Strip cladding is a very useful welding technique used in various industries to protect and enhance the durability of surfaces by preventing corrosion, erosion, and other environmental damages. Whether it’s extending the lifespan of industrial equipment or adding an extra layer of protection to critical components, strip cladding offers a multitude of benefits.

But what exactly is strip cladding, and how does it work?

What is Strip Cladding?

In its simplest form, strip cladding can be defined as a process where a protective layer or additional material is bonded onto a base material using heat and pressure.

This method involves applying strips made from specialized materials over the surface that needs coating or building up. These strips are typically composed of alloys, ceramics, or metal powders in various forms such as ribbons, rods, foils, or wires.

The fundamental principle behind strip cladding lies in its ability to create cohesive bonds between the added material and the underlying substrate through controlled fusion.

“Strip cladding, also known as strip welding or strip overlay, is a welding process used to apply a layer of material onto the surface of a base metal. It is commonly used in industries such as oil and gas, power generation, and aerospace to enhance the properties and performance of components.”

In strip cladding, a thin strip of cladding material, often in the form of a metal wire or ribbon, is fed into a welding torch or equipment. The strip is melted by a heat source, typically an arc generated by a welding power source, and deposited onto the base metal surface.

The cladding material is chosen based on its specific properties, such as corrosion resistance, wear resistance, or high-temperature resistance. By applying the cladding layer, the base metal can gain improved resistance to environmental factors, increased strength, or enhanced surface properties.

Strip Cladding Process Types

Strip Cladding Process has two main Types:

- SAW Strip Cladding

- ESW Strip Cladding.

SAW Strip Cladding

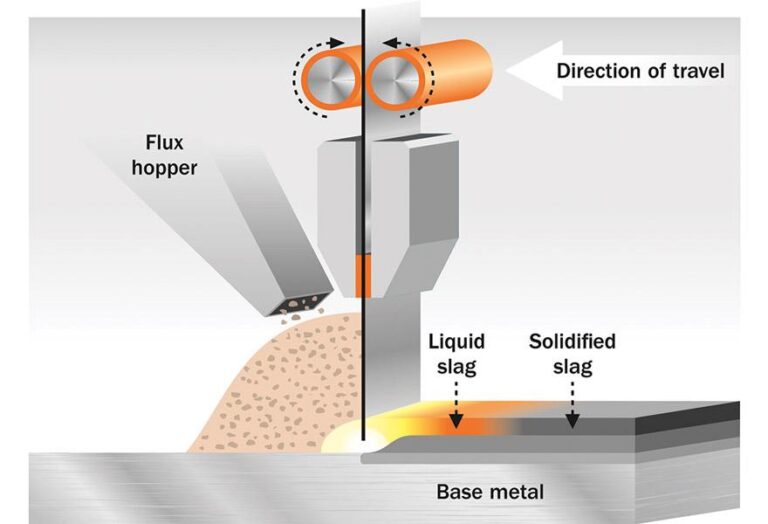

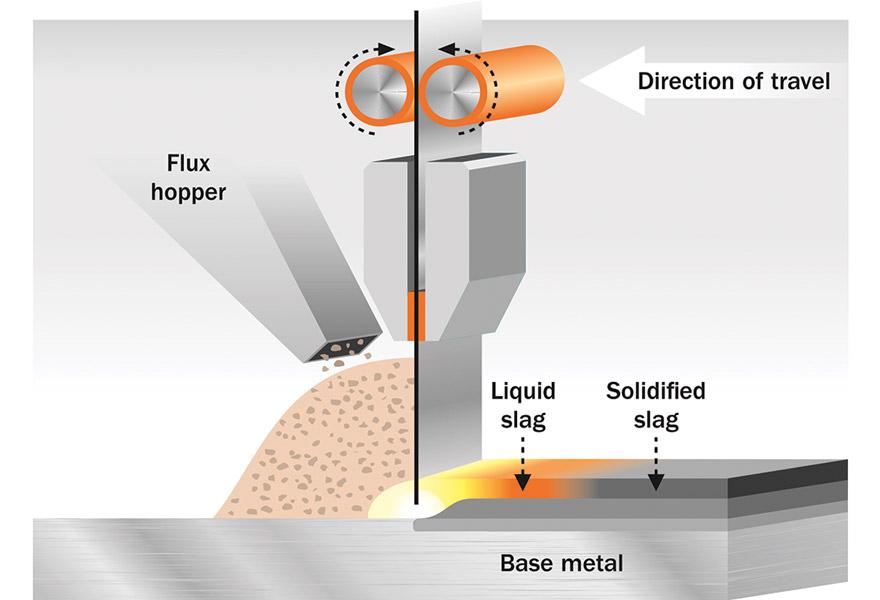

The widely recognized SAW (Submerged Arc Welding) method has been extensively employed with strip electrodes since the mid-1960s. This technique utilizes strip electrodes measuring typically 60 x 0.5 mm or 90 x 0.5 mm as the positive electrode.

An electric arc is created between the strip and the workpiece, while a flux is used to generate a molten slag. The molten slag acts as a protective barrier for the weld pool, preventing atmospheric contamination and ensuring a smooth weld bead surface.

ESW Strip Cladding

ESW (Electroslag strip cladding) is a development derived from submerged arc strip cladding and has rapidly established itself as a dependable process for achieving high deposition rates.

Unlike SAW strip cladding, ESW strip cladding is associated with resistance welding methods. It involves the heating of a molten electrically conductive slag through ohmic resistance.

Unlike SAW, ESW strip cladding does not involve an arc between the strip electrode and the parent material. Instead, the heat generated by the molten slag melts the surface of the base material, and the edge of the strip electrode is submerged in the slag and flux.

Comparison of ESW with Strip Cladding Process

Penetration

ESW achieves lower penetration compared to SAW strip cladding, as the molten slag pool is responsible for melting both the strip and some of the parent material.

Welding Currents and Equipment:

ESW employs higher welding currents, necessitating more robust welding heads. The contact jaws also require water-cooling due to the elevated temperature (around 2300°C) of the slag pool.

Features of ESW

- Increased deposition rate of 60% to 80%

- Reduced dilution (10%–15%) from the base material due to shallower penetration

- Lower arc voltage (24–26 V)

- Higher amperage and current density

- Increased welding speed (50%–200%)

- Comparable heat input

- Lower flux consumption (approximately 0.5 kg/kg strip)

- Slower solidification rate, aiding degassing and enhancing resistance to porosity, hot cracking, and corrosion

Applications of Strip Cladding

Applications of Strip Cladding:

- Corrosion Protection: Strip cladding is commonly used to provide corrosion protection to various components and structures. By applying a corrosion-resistant alloy strip onto the surface of a base metal, strip cladding forms a protective barrier against corrosive environments. This is particularly beneficial in industries such as oil and gas, chemical processing, and marine applications.

- Wear Resistance: Strip cladding is used to enhance the wear resistance of surfaces that are subjected to abrasive or erosive conditions. By cladding a wear-resistant alloy onto the base material, the surface can withstand friction, impact, and abrasive forces. This is valuable in industries such as mining, construction, and manufacturing of cutting tools.

- Heat Resistance: Strip cladding is employed to provide heat resistance to components that operate in high-temperature environments. By applying a heat-resistant alloy strip, the cladding protects the base material from thermal degradation, oxidation, and high-temperature corrosion. This is crucial in industries such as power generation, aerospace, and furnace manufacturing.

- Dimensional Restoration: Strip cladding is utilized for restoring the dimensions and functionality of worn or damaged components. By applying the appropriate alloy strip, the cladding process rebuilds the worn surfaces, restoring their original shape and dimensions. This is commonly seen in industries such as automotive, machinery, and tooling.

- Metallurgical Bonding: Strip cladding facilitates the metallurgical bonding of dissimilar metals or alloys. By cladding a compatible strip onto the base material, a strong metallurgical bond is formed, allowing for the joining of different materials with distinct properties. This is utilized in industries such as automotive, aerospace, and fabrication of composite materials.

- Surface Modification: Strip cladding is employed for surface modification purposes, including improving surface roughness, texture, or appearance. By cladding a decorative or functional strip onto the base material, the surface properties can be altered to meet specific requirements. This is utilized in industries such as architecture, interior design, and consumer goods manufacturing.

Fluxes for ESW

The ESW process necessitates a slag pool with specific ohmic resistance characteristics. When compared to SAW cladding, the electrical conductance must be higher in order to prevent arc flash, which can disrupt the process.

The conductivity, solidification range, and viscosity of the molten slag are influenced by the composition of the welding flux.

To achieve higher cladding speeds while using high welding currents, it becomes crucial to employ fluxes with elevated electrical conductivity and reduced viscosity. These properties enable efficient and smooth operation of the ESW process while maintaining the desired cladding speed.

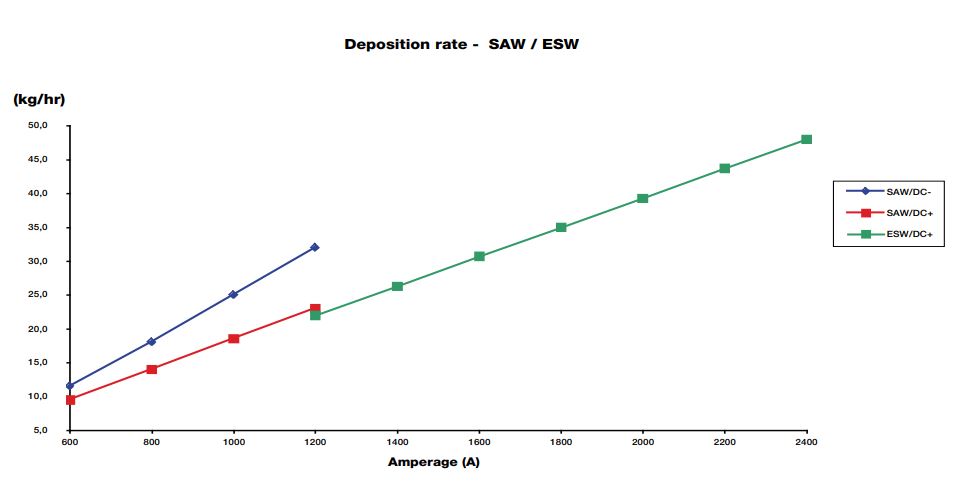

Deposition rate of Electroslag Strip Cladding

he deposition rate of electroslag strip cladding (ESW) can vary depending on various factors such as the specific welding parameters, strip size, welding current, and the type of material being deposited. However, ESW strip cladding generally offers significantly higher deposition rates compared to other strip cladding processes.

Typically, the deposition rate in ESW strip cladding can range from 60% to 80% higher than traditional strip cladding methods. This means that ESW strip cladding can achieve a much faster rate of material deposition, allowing for increased productivity and reduced production time.

The higher deposition rate in ESW strip cladding is mainly attributed to the use of higher welding currents and the unique characteristics of the electroslag process. The molten electrically conductive slag in ESW generates a significant amount of heat, resulting in a faster melting and deposition of the strip electrode material onto the workpiece.

When and how do you use strip cladding?

Strip cladding is a versatile welding process used in various industries for a range of applications. Here are some scenarios and methods where strip cladding is commonly employed:

- Corrosion Protection:

- Apply a corrosion-resistant alloy strip onto the surface of a base metal to protect it from corrosive environments.

- Commonly used in industries such as oil and gas, chemical processing, and marine applications.

- Wear Resistance:

- Clad a wear-resistant alloy strip onto surfaces subjected to abrasive or erosive conditions.

- Provides enhanced durability and longevity in industries like mining, construction, and manufacturing of cutting tools.

- Heat Resistance:

- Apply a heat-resistant alloy strip to components operating in high-temperature environments.

- Protects against thermal degradation, oxidation, and high-temperature corrosion.

- Crucial in industries such as power generation, aerospace, and furnace manufacturing.

- Dimensional Restoration:

- Use strip cladding to restore dimensions and functionality of worn or damaged components.

- Rebuild worn surfaces by applying an appropriate alloy strip.

- Commonly seen in industries like automotive, machinery, and tooling.

- Metallurgical Bonding:

- Facilitate the bonding of dissimilar metals or alloys by cladding a compatible strip onto the base material.

- Allows for the joining of different materials with distinct properties.

- Utilized in industries such as automotive, aerospace, and fabrication of composite materials.

- Surface Modification:

- Employ strip cladding for surface modification purposes, including improving roughness, texture, or appearance.

- Clad a decorative or functional strip onto the base material to alter surface properties.

- Utilized in industries such as architecture, interior design, and consumer goods manufacturing.