What is puddle weld?

A puddle weld, also known as a plug weld or rosette weld, is a type of weld commonly used in metal fabrication and welding processes. It involves creating a small weld deposit or “puddle” at the intersection of two overlapping metal surfaces.

The weld is typically made by melting the base material and adding filler metal, if necessary, to create a strong bond between the two surfaces.

Puddle welds are often used to join two or more metal components together, particularly when access to the backside of the joint is limited or not possible. They are commonly employed in applications such as sheet metal fabrication, automotive manufacturing, structural steel construction, and general metalwork.

Puddle Weld Symbol

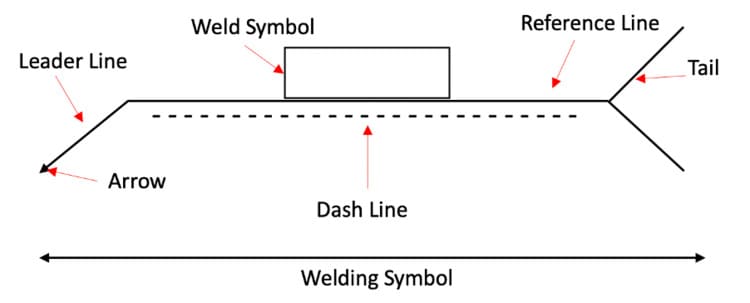

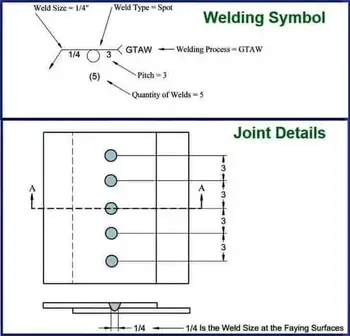

The puddle weld symbol is a graphical representation used on engineering drawings to indicate the location and specifications of a puddle weld. It provides essential information for welders and fabricators, ensuring that the weld is executed correctly. The symbol consists of various elements that convey specific details about the weld.

Here is a description of the components typically included in a puddle weld symbol:

- Reference Line: The symbol begins with a horizontal reference line, which represents the base material or the surface where the weld is to be applied.

- Weld Symbol: A small circle or dot is placed at the intersection of the reference line to indicate the location of the puddle weld.

- Weld Size: The size or diameter of the puddle weld is indicated by placing a dimension value alongside the weld symbol. This value specifies the desired size of the weld in inches or millimeters.

- Additional Specifications: Additional information about the weld may be included alongside the symbol or in a separate note. This can include details such as the weld process, filler metal, weld quality requirements, or any other specific instructions.

Puddle Weld Applications

Puddle welds find applications in various industries and fabrication processes where joining metal components is required. Some common applications of puddle welds include:

- Sheet Metal Fabrication: Puddle welds are frequently used in sheet metal fabrication to join thin metal sheets together, creating structures such as boxes, enclosures, and panels.

- Structural Steel Construction: Puddle welds are employed in the construction of steel structures, such as buildings, bridges, and industrial facilities. They are used to connect steel beams, columns, and other structural members.

- Automotive Manufacturing: Puddle welds are utilized in the assembly of automotive components, including chassis, body panels, brackets, and frames. They provide strength and rigidity to the joined parts.

- Pipe and Tube Fabrication: Puddle welds are employed in pipe and tube fabrication processes to create connections between sections of piping or tubing. They are commonly used in applications such as plumbing, HVAC systems, and industrial pipelines.

- General Metalwork: Puddle welds are found in various general metalwork applications, such as the fabrication of furniture, machinery, equipment, and agricultural implements. They are used to join metal components and provide structural integrity.

- Repair and Maintenance: Puddle welds are often employed in repair and maintenance work, where damaged or worn-out metal components need to be restored or reinforced. They can be used to repair cracks, reinforce weakened areas, or replace missing material.

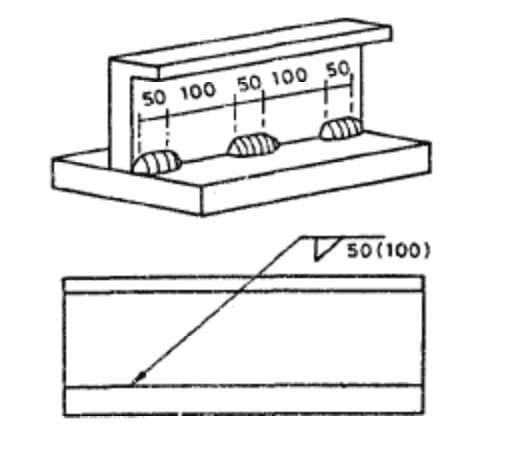

Deck puddle weld symbol

The deck puddle weld symbol is a specific graphical representation used on engineering drawings to indicate the location and specifications of puddle welds in deck construction.

Puddle welds are commonly used to connect steel deck plates or decking to supporting structural members, such as beams or joists. The symbol provides essential information for welders and construction personnel to accurately execute the welds.

The deck puddle weld symbol typically includes the following components:

- Reference Line: The symbol begins with a horizontal reference line, representing the deck plate or the surface where the weld is to be applied.

- Weld Symbol: A small circle or dot is placed at the intersection of the reference line to indicate the location of the deck puddle weld.

- Weld Size: The size or diameter of the puddle weld is indicated by placing a dimension value alongside the weld symbol. This value specifies the desired size of the weld in inches or millimeters.

- Additional Specifications: Additional information about the weld may be included alongside the symbol or in a separate note. This can include details such as the weld process, filler metal, weld quality requirements, or any other specific instructions relevant to the deck puddle weld.

Puddle weld vs Plug weld

Puddle Weld:

- Joining Method: Puddle welds involve creating a small weld deposit or “puddle” at the intersection of two overlapping metal surfaces.

- Application: They are commonly used when access to the backside of the joint is limited or not possible, such as in sheet metal fabrication or when joining structural steel components.

- Weld Formation: Puddle welds are formed by melting the base material and adding filler metal, if necessary, to create a fused joint at the intersection of the overlapping surfaces.

- Joint Strength: Puddle welds provide strength by creating a fusion between the overlapping surfaces, resulting in a secure connection.

- Appearance: Puddle welds may leave a visible weld deposit or “puddle” on the surface, which can be visually noticeable.

Plug Weld:

- Joining Method: Plug welds involve creating a weld at the hole or opening in one of the metal components being joined.

- Application: They are commonly used when two components overlap and require a strong connection, such as in automotive manufacturing, construction, or general metalwork.

- Weld Formation: Plug welds are formed by melting and fusing the base material around the hole or opening in one of the components, effectively joining the two components together.

- Joint Strength: Plug welds offer strength by filling the hole or opening in one of the components, creating a solid connection between them.

- Appearance: Plug welds are typically less visible as the weld is formed within a hole or opening of one of the components, making them more cosmetically appealing than puddle welds.