Shop Weld vs Field Weld Symbol

Welding symbols play a crucial role in conveying important information about welds on engineering drawings. Among these symbols, the shop weld symbol and the field weld symbol hold significant importance.

In this blog post, we will focus on the field weld symbol, which represents a weld made at a location other than a shop or the place of initial construction. Conversely, shop welds are performed in workshops or controlled manufacturing environments.

What is a Shop Weld?

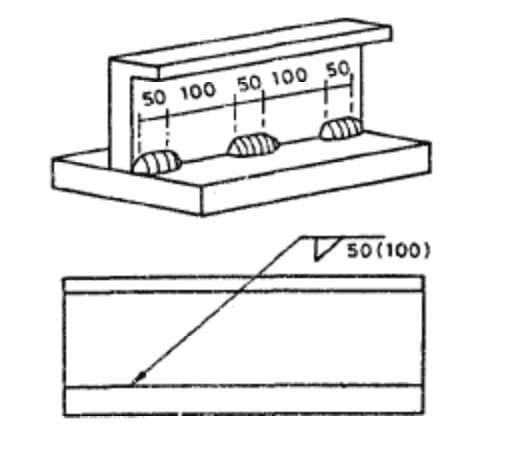

A shop weld refers to a welding operation that takes place in a controlled environment, typically within a workshop or fabrication shop. It is the process of joining two or more metal pieces together using various welding techniques, such as arc welding, MIG welding, TIG welding, or spot welding, among others.

A Shop weld only refers to weld made in workshop and it can be of any type such as Fillet weld, groove weld or any other type.

What is a Field Weld?

A field weld refers to a welding operation that occurs at the construction site or field location where the final structure or assembly is being erected or installed. Unlike shop welding, which takes place in a controlled workshop environment, field welding is performed outdoors or in less controlled conditions.

Field welding is necessary when components or sections of a structure cannot be fully fabricated or connected in a shop and need to be joined on-site. This type of welding is commonly used in construction projects involving steel structures, pipelines, bridges, or other large-scale installations.

Field welding requires portable welding equipment, and welders must consider factors such as weather conditions, accessibility, and safety measures while performing the welds.

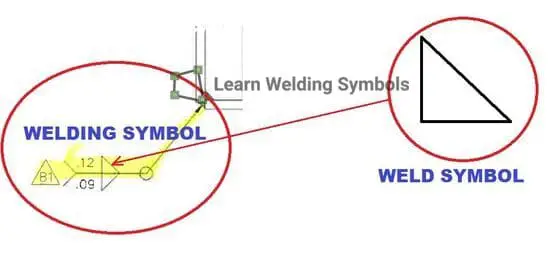

Understanding the Shop Weld Symbol

The shop weld symbol is used to represent welds that are intended to be performed in controlled shop environments, typically at the fabrication facility or workshop.

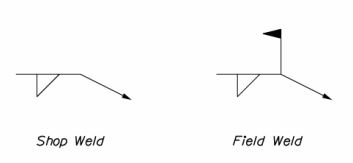

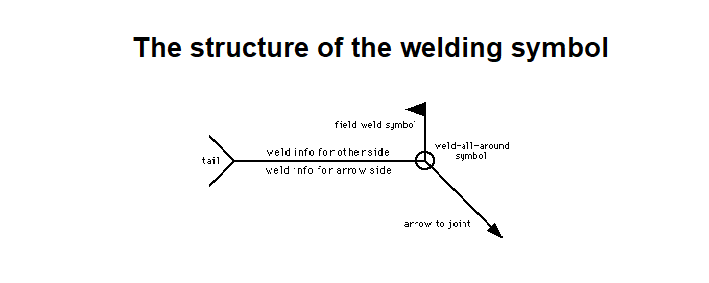

It signifies that the welding operation is conducted under controlled conditions, allowing for better quality control and consistency. The shop weld symbol is often depicted as a small flag or triangle located at the intersection of the reference line and the arrow or leader line.

Decoding the Field Weld Symbol

On the other hand, the field weld symbol is employed to denote welds that are executed on-site, directly at the installation or construction location. These welds are performed in the field, away from the controlled environment of a workshop.

The field weld symbol typically appears as a small circle situated at the intersection of the reference line and the arrow or leader line.

What is the difference between field weld and shop weld?

The main differences between field welding and shop welding are:

- Location: Field welding is done on-site during construction, while shop welding is done in a controlled workshop environment.

- Environment: Field welding is performed outdoors or in less controlled conditions, while shop welding benefits from a controlled environment.

- Equipment: Shop welding uses specialized equipment found in the workshop, while field welding requires portable equipment.

- Quality Control: Shop welding allows for better quality control measures, while field welding may face challenges in maintaining consistent quality.

- Accessibility: Shop welding offers better access to the workpieces, while field welding may require additional measures for access.

In summary, field welding is performed on-site in outdoor conditions with portable equipment, while shop welding is done in a controlled workshop environment with specialized equipment and better quality control measures.

Shop weld vs field weld symbol meaning

In welding, the terms “shop weld” and “field weld” can also refer to specific symbols used in welding drawings or blueprints to indicate where the welding operation should take place. The shop weld symbol is represented by a filled-in circle and is used to indicate that the welding operation is to be performed in a controlled shop environment.

On the other hand, the field weld symbol is represented by an unfilled circle and is used to indicate that the welding operation should be carried out on-site or in the field during construction. These symbols provide clear instructions to the welders and help ensure that the welding is performed in the appropriate location.

Distinguishing Characteristics

- Location: The primary distinction between shop welds and field welds lies in their execution location. Shop welds are conducted in a controlled workshop environment, whereas field welds are performed on-site at the construction or installation location.

- Quality Control: Shop welds benefit from better quality control measures due to the controlled conditions in which they are executed. The fabrication facility provides a controlled environment with optimal equipment, material preparation, and inspection processes. Field welds, on the other hand, face challenges related to environmental factors, limited space, and potential access limitations, which can impact quality control.

- Efficiency and Schedule: Shop welds can be completed efficiently in a dedicated workshop, allowing for better planning and scheduling. Field welds, on the other hand, are subject to site conditions, weather constraints, and logistical complexities, potentially leading to schedule adjustments and delays.

- Inspection and Testing: Both shop and field welds are subject to inspection and testing to ensure compliance with applicable codes and standards. However, the inspection process for field welds may involve additional challenges due to the on-site location, making access and inspection techniques more demanding.

Collaboration and Communication

Clear communication between welding engineers, designers, and welding teams is vital to ensure the proper identification and execution of shop and field welds. Collaboration during the design phase and continuous communication throughout the project can help clarify the requirements, address any ambiguities, and ensure that the correct symbols are used to represent the intended weld locations.