Melt through weld symbol

The melt-through weld symbol is a basic Weld Symbol used in welding to indicate that a weld joint must be fully penetrated from one side with visible root reinforcement. The symbol is typically a semi-circle and is used on engineering drawings and blueprints to communicate the specific requirements for the weld joint to the welder.

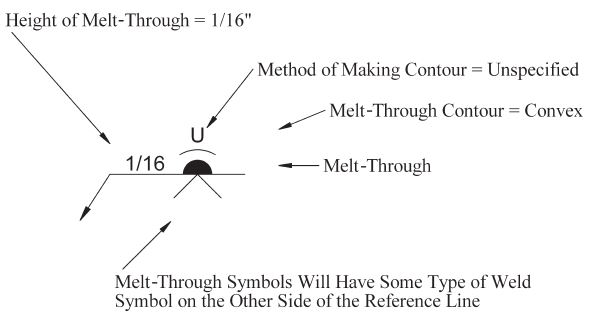

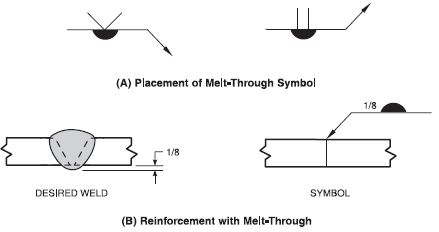

The symbol is usually filled in with a dark color to differentiate it from Back/ Backing weld symbol and placed opposite to the main weld symbol. The height of melt-through or also called weld reinforcement is always specified on the left side (1/16″ in below example). Supplementary contour welding symbol if required can also be specified on the melt-through symbol. You may notice

V Groove Weld with melt through weld symbol

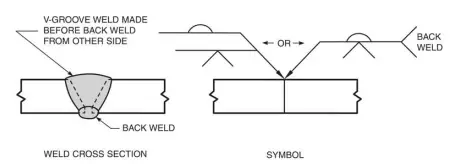

The figure (A) shows a melt through weld symbol for V Groove weld and Square groove weld. used to indicate that a weld must penetrate the full thickness of the joint and have visible reinforcement on the back side.

This melt through symbol consists of a filled-in semi-circle. Unlike an open semi-circle symbol for a back weld, the melt through symbol is solid. As seen in the figure, the melt through symbol is placed on the opposite side of the reference line from the main welding symbol to specify the reinforcement.

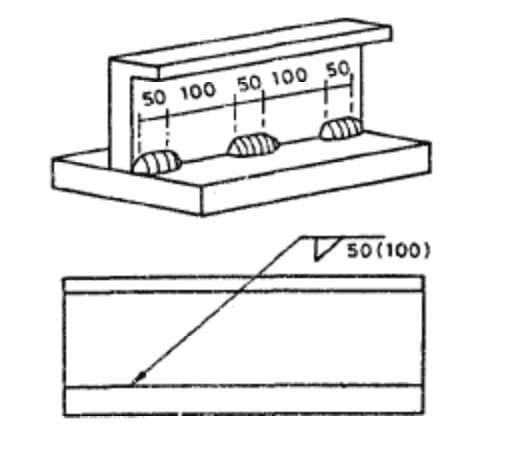

The depth of required melt-through reinforcement is specified always on the left side of the welding symbol as shown in figure B below.

Melt through weld Definition

In a melting through weld, the welder allows the molten metal to penetrate through the entire thickness of the joint, resulting in a complete fusion of the two pieces of metal.

A melt-through weld can have a V-Groove or Square Groove depending upon type of welding process. Advance welding such as plasma keyhole and laser welding can produce square groove weld with melt-thru welds due to their high arc energy arc density.

Melt through weld is often used in applications where a strong, leak-tight joint is required, such as in the construction of pressure vessels or pipelines.

AWS melt thru weld symbol

The American Welding Society (AWS) defines melt-through as the creation of visible reinforcement at the root of a weld joint that has been welded from one side. Essentially, melt-through occurs when the weld metal penetrates the base metal and extends beyond it on the opposite side of the joint.

The melt-through weld symbol may include additional information such as specifications for height, contour, method of contour, and tail. This information is used to provide further details about the specific requirements for the weld joint and is commonly included on engineering drawings and blueprints.

The AWS standard utilizes the melt through symbol to indicate the need for full joint penetration and visible root reinforcement. If the height of the root reinforcement needs to be specified, the required dimension can be placed to the left of the melt through symbol. This allows for the specification of the size of the penetration bead, such as 1/16 inch or 1/8 inch.

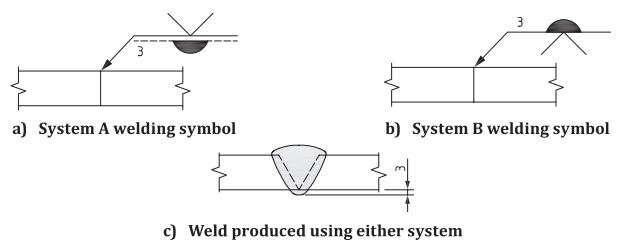

ISO Melt Through Welding Symbol

ISO 2553 melt-through welding symbol is same as AWS A2.4 welding symbol. Melt through weld symbol is called Root reinforcement symbol in ISO 2553 standard and only be used for complete join penetration (CJP Weld) welds with minimum specified root reinforcement (Root welding penetration) made from one side. The placement of symbol can be based on:

- System A: old ISO welding symbol with dashed reference line.

- System B: New system, similar to AWS A2.4.