What is a Weld Puddle in Welding?

A weld puddle is a molten pool of metal that forms when two pieces of metal are joined together through welding. The size and shape of the weld puddle depend on a number of factors, including:

- the type of welding process being used,

- the angle at which the weld is being made,

- the amount of heat being applied,

- and the speed at which the weld is being made.

One of the most important things to remember when welding is to keep the weld puddle small. A large weld puddle can lead to a number of problems, including:

- poor weld quality,

- excessive heat build-up,

- and metal slag inclusion.

What is Puddle arc welding?

Puddle arc welding (PAW) is a type of welding in which the weld puddle is kept under control by using an electrode that is constantly dipped into the puddle. This helps to keep the size and shape of the puddle consistent, which leads to better weld quality.

Stick welding puddle

Stick welding, also known as shielded metal arc welding (SMAW), is a type of welding in which the weld puddle is kept under control by using a stick electrode that is dipped into the puddle.

How do you control weld puddles?

There are a number of ways to control weld puddles, including:

- using the correct welding process,

- applying the correct amount of heat,

- and welding at the correct speed.

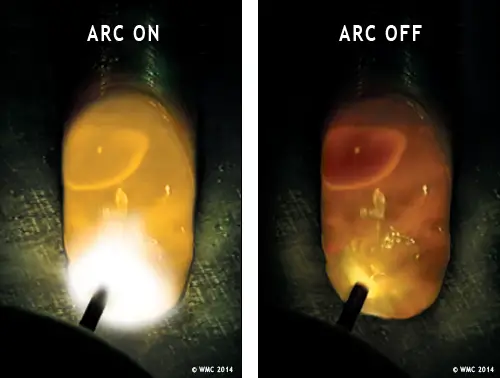

How to see Weld Puddle?

Observing the weld puddle is an essential skill for welders to ensure proper control and quality of the welding process. Here are some techniques to see the weld puddle:

Welding Helmet

welding helmet with a suitable lens shade is crucial for protecting your eyes from the intense brightness of the welding arc. It also allows you to see the weld puddle clearly. Ensure that the lens shade is appropriate for the welding process being used, as different processes may emit different levels of light intensity.

Arc Viewing Lens

Some welding helmets have built-in arc viewing lenses or auto-darkening filters that provide a clear view of the weld puddle while protecting your eyes from harmful light. These lenses automatically adjust the shade level to the brightness of the arc, allowing you to see the weld puddle without manually lifting or adjusting the helmet.

Proper Lighting

Adequate lighting conditions in the welding area are essential for accurate observation of the weld puddle. Insufficient lighting can make it difficult to see the details of the molten metal. Ensure that the workspace is well-lit to enhance visibility.

Welding Technique

The way you position yourself and manipulate the welding torch or electrode can affect your view of the weld puddle. Position yourself at an angle that provides a clear line of sight to the weld joint and puddle. Maintain a steady hand and control the torch or electrode movement to ensure the desired weld puddle formation.

Practice and Experience

Developing the ability to see and interpret the characteristics of the weld puddle takes practice and experience. Over time, you will become more familiar with the visual cues and changes in the shape, size, and color of the weld puddle, allowing you to make necessary adjustments and ensure proper weld quality.

Remember, safety is paramount when observing the weld puddle. Always wear appropriate personal protective equipment (PPE) and follow safety guidelines to protect yourself from harmful radiation, sparks, and fumes generated during welding.