Root Opening Weld Symbol

The root opening is a critical parameter that affects the weld quality, strength, and overall performance. It determines the amount of filler metal needed and influences the weld’s ability to withstand mechanical stresses and environmental factors.

When it comes to groove welds, the root opening weld symbol specifies the size of the gap at the root of the joint. This is important because a proper root opening ensures proper fusion and penetration, leading to a stronger and more reliable weld.

Similarly, in flare welds, the root opening weld symbol specifies the desired separation between the flange and the web of the joint. This separation allows for proper fusion and ensures that the weld joint can withstand the required load and stresses.

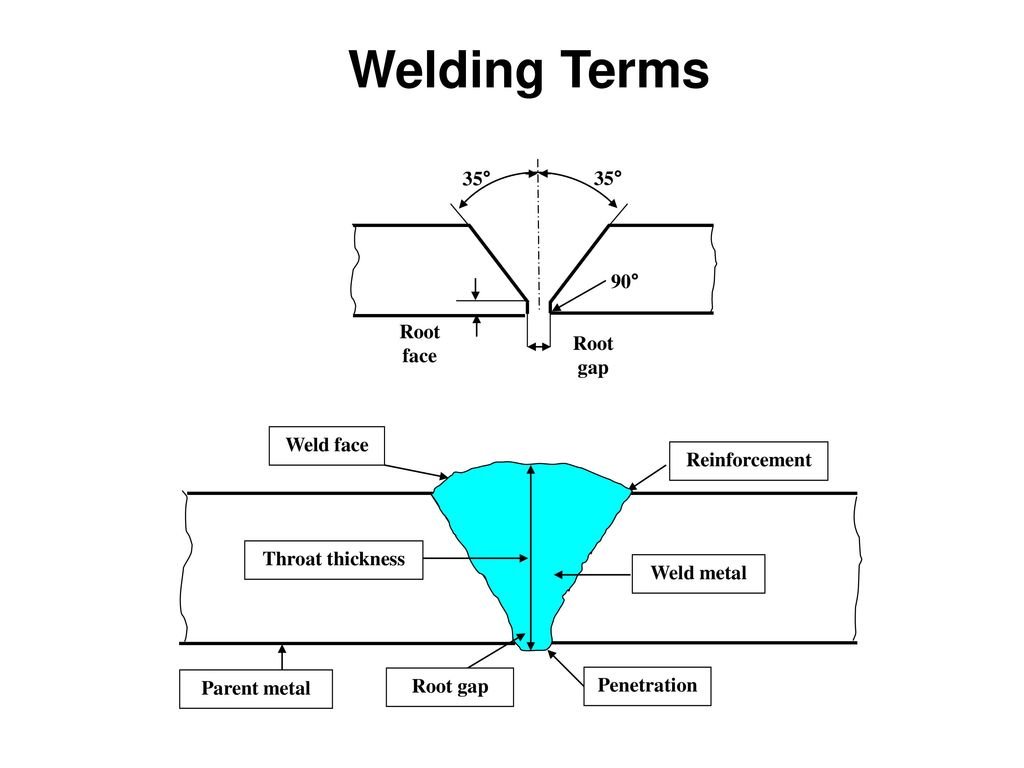

What is Root Opening in Weld?

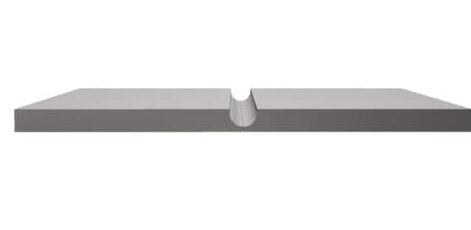

Root opening refers to the separation or gap between the edges of the base metals at the root of a groove or T-joint. It is a critical parameter that influences the weld strength, penetration, and overall quality.

Root opening is also known as root gap. Watch this video to learn about groove and fillet weld complete terminology.

The root opening determines the amount of filler metal required and affects the weld’s ability to withstand mechanical stresses and environmental factors.

Recommended Root Opening for Groove Welds

The recommended root opening for groove welds depends on various factors, such as the base metal thickness, welding process, and joint design.

As a general guideline, the root opening should be approximately 1/16 to 1/8 inch (1.6 to 3.2 mm) for thin materials (up to 1/4 inch or 6.4 mm) and increase proportionally for thicker materials.

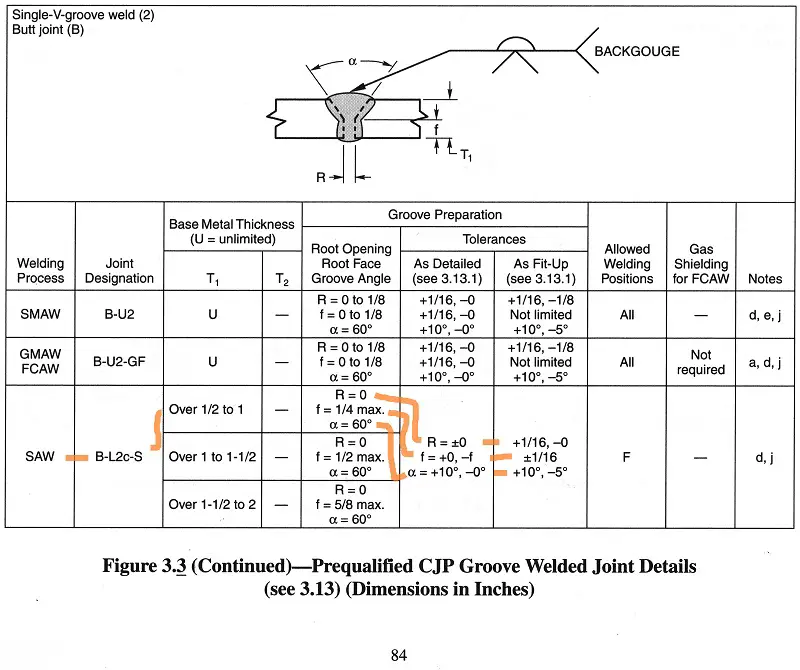

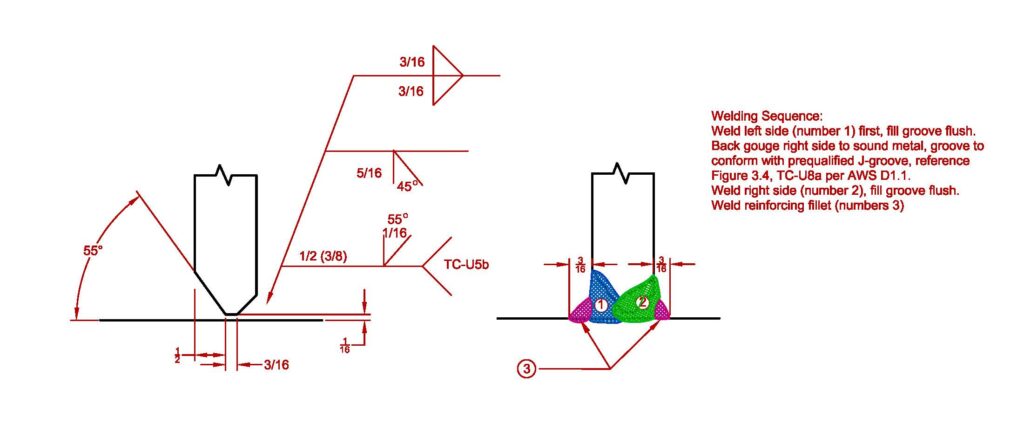

Below is an example of recommended root opening as per AWS D1.1 for V-Groove weld.

However, it is essential to refer to specific welding codes, industry standards, or project requirements for precise root opening recommendations. AWS D1.1 design section as well as EN15085-3 provides sketches with recommended root opening in welds.

Using Welding Symbols to Specify Root Opening

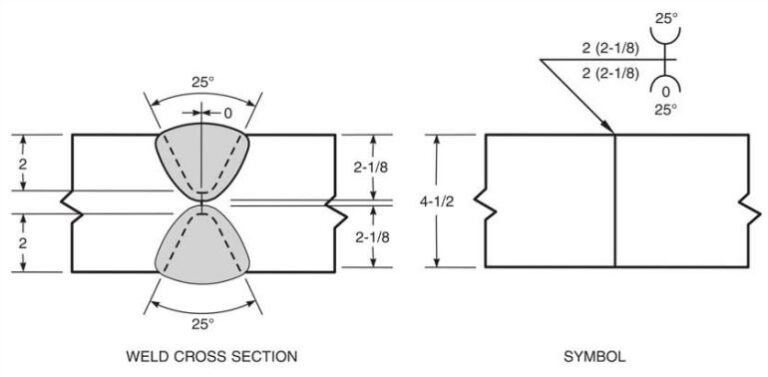

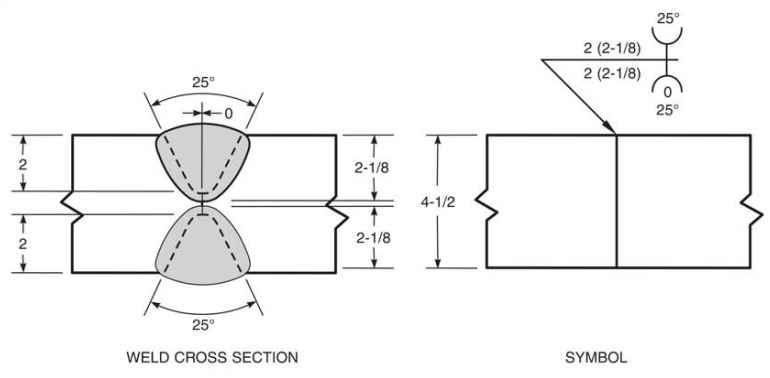

If necessary, a groove weld can include various dimensions such as a groove angle, root opening, groove radius, depth of the groove preparation, and groove weld size.

However, it is important to note that sometimes these dimensions may not be specified at all. In such cases, it is left to the welder’s discretion to determine how the part should be prepared and welded.

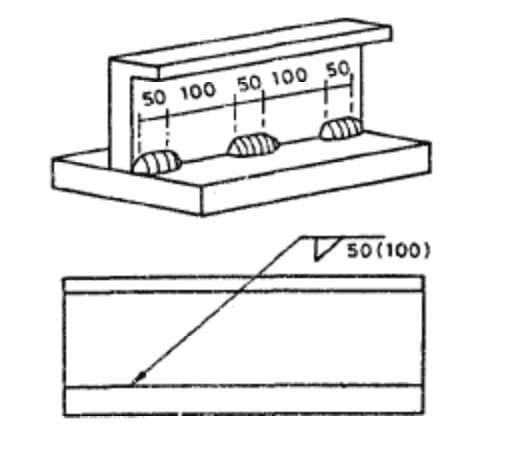

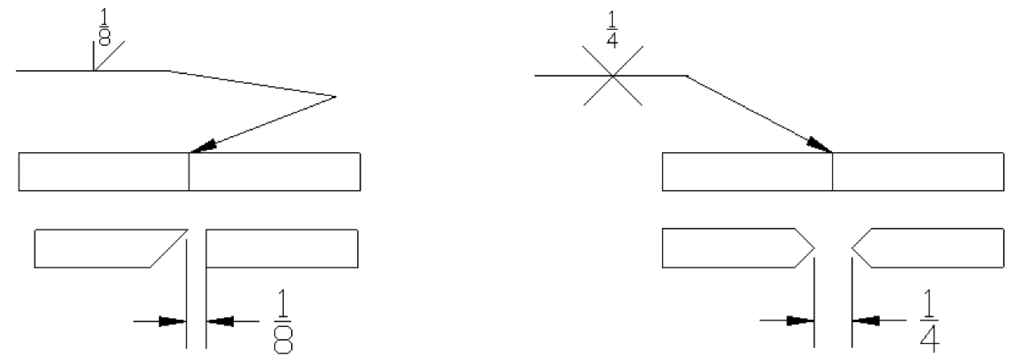

The presence of a root opening is most commonly associated with groove welds. It refers to a predetermined gap between two members that are to be welded together. In this case, Root opening is specified between the main weld symbol as shown in below example.

In this example, root opening in “0” and it is mentioned within the U-groove weld symbol.

While it is not always required, the inclusion of a root opening can be beneficial in ensuring complete penetration or even achieving melt through during the welding process. It is worth mentioning that the root opening dimension can be omitted from the welding symbol if it is not deemed necessary or relevant to the specific welding application.

Recommended Root Opening for T-Joints

In T-joints, the recommended root opening is typically larger than in groove welds. This is because T-joints require more space for proper fusion and penetration. The root opening for T-joints should generally be around 1/8 to 3/16 inch (3.2 to 4.8 mm) for thinner materials, and it may increase as the thickness of the base metal increases.

Benefits of Root Opening

- Improved Weld Penetration: A proper root opening allows for better access to the joint, facilitating complete fusion and penetration. This results in a stronger, more durable weld with enhanced mechanical properties.

- Reduces the Risk of Incomplete Fusion: Insufficient root opening can lead to incomplete fusion, where the filler metal fails to bond adequately with the base metal. By providing sufficient space, the root opening minimizes the risk of incomplete fusion, ensuring a sound and defect-free weld.

- Accommodates Welding Distortions: Welding induces thermal stresses and distortions. A suitable root opening allows for the release of these stresses, reducing the likelihood of deformation and cracking in the completed weld.

Conclusion

The root opening weld symbol plays a significant role in communicating the desired gap between base metal edges in a weld joint. By adhering to recommended root opening values, welders can achieve better weld penetration, reduce the risk of defects, and enhance the strength and quality of the weld.