What is a Tack Weld Symbol?

A tack weld symbol is a graphical representation used in welding blueprints to indicate the location and size of tack welds. Tack welds are temporary welds that hold the workpieces in place before the final welding operation.

These welds are typically smaller and less structurally significant than the final welds. The tack weld symbol provides essential information to welders, ensuring accurate and efficient welding operations.

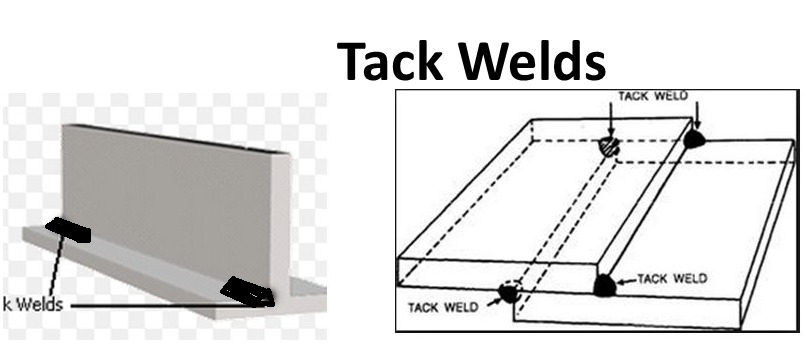

What is a tack weld?

A tack weld, also known as a tacking weld, is a temporary weld used to hold two or more pieces of metal together in proper alignment during the welding process. It is a quick and relatively small weld that provides temporary joint strength until the final welds are made.

Tack welding is commonly performed at the beginning stages of welding fabrication or assembly. It helps ensure that the components or parts being joined remain in the desired position and alignment before the full welding operation takes place.

By holding the pieces together, tack welds prevent movement or misalignment during the welding process, which could lead to welding defects or poor joint quality.

Tack welds are typically created using the same welding process and technique that will be used for the final welds. However, tack welds are deliberately made smaller and with less penetration compared to final welds. This is because tack welds are intended to be easily removable or fused into the final weld without compromising the integrity of the joint.

Once the tack welds are in place to secure the alignment, the welding process can proceed. After the completion of the final welds, the tack welds are often ground down or removed entirely to ensure a clean and finished appearance.

Tack welding is commonly used in various welding applications, including structural steel fabrication, pipe welding, sheet metal fabrication, and general metal fabrication. It helps increase the efficiency and accuracy of the welding process, ensuring proper alignment and minimizing distortion or movement of the workpieces during welding.

Understanding the Tack Weld Symbol

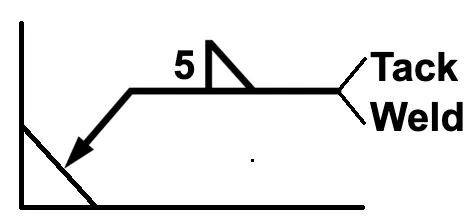

The tack weld symbol consists of a small triangle placed above the reference line along with mentioning TACK WELD in tail section, which represents the joint to be tack welded.

The symbol may also include additional information, such as the number of tack welds required or the distance between them.

Size and Orientation

The size of the tack weld symbol’s triangle indicates the size of the tack weld (e.g., 5 in above example mean leg length of 5 mm for this particular tack weld.

It is essential to understand that the size of the tack weld is not the same as the final weld. The size of the tack weld is typically smaller and depends on the specific welding requirements.

Number and Spacing

In some cases, the tack weld symbol may include a number next to the triangle, indicating the number of tack welds required. This information ensures that welders know how many tack welds to perform.

Additionally, the symbol may specify the spacing between the tack welds similar to intermittent fillet weld, ensuring uniformity and consistency in the welding process.

How to show tack weld on drawing?

To show a tack weld on a drawing, you can use a specific a “tack weld” in the tail section of the welding symbol as shown in the above example.

Importance of the Tack Weld Symbol

The tack weld symbol serves several crucial purposes in welding operations:

- Alignment: Tack welds are essential for aligning workpieces accurately before the final welding. The tack weld symbol provides clear instructions on where to place the tack welds, ensuring proper alignment and minimizing distortion during the final welding process.

- Efficiency: By indicating the size and location of tack welds, the symbol helps welders perform their tasks efficiently. It eliminates guesswork and ensures that the tack welds are appropriately sized and placed, saving time and effort.

- Safety: Tack welds play a vital role in holding workpieces together during the welding process. The tack weld symbol ensures that the tack welds are placed in the correct locations, preventing any potential hazards or accidents caused by misalignment or inadequate tack welds.

Conclusion

The tack weld symbol is a crucial element in welding operations, providing essential information to welders regarding the size, location, number, and spacing of tack welds.

By following the instructions provided by the symbol, welders can ensure accurate alignment, efficient welding, and enhanced safety.

Understanding and interpreting the tack weld symbol is essential for welders and engineers involved in the welding process, as it contributes to the overall quality and integrity of the final welds.