What is TIG Welding?

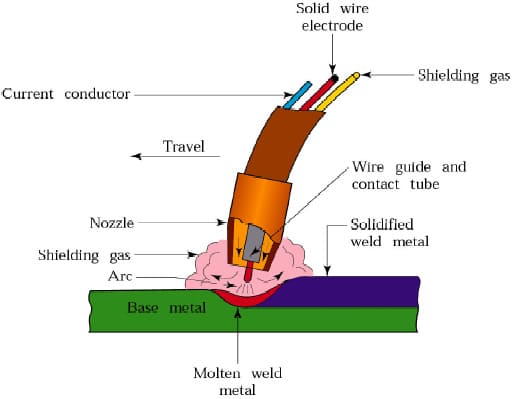

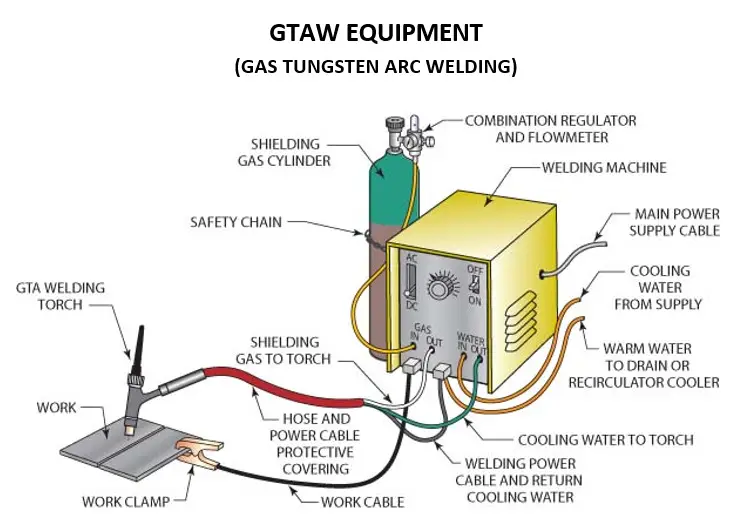

TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), is a precise and versatile welding process that uses a non-consumable tungsten electrode to create the weld.

Unlike other welding techniques, TIG welding requires the use of a shielding gas, typically argon or helium, to protect the weld area from atmospheric contamination. This results in high-quality, clean welds with excellent control over heat input and minimal spatter.

What are the Characteristics of TIG Welding?

✨ – One of the key characteristics of TIG welding is its ability to produce intricate and aesthetically pleasing welds, making it ideal for applications in industries such as aerospace, automotive, and artistic metalwork.

✨ – Unlike other forms of welding, TIG welding allows for greater control over the heat input and filler material deposition, resulting in minimal distortion and superior weld quality.

✨ – Furthermore, the use of a non-consumable tungsten electrode provides excellent arc stability while the shielding gas protects the molten weld puddle from contamination. This results in clean and smooth welds with minimal spatter or fumes.

✨ – Additionally, TIG welding can be used on a wide range of materials including stainless steel, aluminum, copper alloys, titanium, and more. Its precision and control make it particularly well-suited for thin materials while producing strong welds with consistent aesthetics.

What Kind of Electrodes are Used in TIG Welding?

Unlike other types of welding, TIG welding uses non-consumable tungsten electrodes that do not melt during the welding process.

These electrodes come in various compositions and sizes to suit different applications and materials.

⭐️ One popular type of electrode used in TIG welding is the thoriated tungsten electrode. It contains small amounts of thorium oxide, which enhances the electron emission and improves arc stability.

🛑🛑 However, due to health concerns associated with thorium exposure, there has been a shift towards using alternative formulations such as ceriated or lanthanated tungsten electrodes. 🛑🛑

Another important consideration is the diameter of the electrode, which impacts the heat input and penetration levels during TIG welding. Smaller diameter electrodes are suitable for thinner materials and precision work, while larger diameters are ideal for thicker sections requiring higher heat input.

Is it safe to use TIG welding without gas?

👇👇Using TIG welding without gas, also known as “gasless TIG welding,” is 👎🏻 not recommended👎🏻. TIG welding typically requires a shielding gas, such as argon, to protect the weld from contamination and oxidation.

Without the shielding gas, the weld quality may be compromised, leading to potential defects and weaker welds. It’s important to follow proper welding procedures and use the necessary equipment to ensure safety and quality in welding processes.

Can TIG Welding be Performed Without Gas?

Safe? 👨🏻🏭👨🏻🏭👨🏻🏭

Unless you are welding in a glovebox that is full of argon, and in that case it is perfectly fine to remove the cup and not use shielding gas in the torch (you still need argon flowing through the glove box), it won’t work without shielding gas (argon or helium) the tungsten will just burn up and the weld will be exposed to air.

If you actually managed to make a weld it would not be sound and will have no strength. 👇👇👇👇

Now if you are asking are you going to get hurt for example if you forget to turn the gas on and strike an arc?

👨🏻🏭The answer is NO👨🏻🏭 we’ve all done it before and other then realizing your mistake immediately as the sound is horrendous and having to regrind the tungsten and clean up the mess I’ve can’t imagine how you could manage to hurt yourself.

The torch is a different story the consumables could get destroyed if you kept welding without gas as the tungsten is burning and the spatter will eventually clog everything up. I suppose if you kept welding without the shielding gas the torch itself could be destroyed.

How to Decide if TIG Welding Without Gas is Worth It?

“Many welders often find themselves questioning whether TIG welding without gas is a worthwhile endeavor. “

The decision to forego traditional shielding gas can be influenced by factors such as cost, convenience, and accessibility of resources. For hobbyists or DIY enthusiasts on a budget, the option of using flux-cored TIG wire instead of gas can offer significant savings on consumables in the long run.

✨- However, it’s crucial to consider the potential trade-offs in weld quality and overall productivity when opting for this approach.

✨- In some cases, TIG welding without gas may be justified for certain applications where portability and outdoor use are critical. Flux-cored TIG wire offers improved resistance to atmospheric contamination compared to standard solid wires, making it a viable choice for on-site repairs or field work.

✨- Additionally, the absence of bulky cylinders and hoses makes this method more maneuverable in tight spaces, providing increased flexibility for welding in challenging environments.

Still, You have Option to do, here is how?

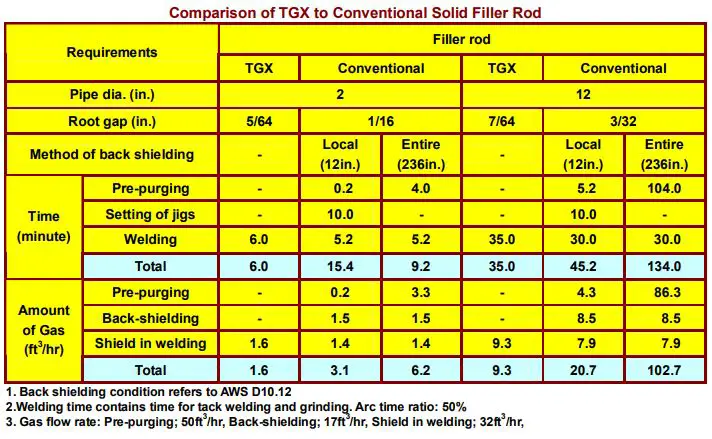

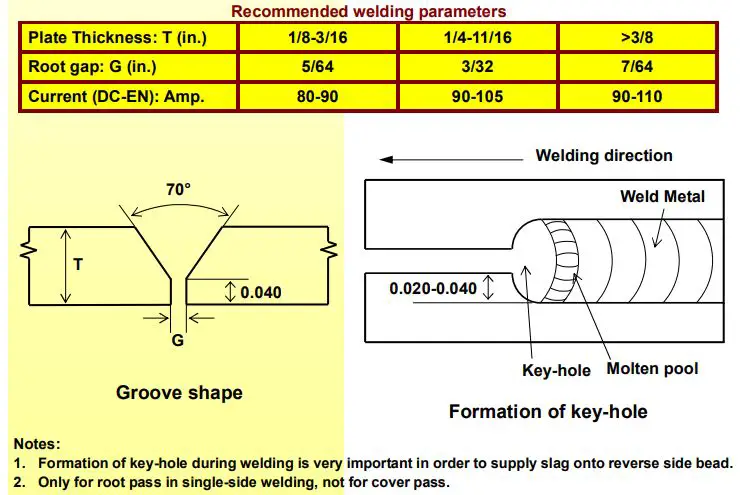

TGX are stainless steel flux-cored rods for TIG welding without back shielding.

Used for root pass to produce slag that protects reverse side bead from oxidation by the atmosphere. Using TGX flux-cored filler rods eliminates gas purging procedures.

TGX Series Flux Cored Filler Rods for TIG welding, produce slag to protect the

reverse side of the root pass from oxidation by the atmosphere.

Features

- No purging required on single sided root runs

- Saves time and money

- Easy to use

Applications

- Petrochemical plants

- Power stations

- Stainless steel pipe spools

Gasless TIG Welding Techniques

TIG Welding Polarity

TIG welding polarity plays a pivotal role in the quality of welds and overall welding process. The choice between DCEN (Direct Current Electrode Negative) and DCEP (Direct Current Electrode Positive) can significantly impact the penetration, bead shape, and overall strength of the weld.

While DCEN is typically used for welding thinner materials due to its deeper penetration and cleaner weld pool, DCEP offers better control over the weld puddle and is ideal for welding thicker materials.

Furthermore, understanding the effects of each polarity on different metals can elevate the welding process to new levels. For instance, using DCEN for aluminum TIG welding can result in improved cleaning action and reduced tungsten contamination, leading to superior quality welds.

On the other hand, utilizing DCEP for stainless steel welding can provide better heat control and a more stable arc.

TGX welding meaning

TGX welding, also known as flux cored wire TIG welding, has revolutionized the industry with its gasless capabilities. By utilizing a flux core within the wire, this innovative technique eliminates the need for an external gas shield, making it more versatile and cost-effective.

This process opens up opportunities for outdoor and remote welding applications where traditional TIG methods would fall short. The flexibility of TGX welding allows for increased productivity and efficiency without compromising on quality, making it a game-changer in the welding world.

What Are Alternatives Methods to TIG welding without Gas?

TIG welding without gas can be avoided with the help of modern welding units that are both TIG welders and stick welders. Having an old machine that is only a TIG welder stops you from performing more difficult projects. So, you can buy a TIG/Stick welder and sell your old machine.

🌟– This way, you have a newer with more advanced features for the money machine. Therefore, you can handle more difficult tasks, you become more versatile and you have financed that with your old machine.

🌟– You can check my top picks on TIG machines in another article that I wrote. For amateur welders, I recommend this affordable Weldpro TIG/Stick Welder, and for professionals, this high-duty cycle Lotos TIG/Stick Welder.

🌟– Now, if you already have a good stick welder you can use it instead. Make sure to use small diameter electrodes because the weld pool will be much larger in stick welding. I recommend these US Forge electrodes for this scenario that a welder of any skill can use.

🌟– The best alternative to Argon gas is Flux-cored arc welding (FCAW). In FCAW, there is no need for an external shielding gas because the flux inside the core of the electrode provides enough shielding to the process. In FCAW, liquid slag is produced that shields the weld. The consumable electrodes are used in FCAW and they have tubular orientations that are filled with flux.

🌟– In actual cases, there are many other ingredients in the core of the electrode other than the flux only. These ingredients help in protecting the welding arc at higher temperatures. The welding process is very popular because it offers high penetration rates into the base metals.

🌟– It is easier to handle and it offers a diverse range of materials on which it can be performed. Usually, when the welding is performed without gas, welders prefer Flux Core over TIG welding.

How to Perform TIG welding without Gas?

It is uncommon to not use gas with this method. However, performing TIG welding without gas is not an easy job. Whenever the term ‘TIG welding without gas’ is mentioned, it means the involvement of TIG wire with flux core.

No external shielding gas is used and the shielding effect is produced with the burning of the flux during the welding process. It requires high skills and some preventions. The methodology for performing TIG welding without gas is given in this section.

- The first step is to make sure the safety of the welder. Either you are a professional welder or a beginner, welding processes demand proper safety and precaution measures. During the different welding processes, high temperatures are achieved and they can cause damage to the welder and the equipment. Therefore, it is important to check all the safety equipment before initiating the welding process.

- Also, the workpiece and workspace must be 100% clean.TIG welding has an advantage that dirty work-pieces can be weld in a decent way. However, if one of the metal is dirty and the other one is clean, the difference will remain there after performing the welding. Considering the fact that you don’t use a gas, it creates lots of problems. So, cleaning and brushing are essential.

- The next step is grinding and preparation of the joint.

- Start the welding process. While performing TIG welding without gas, stay as much consistent as you can. When the TIG welding is performed without gas, excessive and noxious smokes are produced that do not let the welders see into the weld pool. Beginners must spend some time on increasing their consistency. You can cover more area to mitigate the lack of strength but it will also further decrease the already extremely low toughness.

- After the completion of the process, you have to clean the weld area and base metal again.

General Tips For TIG Welding

After getting a clear understanding of the TIG welding without gas, some of the tips about TIG welding, in general, are given here:

- The welders do not need to carry large and heavy gas cylinders with them. In case gas is required, small-sized cylinders can be used instead of heavy ones because weight might create problems. Heavy cylinders weigh more than 200 pounds and it is difficult to place them on a welding cart. They are also hazardous and can cause a severe accident in case of falling over.

- TIG welding with gas can produce neat welds on dirty metals.

- The welder is difficult to see into the weld pool without shielding gas

- TIG welding can result in hazardous smokes and fumes. So, ventilation is very important.

- TIG welding without gas takes more time than TIG welding with Argon or Helium.