Spot welding is a widely used welding technique that involves joining metal surfaces by applying heat and pressure at specific points. This technique is commonly used in manufacturing and construction industries to create fast, reliable and high quality welds.

To ensure that spot welding is performed correctly and consistently as per drawing requirements, spot welding symbol is very important to follow. In this article, we will explore the importance of the spot welding symbol and how it is used in welding applications.

What is spot welding?

Spot welding is a welding technique that involves joining two metal surfaces by applying heat and pressure at specific points. This is achieved by passing an electric current through two copper electrodes, which clamp the metal surfaces together. The heat generated by the electric current melts the metal surfaces, and the pressure applied by the electrodes fuses them together to create a strong and durable weld.

Spot welding symbols

Spot welding symbols are graphical representations used in welding drawings or blueprints to indicate the location and size of spot welds.

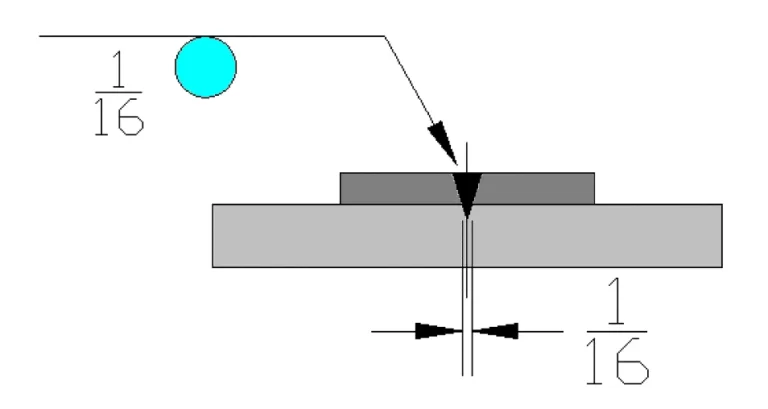

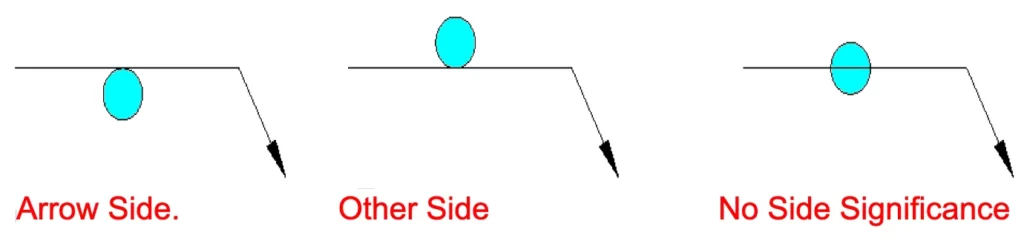

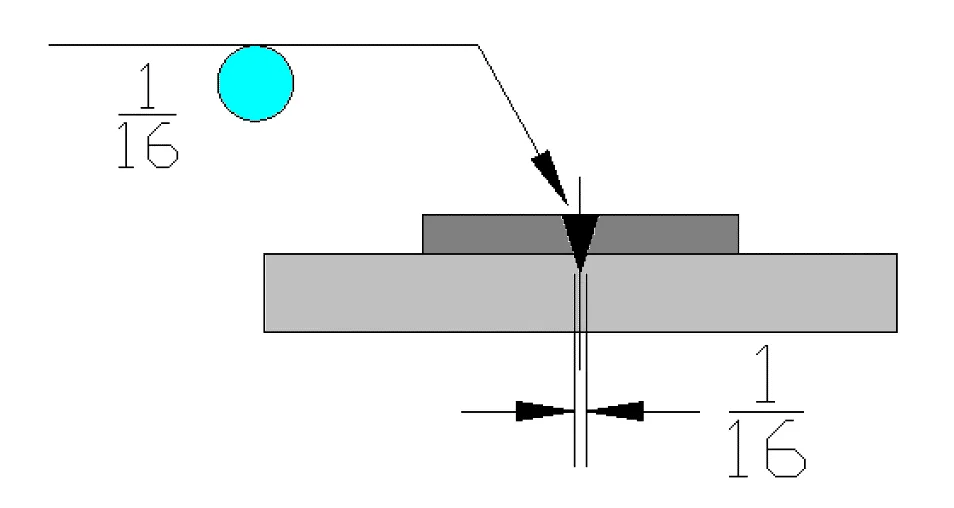

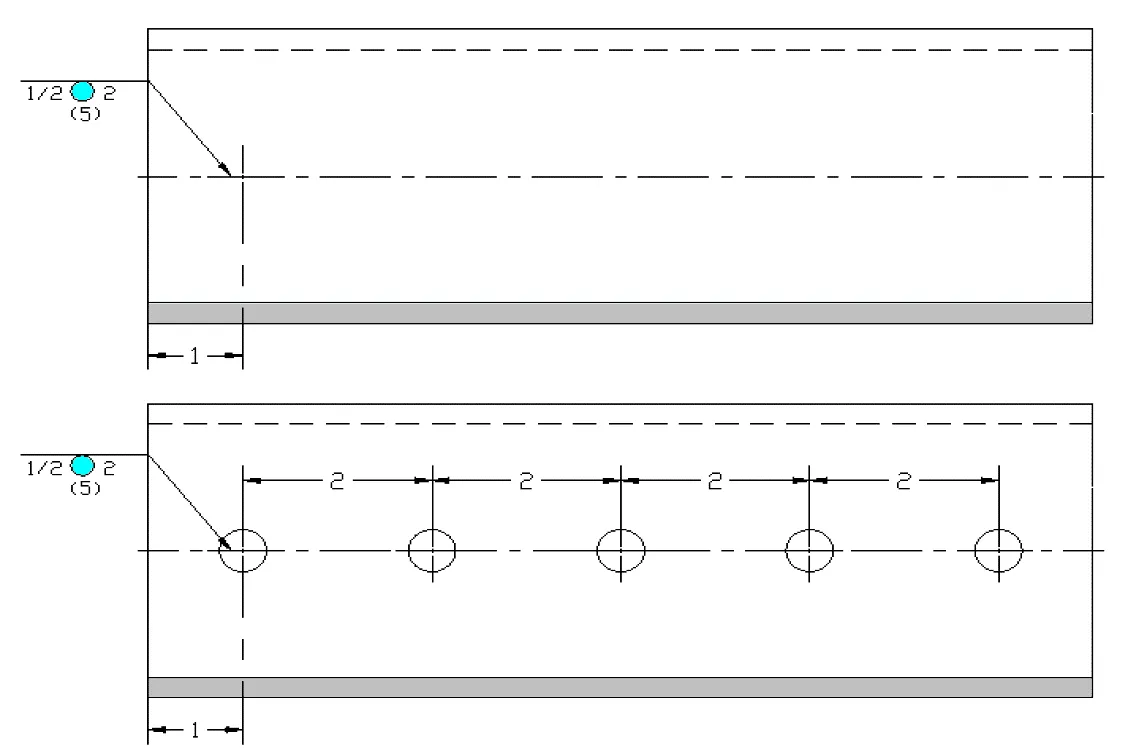

To represent a spot weld, a circle symbol can be placed above, below or at the centre of the reference line. If the symbol is at the centre, it means that there is no preference for either side. This type of weld can be made using a resistance spot welder, which is often used in sheet metal work.

The diameter of a spot weld is denoted on the left side of the welding symbol. This measurement represents the size of the weld at the faying surface, which is where two parts are placed in close proximity to each other.

If multiple spot welds are needed, the number required will be indicated in parentheses above or below the welding symbol, depending on where the symbol is located. If the symbol is centered on the reference line, the number of required welds can be placed above or below the symbol.

Spot Weld Callout

The spot weld symbol may also include the pitch, which is denoted on the right side of the symbol. When a pitch is specified, it means that the welds are to be applied at regular intervals along the entire length of the part.

For instance, if the part is 20 inches long and the pitch is 2 inches, then the welding symbol would be used every 2 inches along the length of the 20 inch part. If the spot welding will not cover the full length of the part, this information needs to be communicated on the print using dimension lines.

Elements of a spot welding symbol

The spot welding symbol consists of a circle placed on the reference line. The size of the circle represents the diameter of the weld, and the arrow indicates the location of the weld on the joint.

Spot welding applications

Spot welding is commonly used in manufacturing and construction industries to create strong and durable welds. It is used to join a wide range of metal surfaces, including sheet metal, wire mesh, and metal tubes. Spot welding is also used in the automotive industry to join body panels, frames, and other metal components.

Conclusion

The spot welding symbol is a critical welding symbol used in welding applications to indicate the location and size of spot welds. It provides essential information to the welder and other members of the team and helps to ensure the quality and strength of the weld. By understanding the spot welding symbol and its variations, welders can perform spot welding correctly and consistently, resulting in high-quality and durable welds.