What is Weld Buildup?

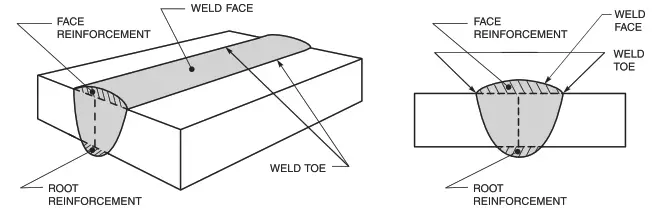

Weld buildup refers to the process of adding extra material to a welding joint to either increase its dimensions or enhance the strength of the joint.

This additional material can take the form of filler metal, cladding, or hard facing. Weld buildup can also be employed for repairing damaged welds or joints, restoring their structural integrity.

Importance of Weld Buildup

The significance of weld buildup lies in its ability to improve the strength and durability of a welding joint without starting from scratch.

By adding extra material strategically, welders can enhance the joint’s load-carrying capacity, resist wear and corrosion, and rectify defects or damages.

It allows for the modification and reinforcement of existing welds, making them better suited for their intended purpose.

When is Weld Buildup Utilized?

Weld buildup is commonly employed in the following scenarios:

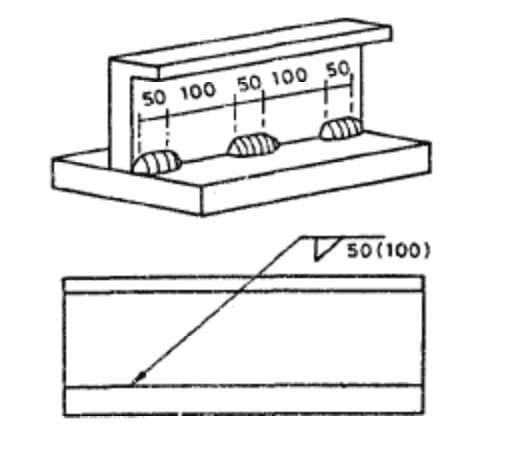

- Dimensional Enhancement: When the original dimensions of a weld are insufficient or do not meet the requirements of the application, weld buildup can be used to add material and achieve the desired size or shape.

- Strength Improvement: In situations where additional strength is needed, such as in high-stress applications, weld buildup can reinforce the joint by introducing more material at critical points.

- Repairing Damaged Welds or Joints: Weld buildup serves as an effective solution for repairing welds or joints that have experienced defects, cracks, or other forms of damage. By applying additional material, the integrity of the joint can be restored.

Buttering and Cladding in Welding

Buttering: Buttering involves depositing filler metal onto the surface of a weld joint to build up its dimensions or enhance its strength. This process is particularly useful when dealing with worn-out or undersized joints that require additional material for reinforcement.

Cladding: Cladding is a technique where a thin layer of material is applied to the surface of a weld joint. Its purpose is to improve the appearance of the joint or provide protection against corrosion, ensuring the underlying metal remains intact.

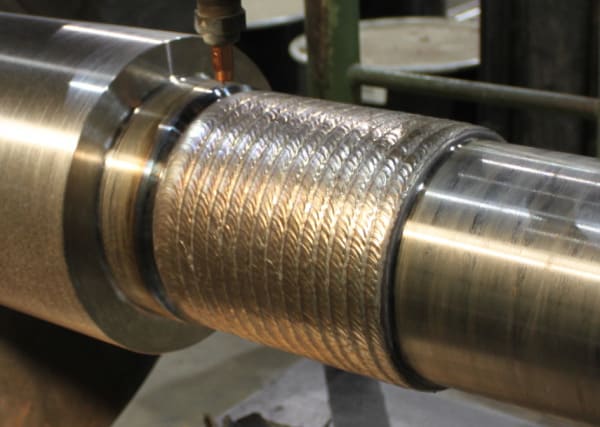

Weld Overlay: Weld overlay is a process similar to cladding, where a layer of material is applied to the surface of a base metal to provide protection against wear, corrosion, or other environmental factors. It is commonly used in industries such as oil and gas, where equipment and structures are exposed to harsh conditions.

Hardfacing: Hardfacing is a specific type of weld buildup technique that involves depositing a hard and wear-resistant material onto the surface of a component. This is done to increase its resistance to abrasion, erosion, and impact, extending its service life in high-wear environments.

Surfacing: Surfacing, also known as weld surfacing or weld deposition, is a general term that encompasses various processes of adding material to the surface of a base metal. It includes techniques such as cladding, hardfacing, and buttering, which are used to improve the properties and performance of the base metal.

Considerations for Material Selection

When performing weld buildup, the choice of materials is essential. Discuss factors to consider when selecting the filler metal or cladding material, such as compatibility with the base metal, desired properties (strength, corrosion resistance, etc.), and the specific operating conditions of the welded component.

Quality Control and Inspection

Highlight the importance of quality control and inspection during weld buildup processes. Discuss the use of non-destructive testing methods, such as visual inspection, radiographic testing, ultrasonic testing, or dye penetrant testing, to ensure the integrity and soundness of the weld buildup.