When it comes to welding, accuracy is paramount. Welding drawings serve as a vital communication tool, conveying explicit instructions to welders about the type and extent of the weld required.

A Full Penetration Weld Symbol is used to specify weld having full penetration or through penetration in the required weld joint.

In this post, I have covered what is a Full Penetration Weld Symbol, what is Full Penetration Weld, its applications and limitations.

What is a Full Penetration Weld?

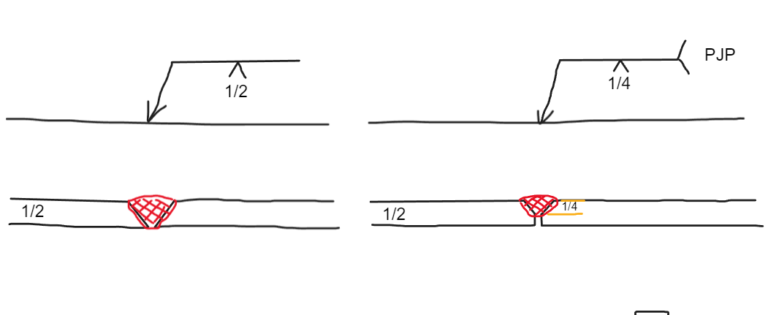

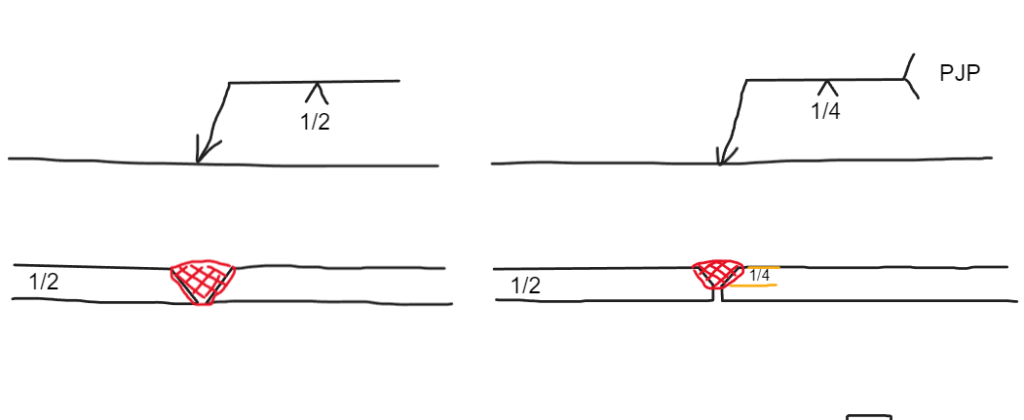

A full penetration weld, also known as complete joint penetration (CJP), is a type of weld that involves filling the entire joint gap with filler material. Unlike partial joint penetration (PJP) welds, which do not reach the root of the joint, full penetration welds penetrate from the toe (top) to the root (bottom) of the joint. These welds are characterized by their high strength and durability.

Understanding the Full Penetration Weld Symbol

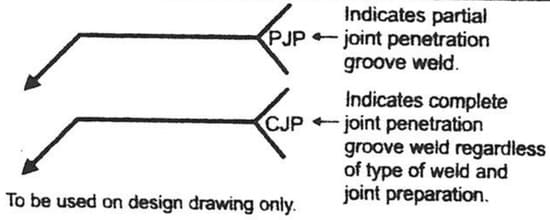

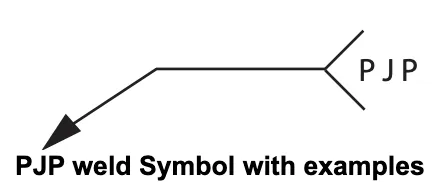

In welding drawings, the full penetration weld is represented by a specific symbol. The symbol consists of a straight line with a triangle attached to it. The triangle indicates the side of the joint where the weld is to be performed.

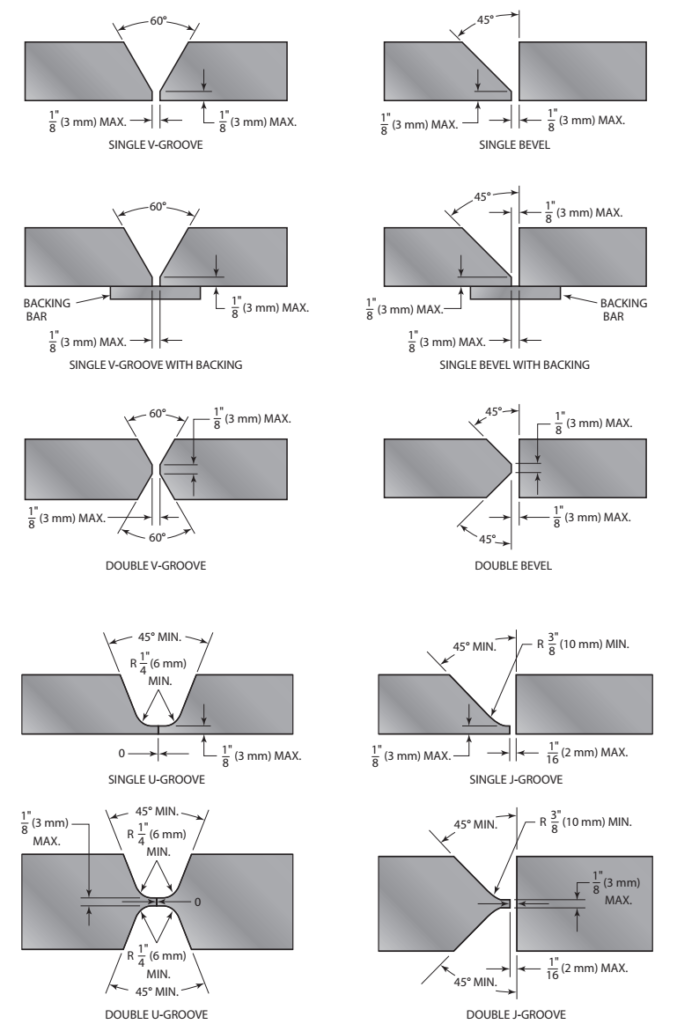

A full penetration weld symbol applied to specific type of welds such as:

- Flare Groove weld,

- V- Groove, U- Groove & J-Groove weld,

- Flare bevel and Flare groove weld,

- Square Groove weld,

- T- joints with bevel.

The symbol is placed on the reference line, which represents the joint to be welded. This representation provides clear instructions to the welder about the type and extent of the weld required.

Significance of the Full Penetration Weld Symbol

The full penetration weld symbol serves as a communication tool between designers, engineers, and welders. It ensures that everyone involved in the welding process understands the specific requirements for achieving a strong and reliable joint. By following the symbol, welders can accurately execute the weld and achieve the desired level of penetration.

Interpreting the Full Penetration Weld Symbol

To interpret the full penetration weld symbol correctly, it is essential to understand its components. The straight line represents the reference line or the joint to be welded. The triangle attached to the line indicates the side of the joint where the weld is to be performed. By analyzing the symbol’s orientation and placement, welders can determine the exact location and extent of the weld.

Tips for Achieving Full Penetration Welds

To achieve a successful full penetration weld, several factors come into play. These include:

- Proper Welder Settings: Adjusting the current and voltage settings according to the welding specifications is crucial for achieving adequate penetration.

- Electrode Selection: Choosing the appropriate electrode composition and diameter is essential to ensure optimal penetration and fusion.

- Polarity: Using the correct polarity, such as DC+ (positive electrode, negative workpiece), enhances penetration by creating a deeper weld pool.

- Travel Angle and Speed: Maintaining a low travel angle (close to perpendicular) and a balanced travel speed ensures sufficient energy delivery and prevents excessive weld pooling or insufficient penetration.

Conclusion

The full penetration weld symbol is a fundamental element in welding drawings that conveys precise instructions for achieving strong and durable joints. By understanding the symbol and implementing the necessary techniques, welders can consistently produce high-quality welds with full penetration. Mastering the art of full penetration welding is crucial for ensuring the structural integrity and longevity of welded components in various industries.