What is a Corner Weld?

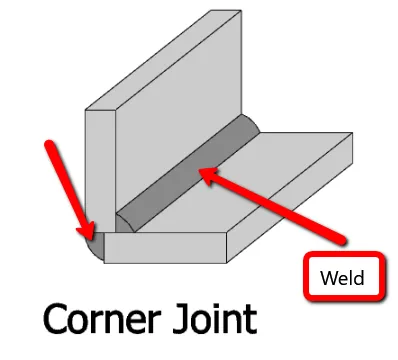

A corner weld refers to a type of weld joint that is formed at the intersection or corner of two metal pieces. It is commonly used in various welding applications, such as construction, fabrication, and manufacturing.

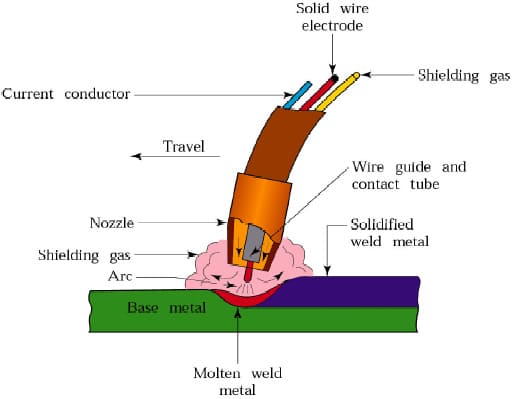

The corner weld is typically created by fusing the two metal pieces together along the joint using various welding techniques, such as arc welding, MIG (Metal Inert Gas) welding, or TIG (Tungsten Inert Gas) welding. The welding process involves melting the base metals and adding a filler material, if necessary, to create a strong and durable bond.

The weld size of corner weld can be defined using Corner weld symbol.

Corner welds are often used to join metal components at right angles, forming 90-degree corners. They provide structural integrity and stability to the welded assembly, making it suitable for load-bearing applications.

Additionally, corner welds can be found in various industries, including automotive, aerospace, construction, and general metal fabrication.

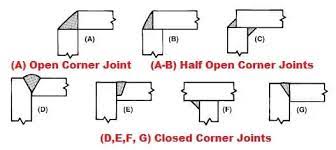

Proper preparation and execution are crucial for creating high-quality corner welds. Factors such as joint design, material type, welding technique, and welding parameters play significant roles in achieving a successful and reliable weld.

Welders must follow industry standards such as AWS D1.1, safety practices, and applicable welding codes to ensure the integrity of the corner weld and the overall strength of the welded structure.