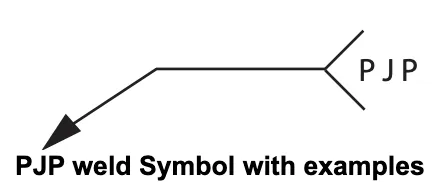

In welding, a partial penetration weld is represented by a specific symbol called the partial penetration weld symbol. This symbol is used on engineering drawings to indicate the type of weld joint and the desired level of penetration.

What is a Partial Penetration Weld?

A Partial penetration weld or also known as PJP Weld refers to a type of weld joint where the weld does not fully penetrate the thickness of the base metal. Instead, it only extends partially into the joint.

This type of weld is commonly used when the joint does not require full strength or when it is necessary to control the heat input to prevent distortion or other issues.

What is a Partial Penetration Weld Symbol?

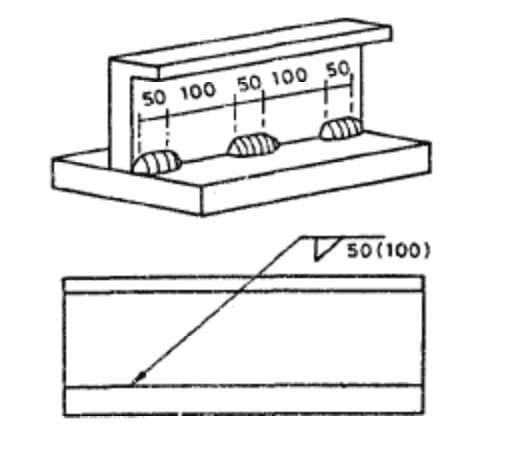

The partial penetration weld symbol is a graphical representation used to indicate the desired depth of penetration for a weld joint. It is typically used when a weld does not need to penetrate the full thickness of the base metal.

By using this symbol, engineers can precisely communicate the required weld depth to the welder, ensuring the weld joint meets the design specifications.

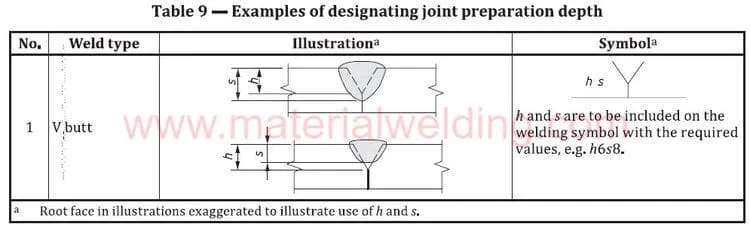

Components of the Partial Penetration Weld Symbol:

- Weld Symbol: E.g., V-Groove, J-Groove, U-Groove, Flare bevel, Bevel Groove, etc.

- Arrow: The arrow is attached to the reference line and points towards the side where the weld is to be made. It indicates the location of the weld joint.

- Tail

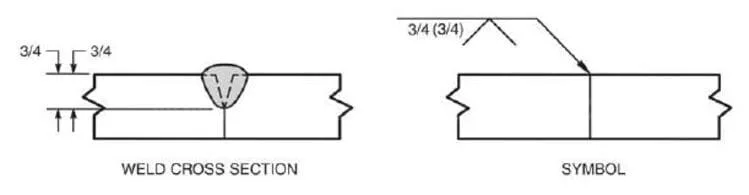

- Depth of Penetration: The depth of penetration is indicated by a number on the left side of weld symbol. This number represents the desired depth of the weld.

Interpreting the Partial Penetration Weld Symbol:

To interpret the partial penetration weld symbol correctly, one must understand the depth of penetration percentage. For example, if the number on left side of weld symbol is “3/4,” it means that the weld should penetrate 3/4 inch of the base metal thickness. The remaining depth will be left unfilled, resulting in a partial penetration weld joint.

Significance of the Partial Penetration Weld Symbol:

The partial penetration weld symbol offers several advantages in welding operations:

- Cost Efficiency: By specifying the desired depth of penetration, engineers can optimize the welding process, reducing material and labor costs. Partial penetration welds require less filler material and shorter welding times compared to full penetration welds.

- Structural Integrity: In certain applications, a partial penetration weld may be preferred to prevent distortion or stress concentration. By controlling the depth of penetration, engineers can ensure the structural integrity of the joint while minimizing potential weaknesses.

- Design Flexibility: The partial penetration weld symbol allows engineers to communicate specific welding requirements accurately. It provides flexibility in joint design, enabling the use of different welding techniques and reducing the risk of over-welding or under-welding.

Conclusion:

The partial penetration weld symbol is a valuable tool for engineers and fabricators involved in welding operations. By using this symbol, they can precisely communicate the desired depth of penetration, optimizing the welding process while ensuring structural integrity.

Understanding the components and interpretation of the partial penetration weld symbol is crucial for achieving high-quality weld joints and meeting design specifications.