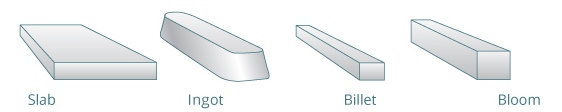

If you go to purchase semi-finished products from steel mill or supplier, you will notice four primary classifications of Semi-finished casting products:

- Ingots,

- Blooms,

- Billets, and

- Slabs.

Ingots, blooms, slabs, and billets are all different forms of raw material used in metalworking and manufacturing processes.

- An ingot is a material, usually metal, that is cast into a shape suitable for further processing. It is typically rectangular in shape.

- A bloom is a semi-finished, hot-rolled steel product with a square cross section, typically greater than 36 square inches. Blooms are used as raw material for the production of various steel products.

- A slab is a length of metal that is rectangular in cross-section. It is used as a starting material in the production of flat products such as plates, sheets, and strips.

- A billet is a length of metal that has a round or square cross-section, with an area less than 36 square inches. Billets are used as raw material for the production of bars, rods, and wire.

Difference between ingot, bloom, slab, and billet

Each type possesses distinct characteristics and applications & this is also one of most important query in ASNT NDT Level III Basic examination. Let’s see the differences between them and explore their significance in various manufacturing processes.

Ingot: Large and Versatile Casting Products

Ingots are substantial casting products, surpassing the size and shape of blooms, billets, and slabs.

While they typically exhibit rectangular or square cross-sections, the uniformity of their dimensions throughout their length is not a prerequisite. Ingots may vary in cross-sectional area. Their immense size makes them suitable for diverse industrial applications.

In the steelmaking process, ingots serve as the initial step among semi-finished casting products. However, ingots typically undergo a secondary procedure to shape them into a useful final product. This shaping process may involve cold or hot working, cutting, or milling, among other techniques.

Ingots are typically obtained through a batch-type process, where a specific amount of molten metal is poured into molds to solidify. Once solidified, the ingots are removed from the molds and undergo further shaping procedures to transform them into a desired form.

The secondary shaping procedures are necessary because ingots, in their initial form, are not directly suitable for most applications. By subjecting the ingots to processes like cold or hot working, cutting, or milling, manufacturers can refine their shape, size, and properties, resulting in a useful final product.

Bloom: The Rolling Material

Blooms, characterized by their rectangular or square cross-sections, boast a cross-sectional area greater than 36 square inches (230 cm2).

They serve as essential rolling materials in the manufacturing of rails, seamless pipes, and other products. Blooms play a vital role in shaping and forming various metal components.

Billet: The Product of Continuous Casting

Billets are another type of casting product, often produced using a continuous casting machine (CCM) in modern industry. They possess a square cross-section, with consistent dimensions throughout their length.

The cross-sectional area of a billet is always less than 36 square inches (230 cm2). Billets find extensive use in the manufacturing process of steel rebars, reinforcing structures with strength and durability.

Billets, an important type of semi-finished casting product, can be produced through two primary methods: direct continuous casting or extrusion, or indirectly through hot rolling an ingot or bloom. This versatility allows for the creation of billets in various shapes and sizes to meet specific manufacturing requirements.

Once the billets are created, they undergo further processing through profile rolling and drawing techniques. These processes refine the shape and dimensions of the billets, transforming them into more specialized forms. The end products derived from billets include bar stock and wire, which find widespread applications across industries.

By utilizing continuous casting, extrusion, or hot rolling, and subsequently processing billets through profile rolling and drawing, manufacturers can create a range of high-quality products tailored to their specific needs.

Slab: The Thinner Foundation

Slabs, characterized by their rectangular cross-sections, are thinner in thickness compared to blooms. They serve as the foundation for various downstream processes in metalworking. Slabs are a crucial starting point for the production of sheets, plates, and other flat metal products.

Slabs, a significant type of semi-finished casting product, can be created through direct continuous casting or indirectly by rolling an ingot on a slabbing mill. This allows for the production of slabs in different sizes and shapes to suit specific manufacturing requirements.

Once the slabs are formed, they undergo further processing through various techniques such as flat rolling, skelping, and pipe rolling. These processes refine the slabs, shaping them into more specialized forms and dimensions. The final products derived from slabs encompass a wide range of applications, including sheet metal, plates, strip metal, pipes, and tubes.

Utilizing continuous casting or rolling ingots on a slabbing mill, and subsequently processing slabs through flat rolling, skelping, and pipe rolling, manufacturers can produce a diverse array of high-quality products. Slabs serve as the foundation for the creation of sheet metal, plates, strip metal, pipes, and tubes, which find extensive use in numerous industries and applications.

Comparing Weight

When considering the weight of these semi-finished casting products, ingots hold the highest weight, followed by blooms, billets, and slabs. This weight hierarchy reflects the diverse applications and manufacturing requirements associated with each type.