Corner Weld Symbol

The corner weld symbol is a graphical representation used in welding to indicate the type and location of a corner joint weld. It is commonly used in engineering drawings and welding blueprints to provide clear instructions to welders.

This article provides valuable guidance on What is a Corner Weld, Corner weld different weld types along with their welding symbols.

What is a Corner Weld Symbol?

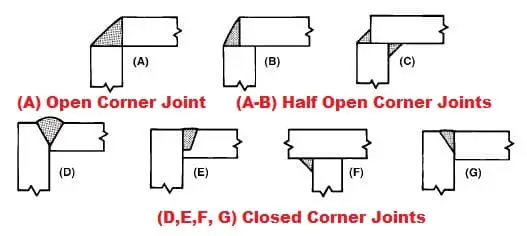

A corner weld is a type of weld used to join two components that meet at a corner or right-angle junction.

Corner welds play a crucial role in structural applications, where they provide strength, rigidity, and stability to components and assemblies. They are commonly found in frameworks, support structures, frames, and various other types of metal fabrications.

What is a Corner Weld Symbol?

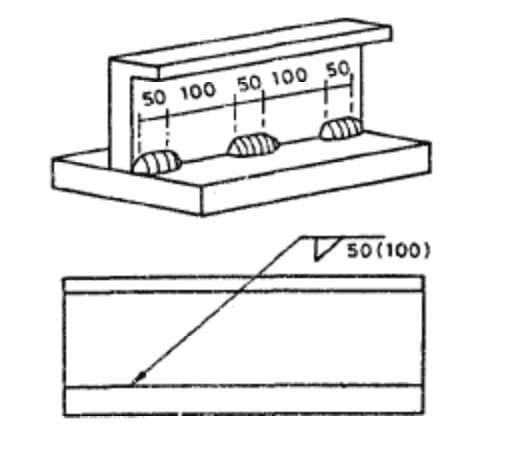

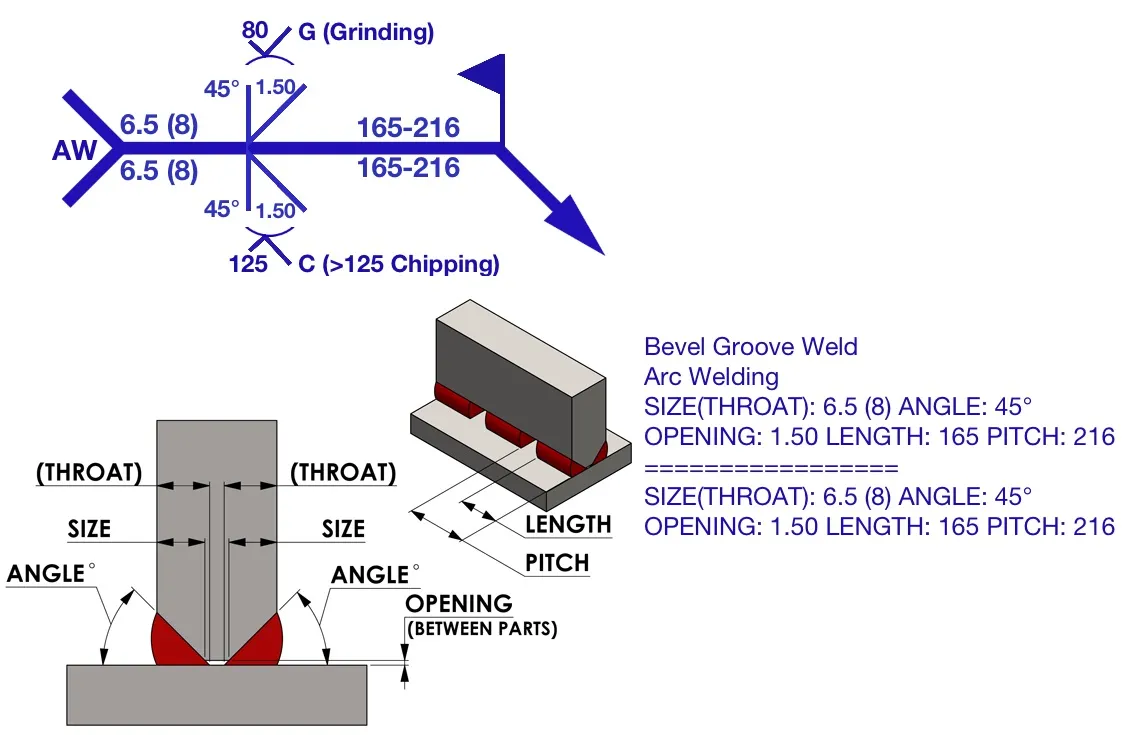

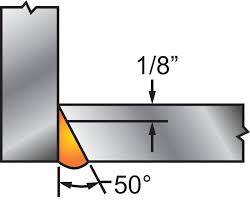

A corner weld symbol is a graphical representation used to indicate the type and dimensions of a weld joint in a corner configuration. The type of Corner Weld symbol depends on the particual type of weld joint such as Fillet weld or bevel weld. Various types of Corner weld and their respective corner welding symbols are:

It provides essential information about the weld size, length, and other specifications required for a particular welding operation. By using this symbol, designers and engineers can effectively communicate their welding requirements to the welders, ensuring consistency and accuracy in the final product.

Components of a Corner Weld Symbol

- Arrow: The arrow in the corner weld symbol points to the location where the weld is to be made. It indicates the side of the joint where the weld is required.

- Weld Symbol: The weld symbol is a small drawing placed on the reference line, representing the specific type of weld required (e.g., fillet or bevel). The symbol may vary depending on the welding process, such as fillet, groove, or plug welds.

- Dimensions: The dimensions associated with the corner weld symbol indicate the size and length of the weld.

- Tail: The tail of the corner weld symbol contains additional information, such as the welding process, electrode type, or any other specific instructions relevant to the weld.

Interpreting a Corner Weld Symbol

To interpret a corner weld symbol correctly, one must understand the various elements and their meanings. Here’s a breakdown of the key aspects:

- Arrow: The arrow points to the side of the joint where the weld is to be applied. It indicates the direction in which the weld should progress.

- Weld Symbol: The weld symbol represents the specific type of weld required. For example, a fillet weld is represented by a triangle, while a groove weld is depicted by a straight line or a series of parallel lines.

- Dimensions: The dimensions associated with the corner weld symbol indicate the size and length of the weld. These dimensions are typically expressed in terms of length, width, or both.

- Tail: The tail of the corner weld symbol provides additional information related to the welding process, electrode type, or any specific instructions relevant to the weld. It ensures that welders have all the necessary details to perform the weld accurately.

Significance of the Corner Weld Symbol

The corner weld symbol serves as a vital communication tool between designers, engineers, and welders. Its significance lies in the following aspects:

- Clarity and Consistency: By using standardized symbols, the corner weld symbol ensures clear and consistent communication of welding requirements. It eliminates ambiguity and reduces the chances of misinterpretation, leading to improved welding quality.

- Time and Cost Efficiency: With accurate information provided by the corner weld symbol, welders can perform their tasks efficiently, reducing the need for rework or modifications. This saves both time and costs associated with welding operations.

- Compliance with Standards: The corner weld symbol adheres to industry standards, such as those set by the American Welding Society (AWS) or the International Organization for Standardization (ISO). Compliance with these standards ensures that welding operations meet the required quality and safety criteria.

Conclusion

The corner weld symbol is a crucial element in welding operations, enabling effective communication between designers, engineers, and welders. By understanding its components and interpreting its meaning correctly, professionals in the welding industry can ensure accurate and consistent welds. The use of standardized symbols, such as the corner weld symbol, enhances efficiency, reduces errors, and ultimately contributes to the overall quality of welded products.

Reference: