Fillet welds play a crucial role in creating strong and durable connections between metals. These seemingly unassuming welds are found in various industries, from construction to manufacturing, and understanding their symbols and sizes is essential for achieving structural integrity.

❓❓❓❓But what exactly is a fillet weld? ❓❓❓❓❓

Simply put, it’s a type of joint where two metal pieces are joined together at an angle forming an L-shape. While its appearance may seem straightforward, the importance of accurate sizing cannot be overstated.

Fillet Weld Size

✨When it comes to fillet welds, size matters✨ – not just for aesthetics but also for ensuring the strength and reliability of the welded structures.

A correctly sized fillet weld not only provides ample reinforcement but also helps distribute stresses evenly across the joint surface. This ultimately enhances the overall stability and durability of welded assemblies.

Fillet weld size is measured either by:

- ✨ Leg Length (Z) ✨ or

- ✨ Throat Size (a) ✨

However, determining the right size for a fillet weld can be quite challenging. It requires careful consideration of factors such as material thicknesses, design requirements, load-bearing capacity, and welding techniques employed – all culminating in selecting an appropriate symbol that accurately represents the intended dimensions on engineering drawings or blueprints.

Understanding Fillet Weld Symbols

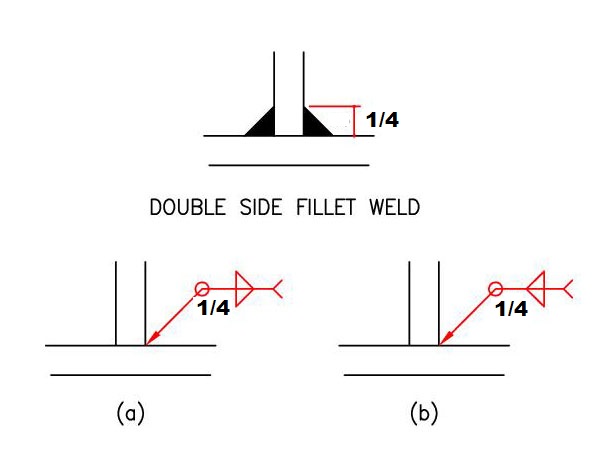

Fillet weld symbols are a standard way of representing welds on engineering drawings. These symbols provide important information about the size, length, and location of fillet welds required for a particular joint or connection. One commonly used fillet weld symbol is the 1/4 fillet weld symbol.

The 1/4 fillet weld symbol represents a fillet weld with a leg length equal to one-quarter inch (or any other specified unit of measurement).

It consists of:

- An arrow line,

- A reference line,

- A fillet weld symbol placed on the reference line,

- Weld size as 1/4 placed on the left side of the weld symbol.

On top of this line, there is typically a number written that specifies the desired leg length for the fillet weld. In this case, it would be 1/4 to represent a quarter-inch leg length.

Interpreting fillet weld symbols can be done using industry-standard conventions. For instance, if there is no number written above or below the symbol’s reference line after specifying its use in another part drawing related to welding but without specific dimensions given then assume all sides have identical sizes as shown elsewhere like under design code or specifications.

Defining Fillet Weld Size

Fillet weld size refers to the length and width of the triangular-shaped fillet weld that is used to join two pieces of metal. It is an essential aspect of welding as it determines the strength and integrity of the joint. The size of a fillet weld is specified on engineering drawings using various measurements, primarily in terms of leg length.

The leg length refers to the distance from the root (the junction between the base metal and weld) to where each side of the triangular fillet meets with the base material. It can be denoted by a symbol on welding blueprints, often represented by capital letters such as ‘Z’ or other variations depending on industry standards.

Selecting an appropriate fillet weld size requires careful consideration of factors like load-bearing requirements, material thickness, and desired aesthetics. Design specifications outline these criteria for different applications.

In practical terms, selecting a fillet weld size involves choosing from a range provided based on engineering recommendations or codes. These sizes typically vary in increments ranging from 1/16th inch up to multiple inches depending upon project requirements. The chosen fillet weld size should ensure sufficient strength for structural integrity while avoiding excessive materials usage and associated costs.