This post covers What is Seal welding & seal welding symbols with examples. If you’re a welder, a fabricator, an engineer, or someone who frequently interacts with welding drawings, you’ve likely come across these symbols. So, let’s learn seal welding symbols and help clear up any confusion.

The Basics of Welding Symbols

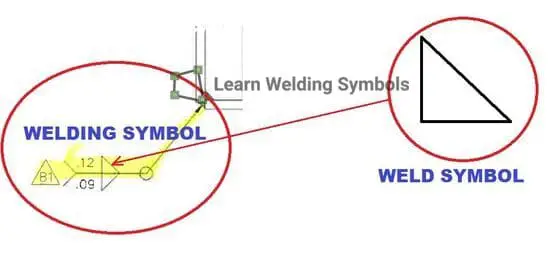

Before we dive into seal welding symbols specifically, let’s review what welding symbols are. Welding symbols are a set of standardized symbols used on welding blueprints or drawings to communicate how welds should be performed. They provide important information such as the type of weld, size, length, and other details necessary to complete the weld correctly.

What is Seal Welding?

The term “seal weld” is defined in the AWS A3.0 Standard Welding Terms and Definitions as a weld specifically designed to ensure a certain level of leakage resistance. The main function of a seal weld can be to confine a fluid, which could be in a gaseous or liquid state.

In sectors like mechanical and structural engineering, seal welds are commonly utilized not necessarily to keep a fluid from leaking out of a container, but rather to stop a fluid from infiltrating an area where it might cause damage, typically through corrosion.

In such industries, it’s commonplace to use seal welds as a preventive measure against the ingress of moisture and oxygen-enriched air and water into a particular cavity.

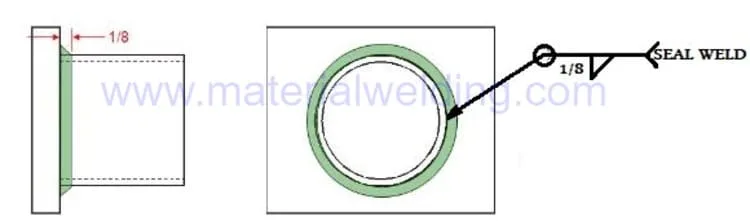

Seal welding is a process used to prevent leakage in a joint by welding a leak proof weld. Remember Seal Weld are non-strength welding joint to prevent leak. This technique is commonly used in the fabrication of tanks, pipelines, and other equipment where a leak-proof joint is essential. Seal welds are predominately used in heat exchangers tube to tubesheet welding joints.

Identifying Seal Welding Symbols

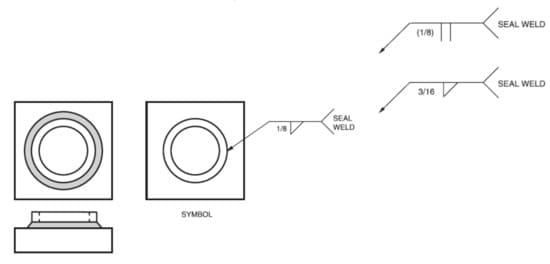

Now, let’s discuss how to identify a seal weld on a drawing. Seal welds are not a specific type of weld, but rather a function of a weld. Therefore, they may not have a specific symbol defined in AWS A2.4 or ISO 2553. The need for a seal weld is often indicated in the tail of the welding symbol by mentioning SEAL WELD as shown in below example, where additional instructions can be provided.

The tail of the welding symbol is the forked end, which looks a bit like a fish’s tail. This area of the symbol can contain various types of information, such as the welding process to be used, the specification, or other pertinent details. If a weld is to be used as a seal weld, it may be indicated here with a note such as “SEAL WELD”.

Examples of Seal Welding Symbols

Since seal welds can be created using different types of welding processes, the symbols used can vary. For example, if a fillet weld is used as a seal weld, the standard triangular symbol for a fillet weld will be used, and the tail of the symbol would include the notation “SEAL WELD” as we noticed earlier or no by giving a backing run (sealing run) weld symbol as shown in below examples.

Similarly, if a groove weld is used for sealing, the symbol would reflect the specific type of groove weld (for example, a square groove weld, V-groove weld, etc.), and again, the tail would include the note “SEAL WELD” or use a sealing run symbol.

Conclusion

Seal welding plays a critical role in many industries, ensuring that joints are secure and leak-free. While there is no specific symbol for a seal weld, understanding how to identify this requirement in the tail of a welding symbol is crucial for the correct execution of the weld.

Remember, welding symbols are a language in themselves – learning to interpret them accurately is key to successful welding projects.