol on the reference line, you’ll see the weld size.

Next, you look at the arrow, which will point to the exact location on the drawing where the weld needs to be made. If there’s a tail (which isn’t always necessary), you’ll check that for any special instructions.

Finally, you’ll look at the dimensions and other data. This will tell you the specifics of how the weld needs to be carried out. For example, in above symbol you see “45°”, this would mean the taper angle is 45 degrees. “0.06”, this indicates the width of the groove, while “6.5” would indicate the length of the weld.

Which Welding Process uses Scarf Weld Joint?

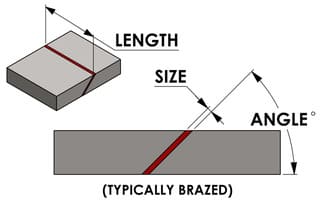

The scarf weld joint is commonly used in forge welding, soldering, and brazing processes.

Forge welding: Forge welding is a traditional method of joining metal pieces by heating them in a forge and then hammering or pressing them together. The scarf weld joint is often used in forge welding to create a strong and secure bond between the metal pieces.

Soldering: Soldering is a process that uses a lower melting point filler metal, called solder, to join two metal pieces together. The scarf weld joint can be used in soldering to ensure a strong and reliable connection between the pieces being joined.

Brazing: Brazing is a process similar to soldering, but it uses a higher melting point filler metal, called brazing alloy, to join metal pieces together. The scarf weld joint is commonly used in brazing to create a durable and leak-proof joint between the metal pieces.

How Scarf Welding Works?

To prepare the ends for joining, they are carefully shaped through a process called “upsetting.” Afterward, the ends are heated until they reach a yellow/white heat and then coated with flux (borax is typically used for mild steel). The heated ends are placed on the anvil’s surface.

The hammering process begins at the center of the joint, effectively removing any impurities or slag from the joint. Once the joint is formed, the Blacksmith focuses on shaping and refining it to ensure accuracy and smoothness.

Conclusion

The scarf groove weld symbol, like other welding symbols, is a crucial tool for ensuring clear, concise communication in the welding industry. Understanding this symbol and how to read it can greatly enhance a welder’s efficiency and the quality of their work. As with any skill, mastery comes with practice, so don’t be discouraged if you don’t get it right away. Keep studying, keep practicing, and soon it’ll become second nature.