Welding symbols are a universal language used by welders, engineers, and designers to communicate welding requirements effectively. They provide crucial information about joint design, welding processes, and other essential details necessary for successful welding operations. Among the various welding symbols, the U-Groove symbol holds particular importance due to its versatility and widespread use in different industries.

In this article, we will break down What is a U-Groove, U-Groove welding symbol, U-Groove types and their symbols, and V-Groove vs U-Groove weld. We will also discuss the advantages and limitations of U-Groove welds, along with practical tips for interpreting and implementing these symbols correctly.

What is a U-Groove Weld?

U-Groove welding is a type of groove welding where the piece of metal to be welded has a ‘U’ shape groove. This technique is typically used in situations where the metal pieces are thicker, and a complete penetration weld is required, enhancing the joint’s strength. The ‘U’ shape of the groove allows for better control of the weld pool, resulting in a cleaner, more robust weld.

Types of U-Groove Welding

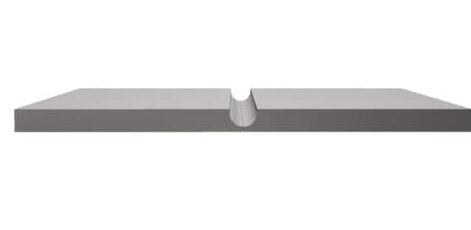

There are two primary types of U-Groove welding, based on the number of grooves involved in the process:

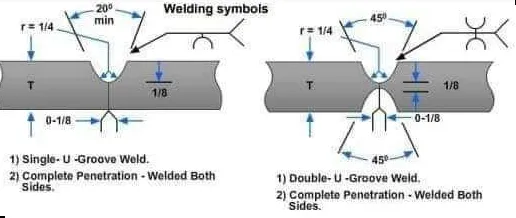

- Single U-Groove Welding: This type involves a single ‘U’ shaped groove on one side of the joint. A filler metal is then used to join the pieces together. This is generally used when one side of the weld is accessible.

- Double U-Groove Welding: This process involves a ‘U’ shaped groove on both sides of the joint. The double U-groove weld is used when both sides of the weld are accessible and offers a higher joint strength due to the greater weld area.

U-Groove Welding Symbols

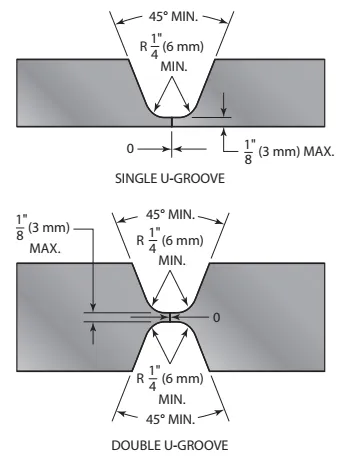

Understanding welding symbols is critical for communicating design intentions. The American Welding Society (AWS) provides the standard symbols used in welding documentation.

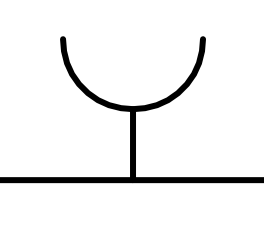

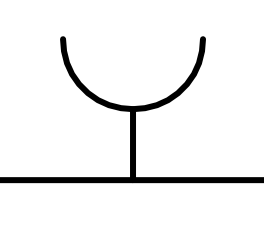

A U-groove weld symbol appears as a half-circle (U shape) placed at the reference line. Furthermore, the symbol’s placement – above or below the reference line – signifies if the weld is on the arrow side or the other side of the joint.

Single U-Groove Welding Symbol

The single U-groove welding symbol appears as a half-circle (U-Shape) on the reference line’s side where the weld will be made. The symbol’s orientation (opening upward or downward) doesn’t change the meaning.

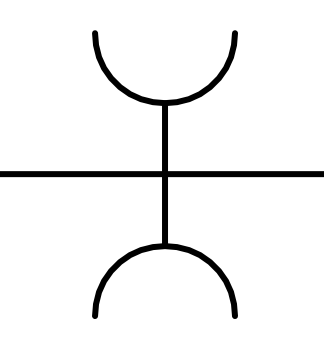

Double U-Groove Welding Symbol

The double U-groove welding symbol consists of two half-circle (U-Shape) symbols, one above and one below the reference line, indicating U-grooves on both sides of the joint.

U-Groove Welding Symbol Examples

In a typical welding drawing, you may encounter the U-groove symbol with additional elements, such as a depth of groove, groove angle, or root opening information. These specifications are usually numerically indicated and placed within or near the U-groove symbol.

V-Groove vs U-Groove

The choice between V-groove and U-groove welding often boils down to the specific application, the material thickness, and the desired strength and quality of the weld.

- V-Groove: Suitable for thinner metals, V-groove welding is simpler and faster but may not provide as strong a weld as U-groove welding.

- U-Groove: Ideal for thicker materials, U-groove welding offers a more substantial joint due to the larger weld area. However, it requires more time and precision, making it a more costly process.

In conclusion, U-groove welding plays a vital role in creating strong, high-quality welds for thicker materials. Understanding its symbols and how it compares to V-groove welding is essential for anyone involved in the welding industry. With the right knowledge, these symbols become clear instructions, paving the way for successful and efficient welding projects.