Codes & Standards for Welding Symbols

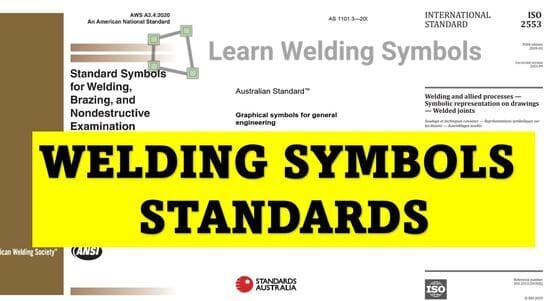

Welding symbols are graphical representations that are used to communicate how welding operations are to be performed. There are a number of standards that define the specifics of welding symbols, including American standard (AWSA2.4), International standard (ISO 2553), and EN 22553, which is identical to ISO 2553.

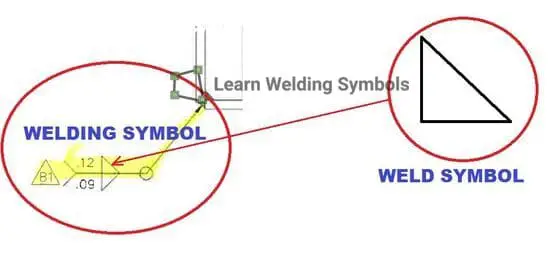

In the UK, the terms ‘weld symbol‘ and ‘welding symbol‘ are often used interchangeably, although they signify different concepts according to the American standard on symbols.

A weld symbol delineates the type of weld required along with the basic weld symbols, such as basic V, U, or a triangle. These symbols respectively represent single-V, single-U, or fillet welds.

The welding symbol, on the other hand, encompasses the weld symbol and additional information. This extra information includes a reference line where weld symbols can be appended, and an arrow line indicating the position of the welded joint. Other elements, such as weld sizes and lengths, the welding process, and requirements for non-destructive testing, may also be added to the welding symbol.

AWS 2.1 DC: Welding Symbol Chart (desk Size)

AWS 2.1 WC: Welding Symbol Chart (Wall Size)

ANSI/AWS A2.4, Standard Symbols for Welding, Brazing, and Nondestructive Examination

This is the most widely used standard in the US. It defines all the elements of a welding symbol, including the arrow, the reference line, the weld symbol, the dimensions and other pertinent information.

The ANSI/AWS A2.4 standard is a widely recognized reference for the standardized symbols used in welding, brazing, and nondestructive examination (NDE). Developed jointly by the American Welding Society (AWS) and the American National Standards Institute (ANSI), this comprehensive standard provides a common language for communicating welding and NDE specifications and requirements in technical drawings and blueprints.

The standard encompasses a broad range of symbols, including those for various types of welds, brazes, and NDE methods. It establishes clear guidelines for the visual representation of these symbols, ensuring consistent interpretation and understanding across different industries and applications.

ISO 2553 Welding and allied processes: Symbolic representation on drawings- Welded joints

The international standard which is very similar to ANSI/AWS A2.4. Most countries outside the USA use ISO 2553.

ISO 2553:2019(en) is an internationally recognized standard that provides guidelines for the symbolic representation of welded joints on technical drawings. Developed by the International Organization for Standardization (ISO), this standard establishes a common language and format for communicating welding information and specifications in engineering and manufacturing industries.

The standard outlines the symbols and conventions used to represent various types of welded joints, including butt joints, fillet joints, corner joints, T-joints, and more. It defines the graphical elements, such as reference lines, arrow lines, and dimensions, used to depict welding details accurately.

BS EN 22553 Welded, brazed and soldered joints – Symbolic representation on drawings

The European standard, adopted in many countries in Europe and Asia. Very similar to ISO 2553.

BS EN 22553 is a British Standard that provides guidelines for the symbolic representation of welded, brazed, and soldered joints on technical drawings. It is based on the international standard ISO 2553, with additional British-specific requirements and recommendations.

This standard establishes a common language and format for communicating welding, brazing, and soldering information and specifications in engineering and manufacturing industries. It defines the symbols and graphical elements used to represent different types of joints, including welds, brazes, and solders.

AS 1101.3 Graphical symbols for general engineering, Part 3: Welding and non-destructive examination

AS 1101.3 is an Australian Standard that specifies graphical symbols used in technical drawings and diagrams. It includes a section on welding, brazing and soldering symbols that are used to indicate the type and extent of welding on drawings.

AS 1101.3 is an Australian Standard that focuses on graphical symbols for general engineering, specifically addressing welding and non-destructive examination (NDE) processes. This standard provides a comprehensive set of symbols used to represent welding and NDE details on technical drawings and engineering documentation.

AS 1101.3 establishes a standardized language and visual representation system for communicating welding and NDE specifications and requirements in engineering and manufacturing industries in Australia. It covers a wide range of symbols, including those for various types of welds, joints, weld dimensions, weld quality, and NDE methods.

The key elements of a welding symbol according to these standards are:

- Arrow: Points to the weld joint.

- Reference line: An imaginary line to which the weld symbol and other elements relate.

- Weld symbol: Represents the type of weld, e.g. fillet weld, groove weld, etc. Typically placed on the reference line.

- Dimensions: Represent the size of the weld. Given on either the left side or right side of the reference line.

- Tail: A line following the reference line. Contains specifications and other supplementary information about the weld.

- Process: Specifies the welding process, e.g. SMAW, GMAW, etc. Located on either side of the reference line.

- Specifications: Details like joint geometry, welding position, surface condition, etc. Placed on the tail.

- Other information: Includes notes, legends, etc. to provide additional details. Usually located at the bottom of the welding symbol.

So welding symbols provide a concise way to communicate important welding operation instructions to fabricators and welders. By following a standard, they can be universally understood.