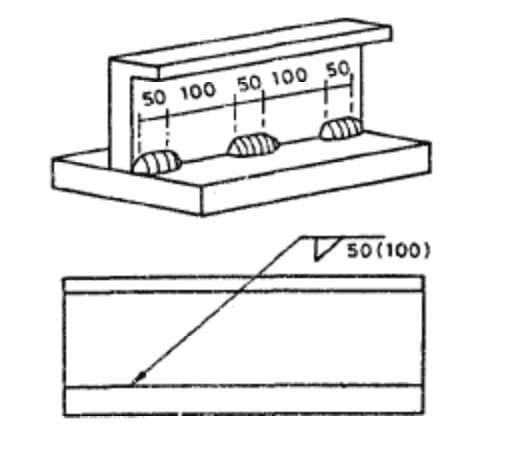

Stitch welding is a welding technique used to join two or more pieces of metal together intermittently, rather than continuously. It involves creating a series of short welds or “stitches” along the joint, with small gaps in between each weld. This method is commonly used when a continuous weld is not necessary or desired, such as in situations where heat distortion needs to be minimized or when welding thin materials.

The stitch welding symbol is a graphical representation used in welding blueprints and drawings to indicate the use of stitch welding. In this article, we will delve into the details of the stitch welding symbol, its components, and its significance in the welding industry.

What is Stitch Welding?

Stitch welding is a welding technique commonly used in metal fabrication and repair work. It involves making a series of intermittent welds, or “stitches,” along a joint or seam, rather than welding continuously along the entire length.

The purpose of stitch welding is to minimize heat distortion and prevent warping of the metal, especially when working with thin or delicate materials. By welding in short sections, the heat input is limited, reducing the risk of overheating and distortion.

Stitch welding is often employed in situations where a full-length weld is not necessary or practical. It is commonly used for tack welding or temporarily holding components together before final welding, as well as for making repairs or filling gaps in metal structures.

Understanding the Stitch Welding Symbol

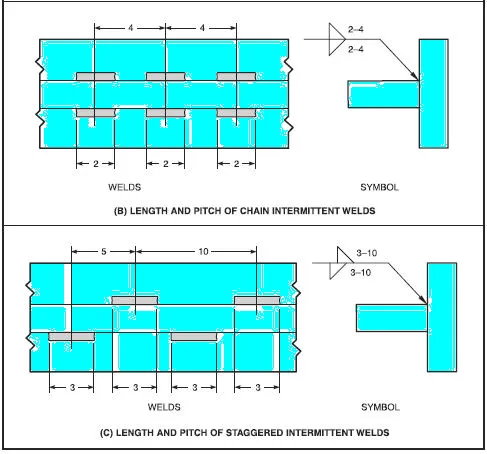

The stitch welding symbol is a graphical representation used on engineering drawings to specify the stitch weld pattern required for a particular joint. It consists of several elements that convey essential information to the welder.

Let’s break down the components of the stitch welding symbol:

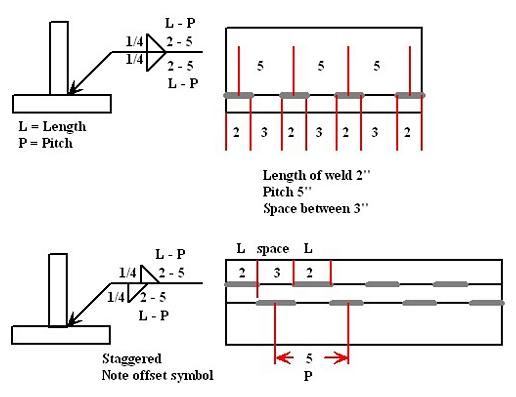

- Arrow: The stitch welding symbol begins with an arrow, which points to the location where the stitch welds are to be applied. The arrow’s tail is connected to the reference line, indicating the joint to be welded.

- Stitch Length: A number is placed above the reference line, indicating the desired stitch length in millimeters or inches. This value represents the distance between each individual weld in the stitch pattern.

- Stitch Spacing (Pitch): Another number is placed below the reference line, indicating the desired stitch spacing. This value represents the distance between the centers of adjacent stitch welds.

- Stitch Welding Symbol: The stitch welding symbol refers to the type of weld such as Fillet weld or groove weld. A basic weld symbol representing the weld type is placed on the reference line.

Related Topic: Intermittent Fillet Weld Symbols: All types explained

Interpreting the Stitch Welding Symbol

To interpret the stitch welding symbol correctly, welders must understand the specific requirements it conveys.

Here are a few key points to consider:

- Stitch Length and Spacing (L): The numbers above and below the reference line indicate the desired stitch length and spacing, respectively. Welders must ensure that each stitch weld matches these specifications.

- Number of Stitches: The number of stitch welds required is not explicitly mentioned in the symbol. Welders should consult the welding procedure specification (WPS) or the engineer responsible for the design to determine the exact number of stitches needed.

Stitch welding standards

Stitch welding, also known as intermittent welding, is a welding technique where a series of short welds are made along the joint instead of a continuous weld. This technique is commonly used in various industries, including automotive, construction, and manufacturing. While there are no specific standards dedicated solely to stitch welding, the following general welding standards and guidelines can be applied:

- American Welding Society (AWS) Standards: AWS provides a range of standards related to welding processes, procedures, and qualifications. Some relevant standards include AWS D1.1/D1.1M for structural welding, AWS D1.6/D1.6M for stainless steel welding, and AWS D1.2/D1.2M for aluminum welding. These standards cover various aspects of welding, including stitch welding.

- International Organization for Standardization (ISO): ISO develops international standards for various industries, including welding. ISO 3834 provides guidelines for quality requirements in welding, including stitch welding. ISO 9606 specifies qualification testing for welders, which can be relevant for stitch welding procedures.

Conclusion

The stitch welding symbol is a valuable tool for welders, enabling them to accurately interpret and execute stitch welds as per design requirements. By understanding the components of the symbol and their significance, welders can ensure the integrity and quality of the welded joints.

Remember, proper interpretation of welding symbols is crucial for achieving the desired results and maintaining safety standards. So, the next time you come across a stitch welding symbol on an engineering drawing, you’ll be well-equipped to tackle the task at hand.