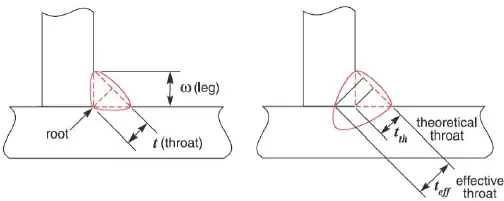

Effective throat thickness in welding refers to the distance measured from the root of the weld to the face of the fillet along the axis of the weld.

This measurement is crucial in determining the strength of a fillet weld. Choosing the appropriate effective throat thickness is important to ensure weld integrity and prevent issues like cracking and distortion.

What is the throat thickness of a fillet weld?

The throat thickness of a fillet weld refers to the minimum distance between the root and the face of the weld, measured along the axis of the weld. It represents the effective amount of weld metal that contributes to the strength of the joint.

The throat thickness is an important parameter in determining the structural integrity and load-carrying capacity of a fillet weld.

The throat thickness of a fillet weld is the distance from the root to the center of the face of the weld.

As an approximate rule, it is commonly accepted that the throat thickness is approximately 0.7 times the leg length of the fillet weld.

This estimation is often used in practical applications, as the slight variation from the exact value does not significantly impact the functionality or use of the welded item. Therefore, using 0.7 as a value is considered sufficiently close for most welding purposes.

Factors Affecting Effective Throat Thickness

Several factors influence the effective throat thickness:

- Weld Angle: The angle of the weld affects the depth of penetration of the welding arc. Deeper penetration results in a smaller effective throat thickness.

- Weld Bead Size: The size of the weld bead directly impacts the effective throat thickness. Larger weld beads tend to have a smaller effective throat thickness.

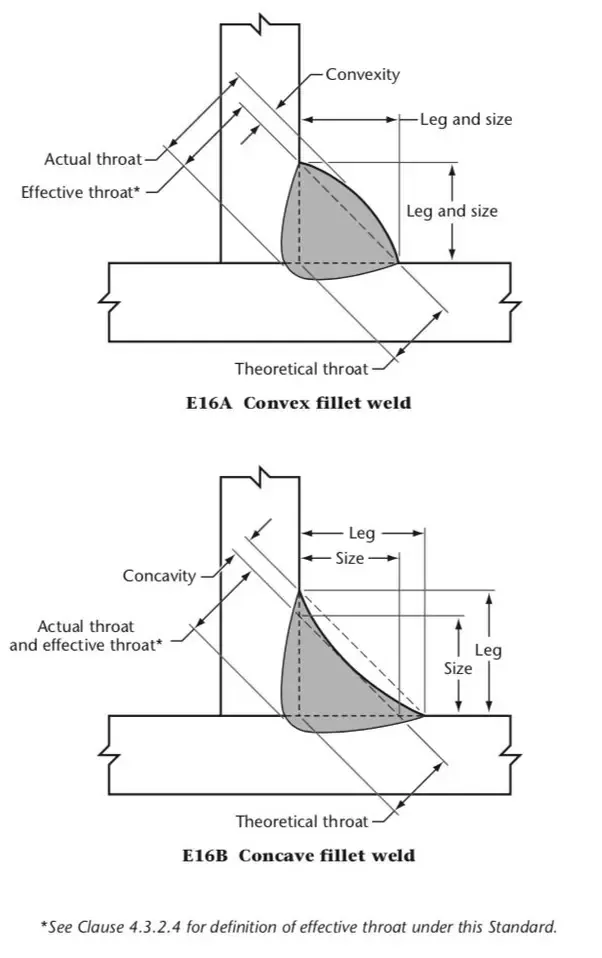

- Weld Convexity: Convexity refers to the curvature of the weld bead. A more convex weld bead will have a smaller effective throat thickness compared to a less convex one.

Calculation of Effective Throat Thickness

The effective throat thickness of a weld can be calculated using the formula:

- Effective Throat Thickness(a) = Minimum Distance – Convexity

The minimum distance represents the shortest distance between the root of the weld and the face of the fillet. Convexity refers to the amount of curvature present in the weld bead.

Effective Throat Thickness for Concave & Convex Fillet Weld

In Canada, the code for structural welding is W59 – Welding Steel Construction, which specifies the following regarding fillet welds:

- 4.3.2 Fillet Welds

- 4.3.2.1 – The effective area of a fillet weld is calculated by multiplying the effective weld length with the effective throat.

- From the above statement, we understand that the effective throat plays a crucial role in determining the effective area.

- 4.3.2.4 – The effective throat (E) is defined as the shortest distance from the root to the face of the diagrammatic weld, except for SAW (Submerged Arc Welding) processes.

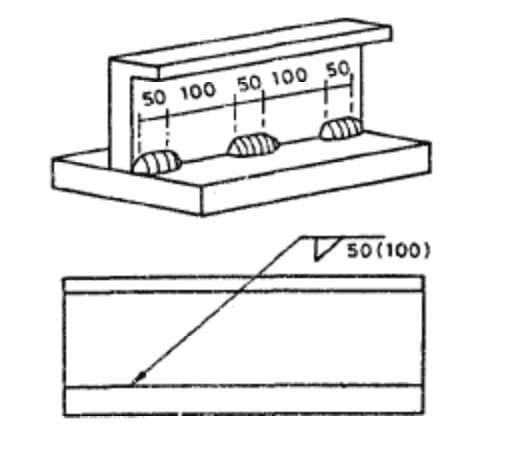

A fillet weld consists of several components, including the root, face, legs, and toes. Typically, a fillet weld is created with equal legs and a flat profile on the face, ensuring smooth transition from the bead to the parent metal at the toes. The resulting weld forms a right-angled triangle with equal legs.

As depicted in the diagram below, the effective throat is measured from the depth of penetration in the root to a line drawn from one toe to another across a flat or convex face.

In the case of a weld with a concave face, the measurement is taken from the lowest point of the face, which also reduces the effective area of the fillet weld. If the fillet has unequal legs, the measurement is taken from the smaller leg, further reducing the effective area of the weld.

Understanding Effective Area of a Weld

The effective area of a weld refers to the cross-sectional area of the weld that contributes to the joint’s overall strength. It is typically smaller than the total cross-sectional area of the weld since only a portion of the weld bead is in contact with the base metal.