Resistance Spot Welding (RSW) is a widely used welding process in various industries, known for its efficiency, speed, and reliability. To ensure clear communication and understanding between welding professionals, engineers, and inspectors, standardized symbols are used to represent welding operations on technical drawings.

In this blog post, I have covered what is RSW weld, RSW welding symbol, its components, and its significance in the world of welding.

RSW Welding Symbol

The RSW (Resistance Spot Welding) welding symbol is used to represent resistance spot welds on technical drawings and blueprints. It provides essential information about the welding process, such as the location, size, and other specifications of the spot welds.

IF YOU NOTICE BELOW INFO ABOUT RSW WELDING SYMBOL ON ANY OTHER WEBSITE-THIS IS WRONG INFORMATION:

The absence of arrows or other lateral implications in resistance spot weld symbols does not inherently carry any meaning, although additional symbols used alongside them may possess such implications.

Like other welding symbols, RSW welding symbol also has arrow side and other side significance. However if you wish to eliminate this, there is way to do so. How, it is explained in this article.

What is RSW Welding Symbol?

The RSW welding symbol is a graphical representation used on engineering drawings to indicate the specific requirements and characteristics of a Resistance spot weld. It provides essential information about the weld size, location, and other important parameters necessary for the welding process.

Significance of Arrow-Side and Other-Side Members

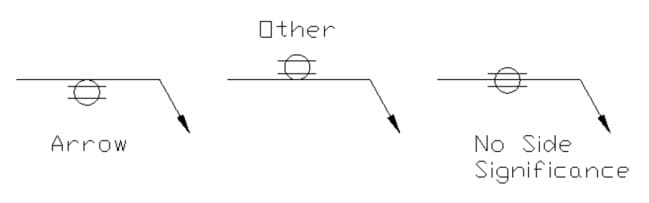

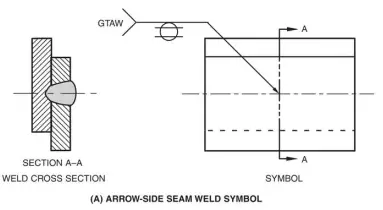

The meaning of the seam weld symbol in relation to its position on the reference line may or may not include arrow-side or other-side member significance. Refer following details explaining arrow side and other side RSW welding symbols.

Arrow-Side Member

When arrow-side member significance is applicable in welding processes, the seam weld symbol should be placed below the reference line with the arrow pointing to this specific member. Refer to Figure below for visual representation.

Other-Side Member

In welding processes where other-side significance is applicable, the other-side member should be indicated by placing the seam weld symbol above the reference line. See Figure above for illustration.

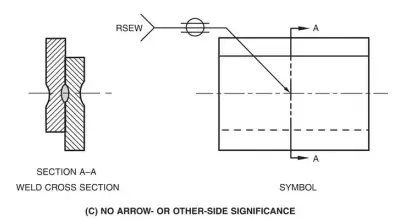

No Side Significance

For welding processes without arrow-side or other-side significance, the seam weld symbol should be centered on the reference line. See Figure above.

Location of Dimensions

Dimensions should be displayed on the same side of the reference line as the weld symbol. If the seam weld symbol does not have arrow-side or other-side significance, all dimensions can be shown on either side. Refer to Figure (A) and (C) for clarity.

Welding Process Reference

The welding process reference should be indicated in the tail of the welding symbol.

RSW Seam Weld length

Seam weld length if required is to be specified on the right side of the RSW weld symbol on the reference line.

Seam Weld Size and Strength

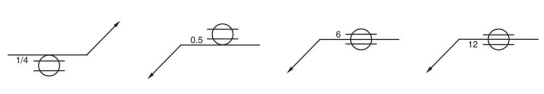

Seam welds can be specified by either their size (weld width) or strength.

Size

To specify seam welds by size, the dimension (weld width) should be indicated to the left of the seam weld symbol. See Figure below for examples.

Left to right:

- Arrow side RSW Weld with 1/4 size,

- Other side RSW weld with 0.5 size

- No side significance RSW weld with 6 & 12 size.

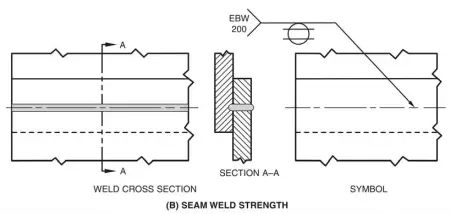

Strength

Alternatively, seam welds can be specified by strength (force) by including a note in the tail of the symbol. Refer to Figure below for visual reference.

In summary, understanding the significance of arrow-side, other-side members, dimension location, welding process reference, and the choice between specifying seam welds by size or strength is crucial for accurately interpreting and communicating welding requirements. Compliance with these guidelines ensures clarity and consistency in the welding process.

Intermittent RSW Seam Weld Symbol

The intermittent RSW (Resistance Spot Welding) seam weld symbol is used to represent intermittent spot welds on technical drawings and blueprints. It provides essential information about the welding process, such as the location, pitch, and orientation of the intermittent spot welds.

Dimensions of Intermittent Seam Welds

Pitch Specification

The distance between the centers of the weld segments, known as the pitch, shall be explicitly specified for intermittent seam welds.

Location of Pitch Dimension

The pitch dimension for intermittent seam welds should be indicated to the right of the length dimension, following a hyphen.

Number of Seam Welds

When a specific number of seam welds is required in a joint, it should be indicated in parentheses on the same side of the reference line as the weld symbol. The number can be positioned either above or below the weld symbol, depending on the appropriate location.

Seam Weld Orientation

Intermittent Welds

By default, intermittent seam welds are interpreted as having their length and pitch measured parallel to the weld axis.

Specification of Orientation

If the seam weld orientation deviates from the default position described in below, a detailed drawing should be provided to clearly indicate the desired weld orientation.

Seam Weld Contour and Finish

Seam welds that require a contour or a specific finish, such as being flush or convex.

Multiple-Member Seam Welds

In cases where one or more members are present between the two outer members in a seam welded joint, the seam weld symbol for the two outer members should be used.

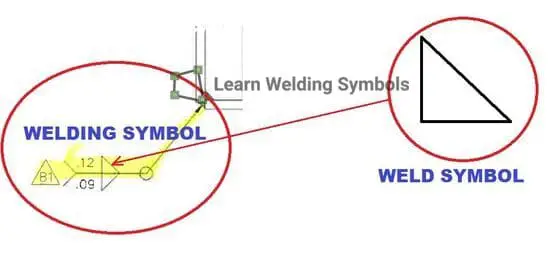

Components of RSW Welding Symbol

- Weld Symbol: The weld symbol in RSW consists of a circle or a series of circles representing the spot weld locations. The number inside the circle indicates the number of spot welds required.

- Size: The size of the weld is typically specified adjacent to the weld symbol. It can be represented by a diameter dimension, indicating the required size of the spot weld.

- Pitch: The pitch represents the distance between individual spot welds when multiple welds are specified. It is indicated by a linear dimension placed below the weld symbol.

- Other Symbols: Additional symbols may be included to convey specific information related to the weld, such as the length of weld, weld sequence, or weld spacing.

Significance of RSW Welding Symbol

The RSW welding symbol serves several important purposes in the welding process:

- Communication: The welding symbol provides a standardized and concise means of communication between designers, engineers, and welders. It ensures that everyone involved in the manufacturing process understands the welding requirements.

- Quality Control: By specifying the size, pitch, and other parameters, the RSW welding symbol helps maintain consistency and quality across welds. Inspectors can refer to the symbol to verify that the welds meet the specified criteria.

- Efficiency: The RSW welding symbol eliminates the need for lengthy written instructions by condensing the welding requirements into a single graphical representation. This saves time and reduces the chances of misinterpretation.

- Compliance: The use of standardized symbols, including the RSW welding symbol, ensures compliance with industry standards and codes. It helps achieve consistency in welding practices and facilitates adherence to safety and performance guidelines.