What is Square Groove Weld?

A square groove weld refers to a specific type of weld joint configuration where two metal pieces are joined together by creating a square-shaped groove at the joint.

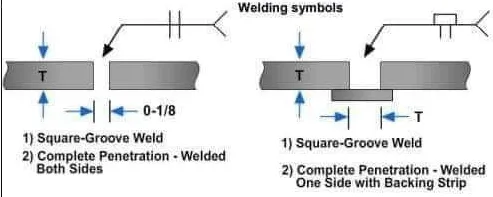

The groove is typically prepared by machining, grinding, or cutting the edges of the metal pieces to form a precise right-angle groove with square corners, i.e., without any bevel angle preparation on welding members to be joined as shown in the below figure.

Left to right:

- Square Groove Weld without Backing,

- Square Groove Weld with Backing.

Advantages of Square Groove Weld

The main Advantages of Square Groove Weld are:

- Provides a larger weld area for increased strength and load-bearing capacity.

- Offers improved penetration and fusion between the metal pieces.

- Enhances joint integrity and structural stability.

- Suitable for applications requiring high strength and resistance to heavy loads.

- Allows for efficient transfer of welding heat, resulting in a robust weld.

- Can be used in various welding processes, such as SMAW, GMAW, and FCAW.

- Provides a clean and visually appealing joint configuration.

- Offers versatility for welding different types of metals and thicknesses.

Square Groove Weld Symbol

The square groove weld symbol is a graphical representation used in welding blueprints or drawings to indicate the specific joint configuration and welding requirements for a square groove weld.