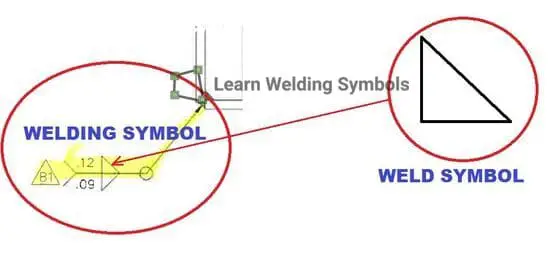

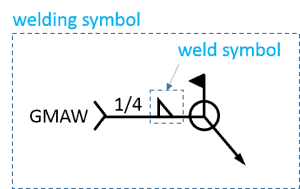

Where on a welding symbol can you find information about the welding process to use for the weld?

Information about the welding process to use for a weld can be found in the tail of the welding symbol on a welding symbol.

The tail is the extended line connected to the reference line of the welding symbol. It contains additional information related to the welding procedure, including the welding process to be employed.

The specific welding process is typically represented by a code or abbreviation, such as:

- “SMAW” for Shielded Metal Arc Welding,

- “GMAW” for Gas Metal Arc Welding,

- “GTAW” for Gas Tungsten Arc Welding, or

- “FCAW” for Flux-Cored Arc Welding.

The welding process information in the tail of the welding symbol helps communicate the specific method to be used for the weld.

Why is a tail added to the basic welding symbol?

A tail is added to the basic welding symbol to provide additional information and specifications about the weld. It serves as an extension of the reference line and allows for the inclusion of important details related to the welding process, joint preparation, filler material, and other relevant instructions.

The tail helps to convey specific requirements that may not be fully represented within the basic welding symbol alone. It allows for clear communication between designers, engineers, and welders, ensuring that everyone involved in the welding process understands the necessary specifications.

By adding a tail to the basic welding symbol, important information can be included, such as weld dimensions, welding process, welding parameters, heat treatment requirements callout, or any other pertinent details. This helps ensure that the weld is performed correctly and meets the desired specifications.

What is the purpose of the tail used on the welding symbol?

- The tail on a welding symbol serves as an extension of the reference line.

- It provides additional information and specifications about the weld.

- The tail allows for the inclusion of important details related to the welding process, joint preparation, filler material, and other relevant instructions.

- It helps convey specific requirements that may not be fully represented within the basic welding symbol alone.

- The tail enables clear communication between designers, engineers, and welders regarding necessary specifications.

- Important information, such as weld dimensions, welding process, welding parameters, and heat treatment requirements, can be included in the tail.

When is the tail omitted from a welding symbol?

The tail on a welding symbol is typically omitted when the information regarding the welding process, joint preparation, or other specifications is adequately conveyed within the basic welding symbol.

In such cases, the additional information is not necessary, and the tail is not included to avoid cluttering the welding symbol.

rsw in the tail of the welding symbol refers to what?

The abbreviation “RSW” in the tail of a welding symbol typically refers to “Resistance Spot Welding.”

Resistance spot welding is a welding process that involves applying pressure and passing an electric current through the materials being joined to create a weld.

This process is commonly used for joining thin sheet metal or other materials that are resistant to thermal distortion.

The inclusion of “RSW” in the tail of a welding symbol indicates that resistance spot welding is the specified welding process to be used for the particular weld.