What is Root Opening in Welding?

Root opening or also called Root Gap refers to the intentional gap or spacing between the members to be joined in order to achieve 100% penetration in groove-type welds.

It is a specified dimension determined by the welding engineer, taking into account factors such as material thickness, plate width, welding process, and other considerations.

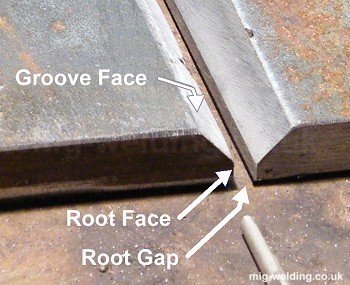

It is essential to differentiate the root opening from the root face, which refers to the beveled edge of the plate meeting at the bottom of the groove.

The Importance of Root Opening

The root opening plays a critical role in welding as it enables the welding torch or electrode to access the root of the weld joint.

This ensures that the weld penetrates fully through the thickness of the material, contributing to the strength and integrity of the joint.

Impact of Incorrect Root Opening Size

It is crucial to maintain the appropriate size of the root opening, as deviations can lead to significant issues:

- Insufficient root opening:

- Incomplete penetration: A small root opening hinders proper weld penetration, resulting in a weaker joint.

- Excessive root opening:

- Defects: A large root opening increases the risk of slag inclusions and other welding defects, compromising the quality of the weld joint.

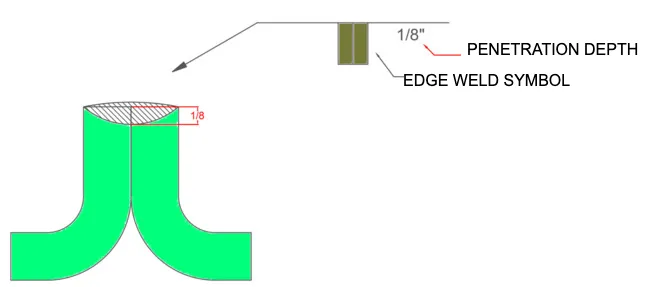

Measuring Root Opening

The welding engineer specifies the desired root opening size, considering factors such as material thickness, plate width, welding process, and more.

In most cases, the root opening is created by machining a groove into the plates to be joined. The edges of the groove are typically beveled at an angle to form the root face, which aids in achieving proper penetration.

The bevel angle usually ranges between 30 and 45 degrees, but it may vary based on the material thickness and other considerations.

Alternatively, certain welding techniques, such as electron beam welding, create the root opening without the need for grooving. In such cases, the focused beam of electrons melts the material, forming the necessary gap for welding.

Controlling Root Opening

Careful control of the root opening is necessary to ensure high-quality weld joints. Welders must adhere to the specified dimensions and follow welding procedures meticulously.

Attention to detail during groove preparation, including groove machining and beveling, is crucial for achieving the desired root opening.

Open and Closed Root in Welding

In welding, the choice between an open or closed root joint depends on the specific requirements and service conditions of the weld joint. This article explores the differences between open and closed roots, their applications, and factors that influence their selection.

Open Root Joint

An open root joint refers to a weld joint with a predefined gap or space between the adjacent members. This type of joint is commonly used for complete penetration joints, where the welding extends through the full thickness of the welded members.

It allows for proper bonding and penetration between the surfaces. In some cases, the open root also facilitates welding the backside of the joint from the front side, which is beneficial for high-pressure or high-strength joints, such as in pipe welding.

Closed Root Joint

A closed root joint occurs when the adjacent members touch each other with no gap or space between them. It is commonly used when complete welding through the full thickness of the material is not required.

Partial penetration or full penetration welds can utilize closed root joints. For full penetration welds with closed roots, it is necessary to chip, grind, or gouge out the unwelded section from the opposite side prior to welding.

Factors Influencing the Choice of Root Joint

Several factors influence the decision to use an open or closed root joint in welding:

Base Metal Thickness

Thinner materials typically cannot accommodate a large root opening, making closed root joints more suitable. Thicker metals may benefit from open root joints as they aid in increasing penetration.

Welding Position

The welding position also plays a role in determining the type of root opening. In flat positions, the liquid from the weld puddle may drop through and cause issues, favoring closed root joints. However, for pipe welding in positions such as 5G, where the pipe runs in a fixed horizontal position, an open root joint may be necessary.

Backing Bar Usage

When a backing bar is used to support the weld joint, an open root joint is typically employed. The backing bar spans the back of the weld joint and is often left in place after welding the open root joint.

Material Compatibility

The type of material being welded can also influence the choice of root joint. Some materials do not work well with open root joints in full penetration welds, especially those that exhibit hot shortness or a loss of strength at high temperatures. In contrast, materials like aluminum often work well with closed root joints for full penetration welding.

Factors Influencing the Choice of Root in Fillet Weld Joint

When it comes to selecting the appropriate root joint for welding applications, several factors come into play. It is crucial to consider these factors to ensure the success and integrity of the welded joint.

Economic Viability and Application Suitability

The first factor to consider is the economic viability and suitability of the joint for the intended application.

Fillet welds have proven to be cost-effective alternatives to other types of welded joints or mechanical fastening methods in various applications. However, it is important to recognize that fillet welds come with their own set of challenges and risks.

Challenges and Risks Associated with Fillet Welds

Fillet welds, despite their advantages, present unique challenges and risks. One crucial consideration is the root gap, also known as the root opening in welding terminology.

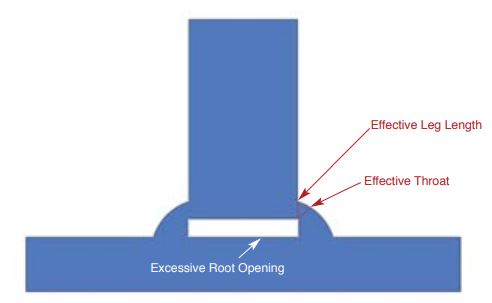

The size of the root opening can significantly impact the weld performance. Excessive root opening can lead to reduced strength and accelerated degradation during service. This occurs due to a reduction of metal at critical failure planes in the fillet weld.

The two most common failure planes in the fillet weld are the effective throat and leg length. A reduced area at these planes means there is less fillet weld metal available to transmit loads and load cycles between the connected members. The weaker plane depends on the joint geometry and the strength of the base metal versus the weld metal.

On the other extreme, the absence of root opening when welding begins can lead to solidification cracking, also known as weld metal hot cracking.

This issue arises when the base metal surfaces are parallel and in contact before welding. The absence of opening, in combination with other factors, increases the risk of hot cracking during solidification and cooling.

Skewed Joint Considerations

In situations where fillet welds join plates or members at skewed angles, problems may arise if the implications of the skew geometry on the required weld size are overlooked during design or fabrication.

Proper beveling of the plate or member wall faying surface or increasing the weld size on the obtuse angle side is necessary to prevent a significant reduction in the effective throat and leg length of the fillet weld.

Best Practices for Root Opening Control

To mitigate the negative effects of an excessively large root opening, welding codes and proprietary practices typically define a maximum allowed gap.

In some cases, if the opening exceeds the specified limit, the welder may increase the fillet weld size within certain limits. However, in most applications, resizing of the fillet weld is not allowed, and the only corrective action is to reduce the opening before welding the joint.

Measuring and Monitoring Root Opening

Inspectors play a crucial role in monitoring and measuring the fillet weld opening before fit-up. However, once the fillet weld is deposited, measuring the opening becomes limited to the space adjacent to the weld. In joint geometries where the fillet welds cover the entire perimeter of a plate or member, direct measurement of the opening becomes impractical.

Future Research and Development

While current inspection methods offer limited assistance in detecting and measuring root openings and small root cracks, there is a need for innovative non-destructive examination (NDE) methods.

The development of an NDE method capable of providing in-situ gap measurements and identifying root cracks would greatly benefit the inspection process and ensure the integrity of fillet welds.