Bevel welding symbol is a Basic Weld Symbol used to provide information for bevel groove welds. The symbol highlight about the groove size, type and angle of bevels required for a welding joint.

In this article, we will learn about the different types of bevel welding symbols and provide you with some real-life examples to help you better understand their significance.

What is a Bevel Groove?

A bevel groove is a type of joint design used in welding that involves preparing only one side of the joining piece with a specific angle before the welding process. While the other side is kept without any weld preparation.

This angle is typically between the workpiece surface and a plane perpendicular to the surface, allowing for deeper penetration of the weld and a stronger joint.

The primary objective of a bevel groove is to create a larger surface area for the welding material. This is particularly beneficial for thicker materials, as a larger weld can be achieved, resulting in a joint with enhanced strength.

Types of Bevel Groove

There are two primary types of bevel grooves:

- Single Bevel Groove (Butt weld & T-Joint) and

- Double Bevel Groove (Butt weld & T-Joint).

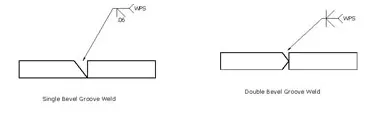

1. Single Bevel Groove

In a single bevel groove, only one of the workpieces is beveled. This creates an asymmetrical joint, with one side straight and the other angled.

The single bevel groove weld is particularly useful when the back side of the weld is not accessible. In such cases, the welder can achieve a full penetration weld from one side. It’s also commonly used in situations where the thickness of the material doesn’t require a double bevel for a full penetration weld.

2. Double Bevel Groove

A double bevel groove involves beveling both workpieces. This creates a symmetrical joint with an angle on both sides.

The double bevel groove is typically used for thicker materials where a single bevel won’t allow for a full penetration weld. This type of bevel provides a larger space for the welding material, ensuring a stronger joint.

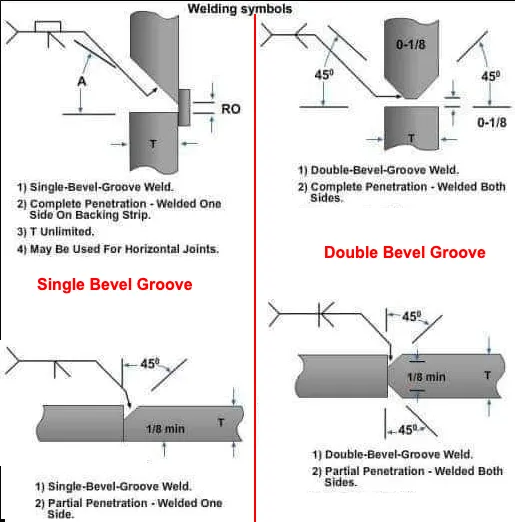

Below are examples for different types of Bevel Weld from Left to right:

- Single Bevel full penetration Groove Weld with Permanent Backing Weld symbol.

- Double Bevel full penetration Groove Weld.

- Single bevel Partial Penetration groove weld.

- Double Bevel Partial Penetration groove weld.

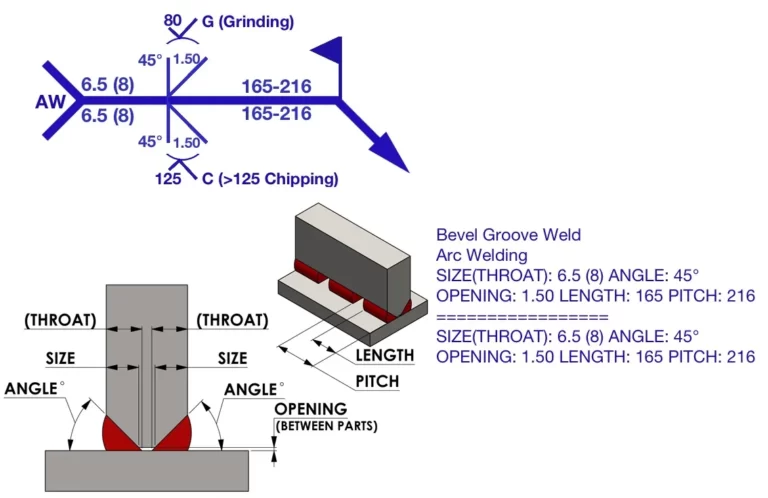

Welding Symbols for Bevel Grooves

Welding symbols provide a standardized way to communicate the specifications of a weld.

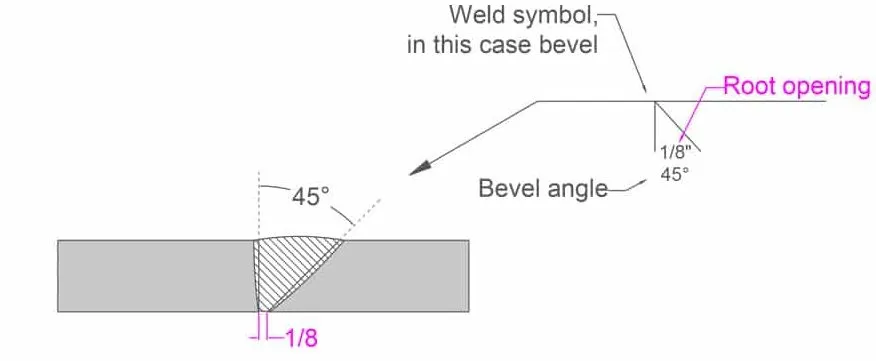

Welding Symbol for Single Bevel Groove

The welding symbol for a single bevel groove weld consists of a straight horizontal line (the reference line), a arrowline, and a bevel symbol.

The bevel symbol is a open triangle that appears either above or below the reference line. If the triangle appears above the reference line, the weld is to be made on the arrow side of the joint. If it appears below the reference line, the weld is to be made on the other side of the joint.

Welding Symbol for Double Bevel Groove

The welding symbol for a double bevel groove weld is similar to the single bevel groove weld symbol, but with two triangles (representing the bevels) instead of one.

These triangles can be placed back-to-back with vertices touching, indicating that both sides of the joint are to be prepared and welded. The placement of the triangles (above or below the reference line) still indicates which side of the joint the weld is to be made.

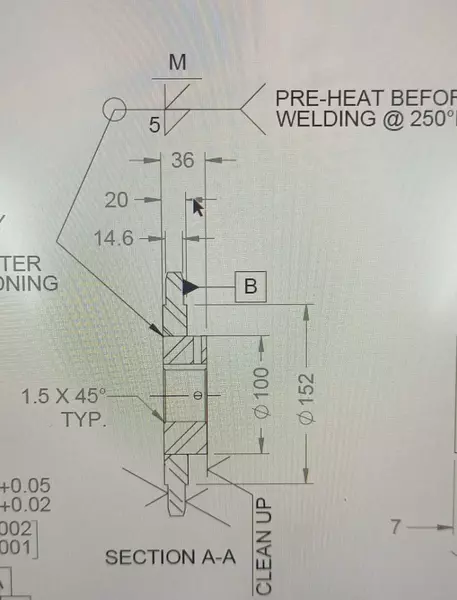

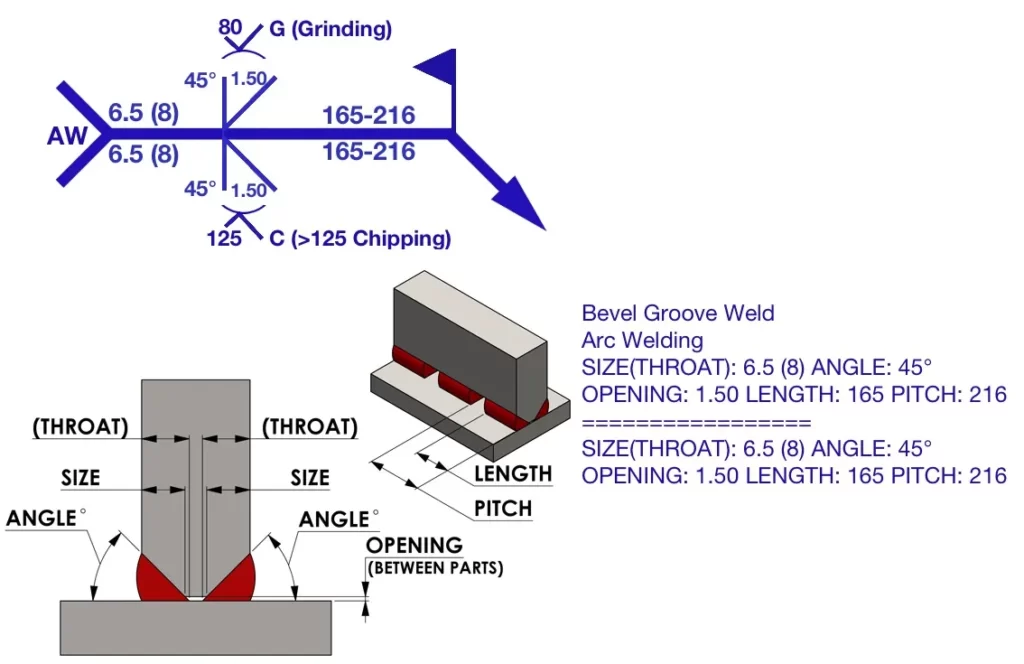

Example of Bevel Groove weld

Below is an actual example of bevel groove weld. Here, the current symbol cover:

- Bevel weld on arrow side with machining contour.

- Fillet weld as a sealing run with a leg length of 5 mm on other side.

- Apply welding preheat of 250 deg F.

- All welds are peripheral weld also called all around welding.