a3, a4 Welding Symbol meaning

As a welding engineer, I often come across various welding symbols in my line of work. Among them, the A3 and A4 welding symbols hold particular significance, as they represent fillet welds with specific throat sizes.

In this article, I will provide a comprehensive explanation of these symbols, shedding light on their meaning and importance in welding design and engineering.

What is a Fillet Weld?

A fillet weld is a common type of weld used to join two pieces of metal that are perpendicular or at an angle to each other. It is characterized by a triangular-shaped weld deposit that fills the gap between the two components along their edges or surfaces.

The term “fillet” refers to the concave junction formed by the weld.

Fillet welds are widely used in various industries and applications due to their versatility and strength. They provide a strong connection between components and distribute loads and stresses evenly across the joint.

How to size a fillet Weld?

When sizing a fillet weld, you have two primary methods:

- Sizing by throat size (a) and

- Sizing by leg length (z).

Let’s explore both methods:

- Sizing by Throat Size (a):

The throat size of a fillet weld refers to the distance from the starting point of the joint root to the point where the two weld surfaces intersect, measured perpendicular to the hypotenuse of the largest right triangle that can fit within the cross section of the weld. This measurement assumes that there is no gap or opening between the components being welded. - To size a fillet weld using the throat size (a), you follow these steps:

- a. Determine the required throat size specified in the welding design or code.

- b. Measure the throat size perpendicular to the hypotenuse of the fillet weld triangle.

- c. Ensure that the actual throat size of the weld matches or exceeds the specified throat size.

Sizing by throat size is often used when the weld size is critical, and the leg length is not explicitly specified.

- Sizing by Leg Length (z):

The leg length of a fillet weld represents the height or vertical distance from the root of the weld to the leg of the triangle. To size a fillet weld using the leg length (z), follow these steps:

- a. Determine the required leg length specified in the welding design or code.

- b. Measure the leg length perpendicular to the reference line of the welding symbol.

- c. Ensure that the actual leg length of the weld matches or exceeds the specified leg length.

Sizing by leg length is commonly used when the weld size is specified explicitly, and the throat size is not critical.

It’s important to note that the throat size (a) and leg length (z) are related to each other. The throat size is approximately 0.7 times the leg length for most fillet welds. However, specific codes and standards may provide different formulas or factors to determine the relationship between throat size and leg length.

When sizing a fillet weld, always refer to the welding design, code, or specification provided for the project. These documents will outline the required throat size, leg length, or other relevant dimensions based on the specific application, material properties, and load requirements.

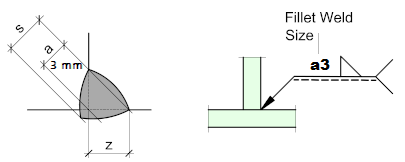

Understanding the A3 Welding Symbol

The A3 welding symbol signifies a fillet weld with a throat size of 3 mm. The throat size refers to the effective leg length of the fillet weld, which is the distance from the root of the weld to the theoretical intersection of the two weld surfaces.

When encountering the A3 symbol on a welding drawing, it indicates that a fillet weld with a throat size of 3 mm is required at the specified location.

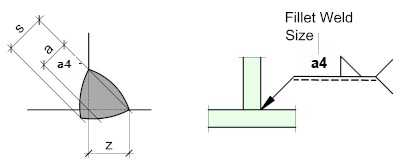

Decoding the A4 Welding Symbol

Similar to the A3 symbol, the A4 welding symbol also represents a fillet weld. However, the throat size associated with the A4 symbol may vary. It is important to note that the throat size should be explicitly provided alongside the symbol on the welding drawing.

For instance, if the throat size is specified as 4 mm, the A4 symbol would indicate the need for a fillet weld with a throat size of 4 mm at the designated location.

Importance of Understanding Fillet Weld Symbols

Properly interpreting and understanding fillet weld symbols is crucial for welders, fabricators, and inspectors alike. These symbols serve as a common language that facilitates effective communication between engineering teams and welding professionals. By accurately deciphering the symbols, welders can precisely execute the required welds, ensuring the integrity and strength of the joint.

Tips for Working with Fillet Weld Symbols

To effectively work with fillet weld symbols, it is essential to pay attention to the details provided alongside the symbols on the welding drawing. Note any specified throat sizes, dimensions, or other relevant information related to the fillet weld. This information guides the welder in selecting the appropriate welding technique, electrode size, and joint preparation to achieve the desired weld quality.

Collaboration and Communication

Clear communication between welding engineers, designers, and welders is vital to ensure that the intended weld specifications are understood and executed correctly. Regular collaboration and open dialogue among these stakeholders can help address any potential ambiguities or discrepancies in the welding symbols, ensuring a smooth and efficient welding process.