Convex contour weld symbol

The convex weld symbol is quite enigmatic because it’s hard to think of a scenario where a convex shape would be needed for a butt/groove or fillet weld. Typically, all welds have a slightly convex shape to achieve the necessary throat thickness without using excessive weld metal.

Thus, this symbol could lead to confusion in a welding workshop as it might prompt a welder to use too much weld metal, resulting in potential issues and extra expenses, especially if no further instructions are given.

Convex contour weld symbol can be applied to:

- Fillet Weld,

- Groove Weld

- Plug Weld,

- Spot Weld,

- Seam Weld,

- Flare Weld,

- Edge Weld,

- Back/Backing Weld.

Convex contour weld symbol example

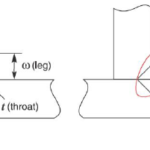

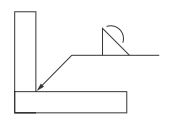

Convex contour weld symbol is a supplementary welding symbol and used along with main weld symbol. Below is an example of Convex contour weld symbol for a fillet welding. Here, Fillet weld symbol is supplemented with convex contour weld symbol.

What is a Convex Weld?

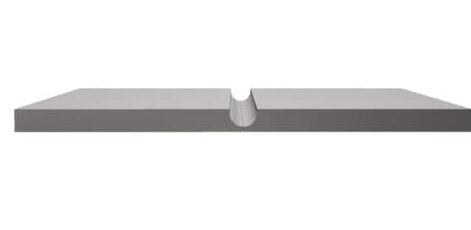

A convex weld refers to a type of weld joint where the welded surface has a slightly raised or curved profile, as opposed to a flat or concave profile. In other words, the surface of the weld has a slight bulge that extends beyond the surface of the base metal. This convex profile is typically produced by depositing weld metal in a manner that slightly protrudes beyond the base metal surface.

Convex welds are commonly used in situations where the weld needs to provide adequate strength and throat size while minimizing the amount of weld metal used. However, a weld with too much convexity can result in issues such as weld overlap, excessive convexity, and a weak weld.

Acceptance Criteria for Convex weld

AWS D1.1:Structural Welding Code sets limits for the convexity allowed for welds, which depends on the width of the weld face.

The maximum convexity allowed is 2mm for weld faces with a width of 8mm or less, 3mm for faces wider than 8mm but less than 25mm, and 5mm for faces wider than or equal to 25mm.

Excess weld metal refers to the metal that extends beyond the surface of a fillet or beyond a straight line connecting the toes of a butt/groove weld. Some people mistakenly refer to this excess metal as “reinforcement,” but this is incorrect because it rarely increases the static strength of a joint and can actually decrease the fatigue strength in many cases.

AWS Convex contour welding symbol

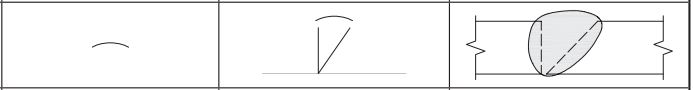

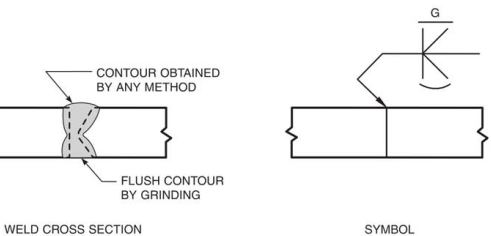

AWS Convex contour welding symbol is placed above the basic weld symbol and drawn as a outward curve as shown in below figure for arrow side weld. here, other side weld is Flat/ Flush contour.

ISO Convex contour welding symbol

ISO Convex contour welding symbol is similar to the AWS welding symbol system. It is must to specify the appropriate contour weld symbol along with the basic/ primary weld symbol for required weld profile in the fabrication drawing.