What is Self Shielded Flux Cored Arc Welding (FCAW-S)?

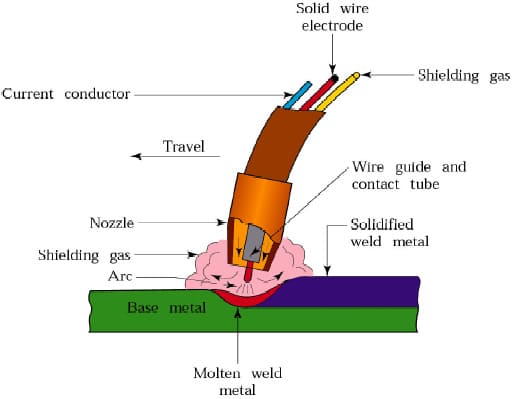

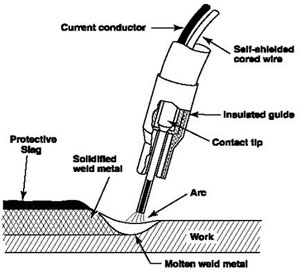

Self Shielded Flux Cored Arc Welding (FCAW-S) is a variation of the flux cored arc welding process where the shielding gas is obtained exclusively from the flux within the electrode.

“S- means Self- Shielded Welding Wire.”

FCAW-S, also known as self-shielded flux-cored wires, is often likened to an “inside-out” stick electrode. Unlike other welding processes that rely on external shielding gases,

FCAW-S wires utilize their slag system and the gases generated from chemical reactions in the arc to protect the molten metal from atmospheric contamination.

This type of welding is commonly used in applications where it is not feasible or practical to use an external gas source, such as in field or construction work.

Self Shielded Flux Cored Arc Welding (FCAW-S) Basics

GMAW (MIG) and gas-shielded flux-cored (FCAW-G) wires achieve the best welding results when using direct current electrode positive (DCEP) polarity. However, the recommended or most stable polarity for FCAW-S depends on the specific core elements (arc stabilizers) present in the wire being used.

While the majority of FCAW-S wires perform optimally with direct current electrode-negative (DCEN) polarity, there are a few that exhibit greater stability when used with DCEP.

In GMAW, a smooth V-groove in the wire feeder’s drive rolls is utilized to grip the solid wire and feed it through the welding gun. Unfortunately, this tight squeeze of the smooth V-groove can cause deformation in cored wires.

To achieve the same pushing force without excessive squeezing, FCAW-S wires require knurled V-groove drive rolls that grip the wire sheath, providing the necessary pushing force without causing deformation.

FCAW-S Welding Wires

Technological advancements have improved self-shielded FCAW wires, enhancing their mechanical properties and welding performance. These wires offer better control over the weld pool and arc, increasing productivity through continuous welding.

Contractors commonly use two types of self-shielded flux-cored wires, namely T-11 and T-8, for construction welding. Classified as:

- AWS E71T-11 and

- AWS E71T-8,

respectively, these wires are versatile options suitable for general-purpose welding in all positions.

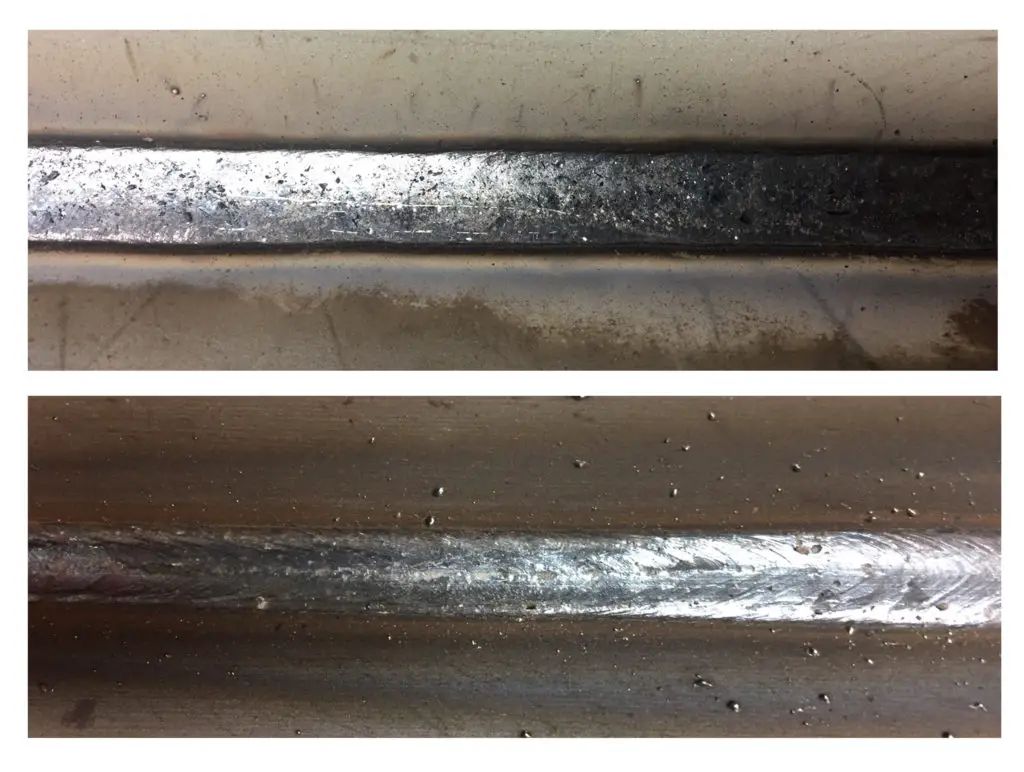

Choosing the right equipment is crucial when using T-11 or T-8 wires. It is recommended to use a constant voltage (CV) power source instead of a constant current (CC) power source. CC power sources can cause fluctuations that result in inconsistent quality and weld defects like porosity.

Conversely, a CV power source provides a stable voltage, ensuring a smooth arc performance and compensating for power variations on jobsites with multiple loads.

Both T-8 and T-11 wires should be operated with direct current electrode negative (DCEN) or straight polarity, which differs from most wire filler metals. Using the incorrect polarity can lead to poor welding performance and increased spatter levels.

Advantages of Self Shielded Flux Cored Arc Welding

One of the notable advantages of FCAW-S is its suitability for outdoor welding tasks.

Since it doesn’t require an external shielding gas, the risk of gas dispersion due to wind is eliminated, minimizing the occurrence of porosity commonly associated with gas-shielded processes.

- Versatility: FCAW-S is a highly versatile welding process that can be used on a variety of materials, including steel, stainless steel, and aluminum.

- All-Position Welding: FCAW-S is capable of welding in all positions, making it ideal for projects that require welding in difficult or hard-to-reach areas.

- No External Gas Source Required: Unlike other welding processes, FCAW-S does not rely on an external gas source for shielding. The shielding gas is generated from the flux within the electrode, making it convenient for field or construction work where access to an external gas supply may be limited.

Considerations for Self Shielded Flux Cored Arc Welding

- Electrode Selection: It is crucial to use an electrode specifically designed for self shielded flux cored arc welding to ensure optimal performance and quality welds.

- Welding Parameters: Correct welding parameters must be employed to achieve high-quality welds. This includes setting the appropriate voltage, current, and wire feed speed based on the specific application and material being welded.

Importance of flux in FCAW-S

The flux core within the FCAW-S wire serves multiple purposes, including:

- Deoxidizing and denitrifying the molten metal, ensuring its purity.

- Creating a protective slag that not only shields the weld but also shapes the bead and can even support out-of-position welding.

- Introducing alloying elements into the weld metal, enabling the attainment of desired mechanical properties.

- Influencing welding characteristics, such as deep penetration capabilities and high deposition rates.

Consider FCAW-S as an extension of stick welding, offering enhanced productivity through semi-automatic processes while being applicable to a wide range of applications similar to stick electrodes.