Soldering is a fundamental process in electronics and metalworking, allowing for the joining of two or more metal components using a molten filler material.

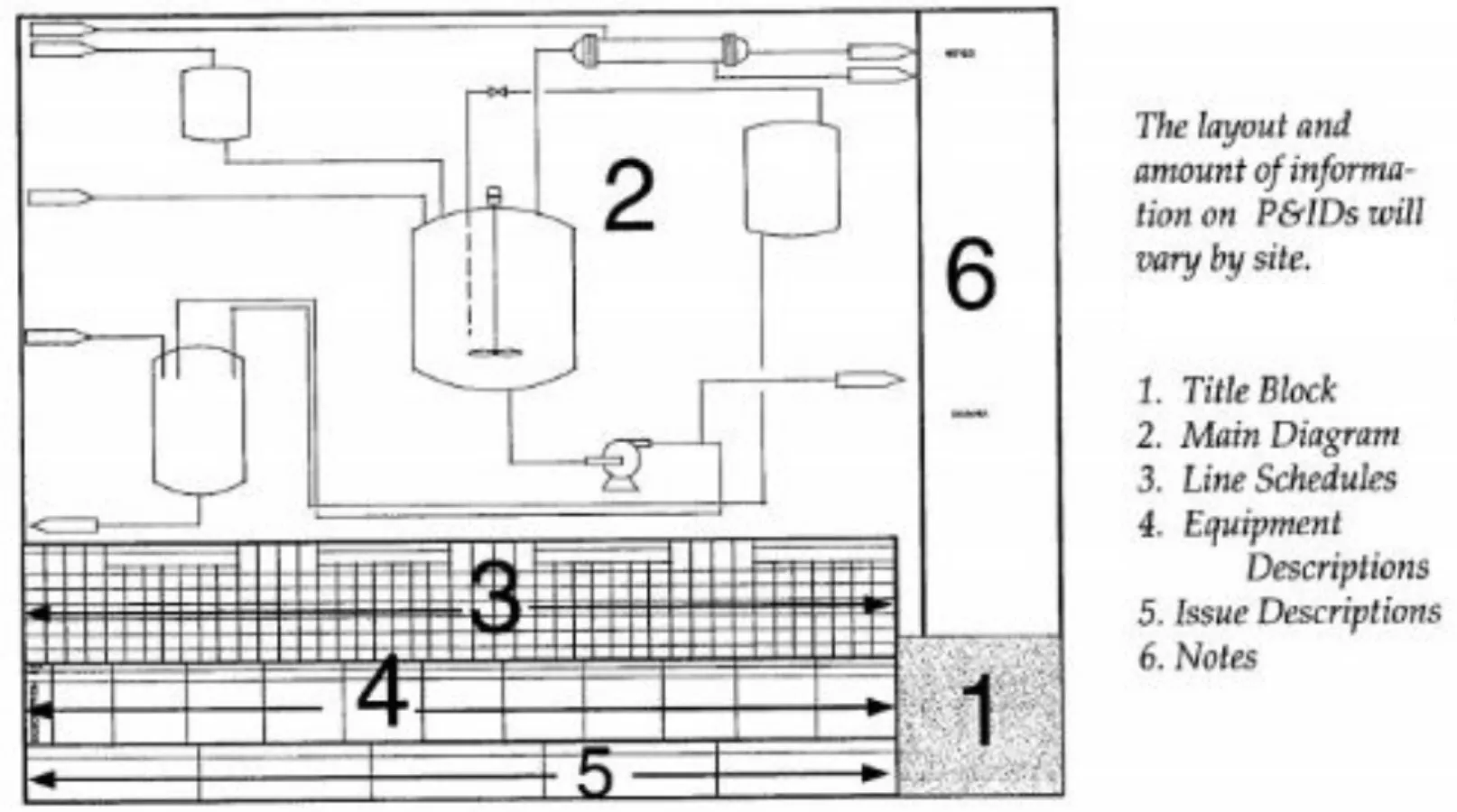

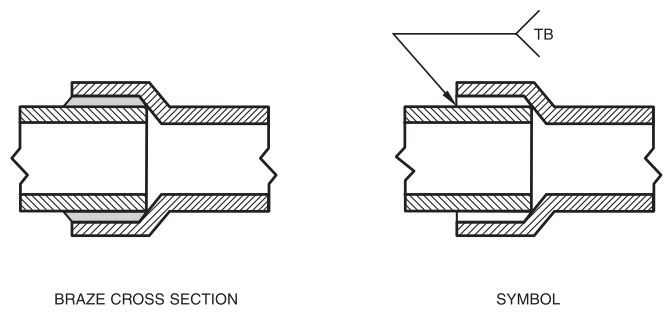

To ensure precision and clarity in communicating soldering requirements, standardized symbols are used in technical drawings and specifications.

These soldering symbols play a crucial role in guiding technicians, engineers, and manufacturers throughout the soldering process.

In this blog post, we will learn the basics of soldering symbols, their meanings, and understand how they facilitate effective soldering operations.

The Importance of Soldering Symbols

Soldering symbols serve as a visual language that enables clear communication and eliminates ambiguity when it comes to soldering requirements.

Just like any other symbols used in technical drawings, soldering symbols convey crucial information about joint types, soldering methods, and additional specifications.

By understanding these symbols, professionals can ensure accurate and consistent soldering results.

Letter Designations for Soldering Processes in Solder Joint Symbol

In solder joint symbols, letter designations are used to represent specific soldering processes or techniques.

These letter designations provide clarity and standardization when indicating the desired soldering method for a particular joint.

Here are some commonly used letter designations for soldering processes in solder joint symbols:

- Dip soldering- DS

- Furnace soldering – FS

- Induction soldering – IS

- Infrared soldering – IRS

- Iron soldering – INS

- Torch soldering – TS

- Ultrasonic soldering – USS

- Wave soldering – WS

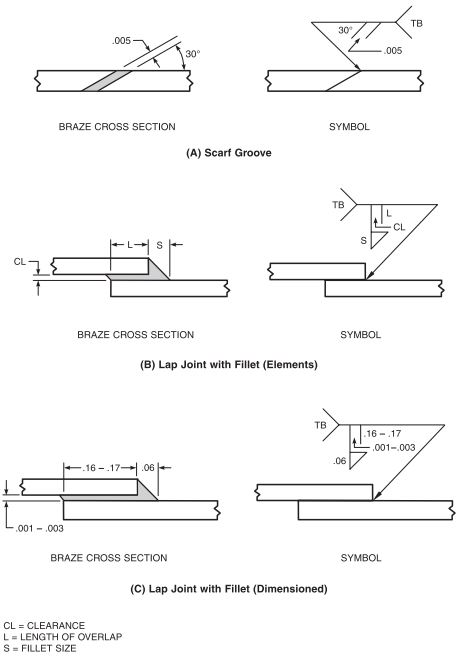

Commonly Used Soldering Joint Symbols

a. Solder Joint Type Symbols:

- Square: Represents a square butt joint.

- Triangle: Denotes a triangular fillet joint.

- Circle: Indicates a circular fillet joint.

- Combination Symbols: Depict composite joint types, such as a square and fillet joint combination.

b. Soldering Method Symbols

- Wave Soldering: Depicted by a series of horizontal lines resembling waves.

- Hand Soldering: Illustrated by a hand-shaped symbol holding a soldering iron.

- Reflow Soldering: Represented by a series of arrows depicting the flow of heat.

c. Additional Soldering Symbols

- Soldering Dimensions: Indicate the required measurements for soldered joints.

- Solder Material Specifications: Specify the type of solder alloy or flux to be used.

- Thermal Management Symbols: Provide information about heat sinks, thermal pads, or other cooling techniques.

Interpreting Soldering Symbols

To effectively interpret soldering symbols, it is essential to familiarize oneself with industry standards and conventions.

A comprehensive understanding of the specific soldering symbol set being used is crucial.

This can be achieved through referencing relevant standards, such as the IPC (Association Connecting Electronics Industries) standards for electronics assembly.

Advantages of Using Soldering Symbols

Employing soldering symbols brings several advantages to the soldering process:

- a. Clarity and Consistency: Soldering symbols ensure that everyone involved in the soldering process understands the requirements precisely, leading to consistent results.

- b. Time and Cost Savings: Clear specifications minimize errors, reducing the need for rework or component replacement.

- c. International Standardization: Soldering symbols follow standardized conventions, enabling seamless communication across borders and language barriers.