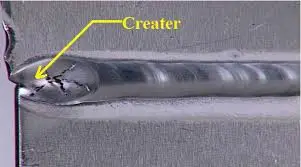

What is a Toe Crack in Welding?

A toe crack in welding refers to a specific type of welding defect that can occur at the junction between the face of the weld and the base metal.

It is characterized by a crack that forms at the toe, which is the point where the weld transitions into the base metal.

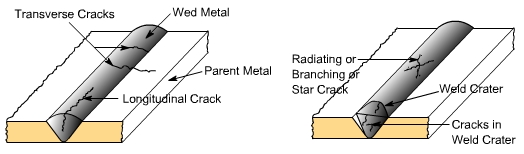

Types of Cracks in Weld Metal

Heat-Affected Zone (HAZ) Cracks in welding

These cracks form in the heat-affected zone adjacent to the weld. They can occur due to the rapid heating and cooling during the welding process, leading to a brittle microstructure and susceptibility to cracking.

Transverse Cracks in welding

Transverse cracks are perpendicular to the direction of the weld. They can result from high levels of tensile stress or inadequate fusion between the weld metal and base metal.

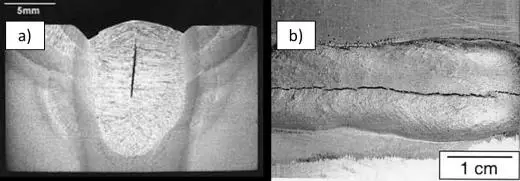

Longitudinal Cracks in welding

Longitudinal cracks run parallel to the weld axis. They can be caused by excessive shrinkage stresses, inadequate joint preparation, or improper welding techniques.

Centerline Cracks in welding

Centerline cracks occur along the centerline of the weld. They can be attributed to factors such as high hydrogen content in the weld metal, improper preheating, or insufficient heat input.

Undercut Cracks in welding

Undercut cracks form in the groove or notch at the edge of the weld. They are typically caused by excessive heat input or improper welding technique, resulting in a depressed area that is prone to cracking.

Hot Cracks in welding

Hot cracks, also known as solidification cracks, occur during the cooling phase of the weld. They are caused by the formation of low-melting-point phases or the presence of impurities in the weld metal.

Cold Cracks in welding

Cold cracks, also referred to as delayed cracks, can appear after the completion of the welding process. They are typically caused by hydrogen embrittlement, stress relief cracking, or residual stresses in the weld.

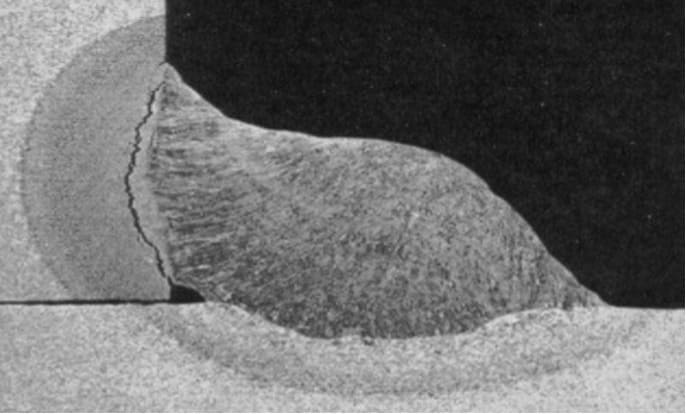

Lamellar Tearing in welding

Lamellar tearing is a type of crack that occurs in the base metal, parallel to the weld. It happens due to the presence of high tensile stresses perpendicular to the plate surface, combined with the presence of a susceptible microstructure.

Radial or Stress Crack in welding

This type of crack occurs due to high levels of stress in the weld area. It can develop radially from the center of the weld or propagate along the length of the weld. Stress cracks are often caused by factors such as improper welding techniques, excessive heat input, or inadequate joint preparation.

Under-Bead Crack in welding

Under-bead cracks extend through the hardened zone below the fusion line. They can result from factors such as rapid cooling of the weld, improper heat treatment, or the presence of hydrogen in the weld metal.

Causes of Welding Cracks

Toe cracks in welding can occur due to several reasons, including:

- High Stress Levels: Excessive stress in the weld area, often caused by incorrect welding techniques, improper welding parameters, or poor joint design, can lead to the formation of toe cracks.

- Metallurgical Factors: Cracks can also result from metallurgical defects in the base metal or filler metal. This includes issues such as corrosion, impurities, or improper heat treatment of the materials.

Prevention of Toe Cracks in Welding

To prevent toe cracks in welding, several measures can be taken. Here are some preventive steps:

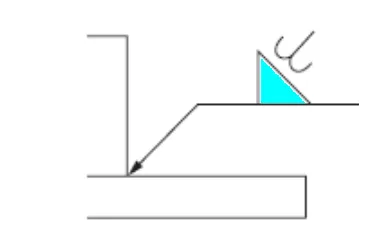

Proper Joint Preparation

Ensure that the joint edges are clean, free from contaminants, and properly prepared before welding. This includes removing any rust, scale, or paint that can affect the quality of the weld.

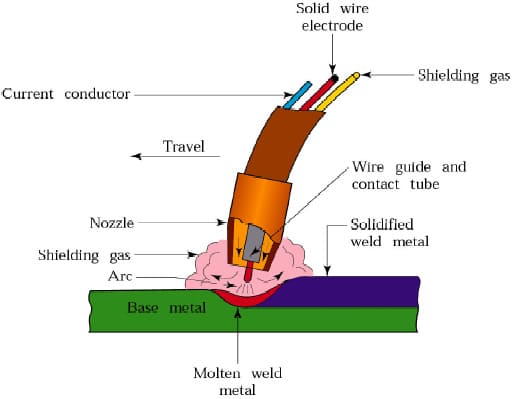

Control Heat Input

Use proper welding parameters, such as appropriate current, voltage, and travel speed, to control the heat input during welding. Excessive heat can increase the risk of toe cracks, so it’s important to maintain the optimal temperature range for the specific material being welded.

Correct Welding Technique

Adhere to proper welding techniques, including maintaining the correct angle, travel speed, and electrode positioning. Improper technique can lead to inadequate fusion or excessive stress concentration at the weld toe, increasing the likelihood of cracks.

Preheat and Post-Weld Heat Treatment

Preheating the base metal before welding can help reduce the cooling rate and minimize the risk of thermal stresses that can contribute to toe cracks. Additionally, post-weld heat treatment, such as stress relieving, can help alleviate residual stresses and improve the overall integrity of the weld.

Select Suitable Welding Consumables

Choose welding consumables, such as electrodes or filler wires, that are appropriate for the specific material being welded. Using the correct consumables can ensure proper fusion, reduce the risk of brittle microstructures, and improve the weld’s resistance to cracking.

Control Welding Sequence

Plan the welding sequence to distribute the heat evenly and minimize thermal gradients. Avoid excessive welding in a localized area, as it can lead to rapid cooling and increased stress concentration at the weld toe.

Monitor Hydrogen Content

Hydrogen can contribute to cracking, so it’s important to control the hydrogen content in the weld metal. Use low-hydrogen electrodes or take precautions to minimize moisture absorption during welding, such as keeping the electrodes dry and using proper storage techniques.