Difference between Weld Symbol and Welding Symbol

A weld symbol and a welding symbol are related terms that are often confused, but they have different meanings in the context of welding.

What is Meant by a Weld Symbol?

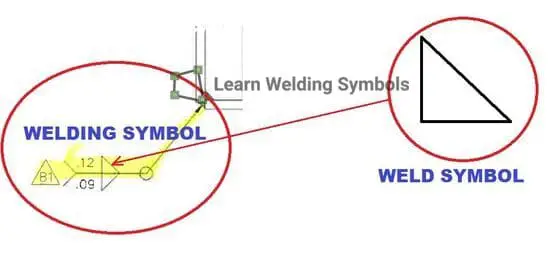

A weld symbol is a specific part of a welding symbol that indicates the type of weld to be performed. The weld symbol is a visual representation of the weld’s shape, dimensions, and other relevant information. Some common types of weld symbols include fillet, groove, plug, slot, and seam welds. The weld symbol is typically placed on a reference line within the welding symbol.

Below is an example of a Fillet weld made on both sides. Here, on left side, the complete details including arrow line, reference line and triangle shape means Welding Symbol. When we consider only, triangular shape, it is called Weld Symbol.

What is Meant by a Welding Symbol?

A welding symbol is a graphic representation that provides information about a weld joint’s requirements. It is a combination of different elements, including a reference line, arrow, weld symbols (mentioned above), and other supplementary symbols and dimensions. Welding symbols are used in technical drawings, blueprints, and engineering documents to communicate the necessary welding information between designers, engineers, and welders.

In summary, the weld symbol indicates the specific type of weld to be performed, while the welding symbol is a more comprehensive representation that includes the weld symbol along with other information necessary for the proper execution of the weld joint.

Examples of Weld Symbol

some common examples of welding symbols used in technical drawings:

- Fillet Weld Symbol: This symbol represents a fillet weld, which is a triangular-shaped weld between two pieces of metal. It is depicted as a small triangle placed on the intersection of the two lines being joined.

- Groove Weld Symbol: This symbol represents a groove weld, which is a weld created in a groove or channel between two pieces of metal. It is depicted as two parallel lines with arrows indicating the desired shape of the weld.

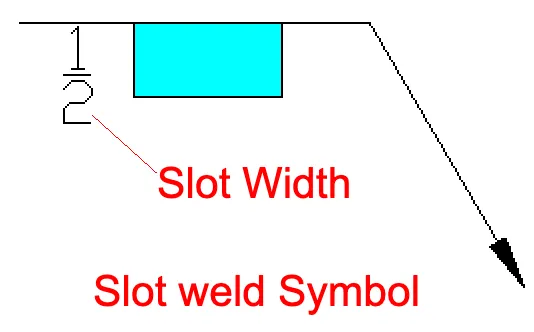

- Plug or Slot Weld Symbol: This symbol represents a plug or slot weld, which is a circular or rectangular weld made in a hole or slot in one piece of metal to join it to another. It is depicted as a circle or rectangle with an arrow pointing to the location of the weld.

- Spot Weld Symbol: This symbol represents a spot weld, which is a weld made by applying pressure and heat to two or more metal surfaces. It is depicted as a small dot placed on the intersection of the two lines being joined.

- Seam Weld Symbol: This symbol represents a seam weld, which is a continuous weld made along the length of two or more pieces of metal. It is depicted as a straight line with short dashes placed above or below the reference line.

- Surfacing Weld Symbol: This symbol represents a surfacing weld, which is a weld used to build up or reinforce a surface. It is depicted as a series of short, connected dashes placed above or below the reference line.

- Back or Backing Weld Symbol: This symbol represents a back or backing weld, which is a weld made on the opposite side of the main weld to provide additional support or reinforcement. It is depicted as a straight line with a hump or series of arcs placed on the opposite side of the reference line.

These are just a few examples of welding symbols commonly used in technical drawings. There are many other symbols and variations depending on specific requirements and standards.