In this blog post, I will focus on one specific type of weld symbol: the V-groove weld symbol. We will explore its What is V-Groove Weld, features, applications, and how V-Groove Weld is represented in welding diagrams.

What is a V-Groove Weld?

According to the American Welding Society (AWS) A3.0 Standard Welding Terms and Definitions:

“a V-groove weld is a type of weld made in a groove on a workpiece surface, between workpiece edges, or between workpiece edges and surfaces.”

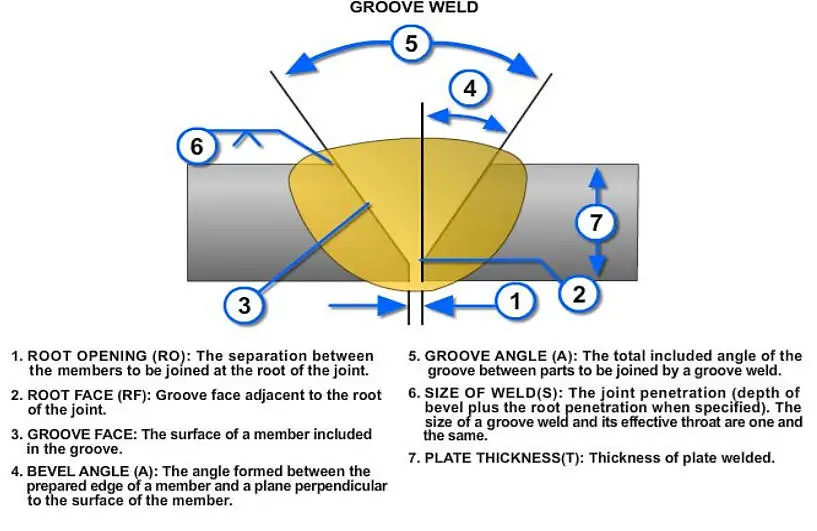

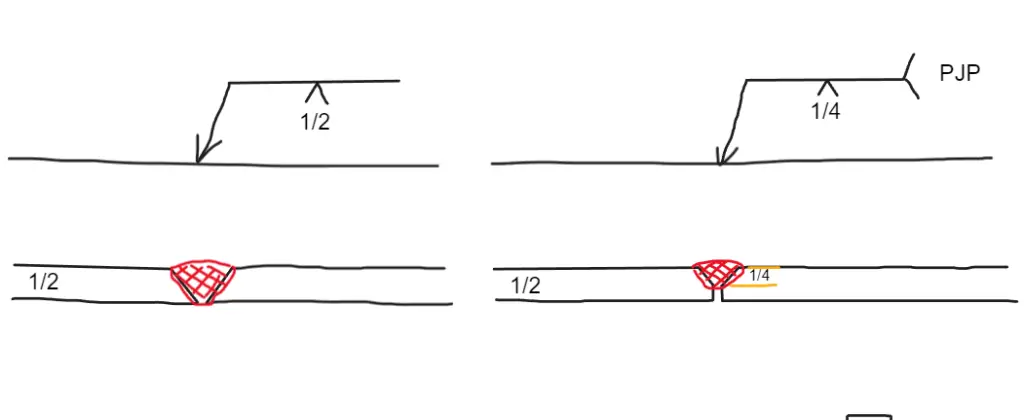

It is characterized by a channel or opening between two joint members that provides space to contain the weld metal. The V-groove weld requires the removal of metal from both faces of the workpieces, resulting in a V-shaped cross-section as shown in figure above.

V Groove Weld Types

V-groove welds are commonly categorized into several types based on the specific characteristics of the groove and the weld joint. The main types are:

- Single V-groove

- Double V-groove

Single V-groove

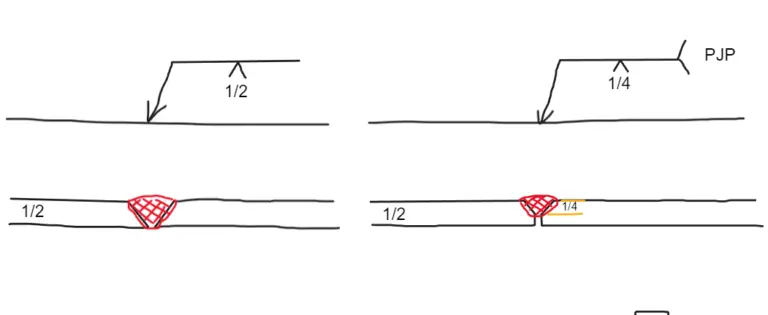

In a single V-groove weld, a V-shaped groove is prepared on one side of the joint, while the other side remains flat or square. This type of weld is often used when one side of the joint is inaccessible or when there are limitations in joint preparation.

Double V-groove

A double V-groove weld consists of V-shaped grooves on both sides of the joint, forming a V-joint on each workpiece. This type of weld allows for deep penetration and provides enhanced strength and load-bearing capacity.

Features of V-Groove Welds

- V-Groove welds are commonly used in applications where a strong and efficient joint is required.

- They are characterized by a V-shaped groove that is prepared on the edges of the base metal.

- V-Groove welds provide a larger surface area for the weld, resulting in increased strength and load-bearing capacity.

- These welds are often used in structural steel fabrication, piping systems, and heavy equipment manufacturing.

- V-Groove welds can be made using various welding processes such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or flux-cored arc welding (FCAW).

- They allow for deeper penetration and better fusion between the base metal and the filler material.

- V-Groove welds require precise preparation of the groove, including proper bevel angle and root face dimensions.

- They are commonly used for butt joints, where two pieces of metal are joined along their edges.

- V-Groove welds can be single-sided or double-sided, depending on the joint design and welding requirements.

- Proper weld size and reinforcement must be maintained to ensure the integrity and strength of the joint.

V Groove Welding Symbols

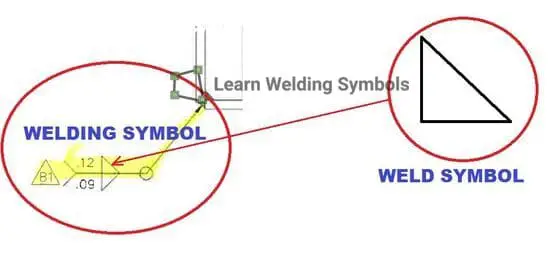

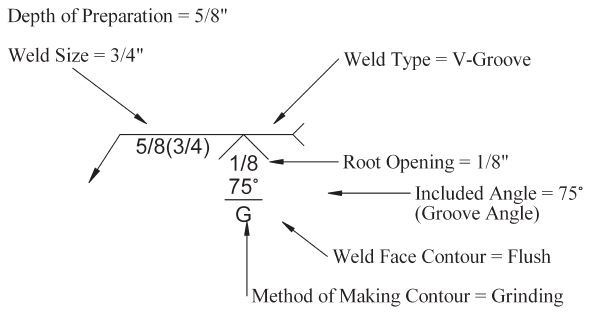

Similar to other weld symbols, the V-groove weld symbol consists of several elements. The reference line, always drawn horizontally, connects the arrow line and the tail. The arrow line points to the location of the weld.

Weld symbols drawn on the underside of the reference line, known as the arrow side, indicate the weld’s position on the components, while symbols located above the reference line are placed on the side opposite the arrow.

The tail, an optional element, contains important information about the weld. It typically includes the Weld Procedure Specification (WPS), which outlines the specific procedures and parameters followed by the welder. In some cases, additional notes and information regarding the weld may also be included in the tail.

Single V Groove Welding Symbol

A single V groove welding symbol typically consists of the following elements:

Single V-Groove weld symbol

- The reference line: A horizontal line that represents the base metal or the joint to be welded.

- The arrow: Indicates the location and direction of the weld. The arrow points towards the joint or the side where the weld is to be made.

- The groove symbol: A V-shaped symbol placed below the reference line, representing the V groove preparation on the edges of the base metal.

- The dimensions: Measurements and specifications related to the groove, such as the groove angle, root opening, and groove depth, may be indicated next to or below the groove symbol.

- Additional information: Any additional instructions or specifications, such as the welding process, filler material, or other requirements, may be included either above or below the reference line.

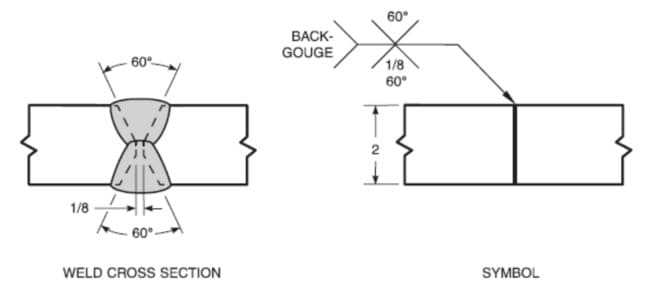

Double V Groove Welding Symbol

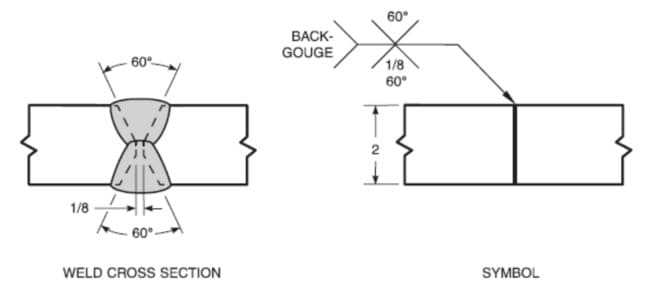

A double V-Groove welding symbol is similar to single V-Groove except that Two V-shaped symbols placed on the reference line, representing the double V groove preparation on the edges of the base metal.

The groove angle and root gap are shown inside the Groove weld symbol as shown in the below example.

In the below example,

- Two V placed on reference line refers to double V-Groove weld.

- 1/8 refers to root gap.

- 60 degree is the included angle of the groove.

- Tail specified Back gouging as an additional information applicable for this weld.

Applications of V-Groove Welds

V-groove welds find applications in a wide range of industries. They are commonly used in structural steel fabrication, automotive manufacturing, shipbuilding, and aerospace industries.

The V-groove configuration allows for increased weld strength and better load-bearing capabilities, making it suitable for joining thick materials or when high weld integrity is required.

Conclusion

Understanding welding symbols is crucial for effective communication and ensuring the quality and accuracy of welded joints. The V-groove weld symbol represents a specific type of weld that requires the removal of metal from both faces of the workpieces, forming a V-shaped groove.