Root pass in Welding lays the foundation for creating a strong and quality weld joints.

What is the Root Pass in Welding?

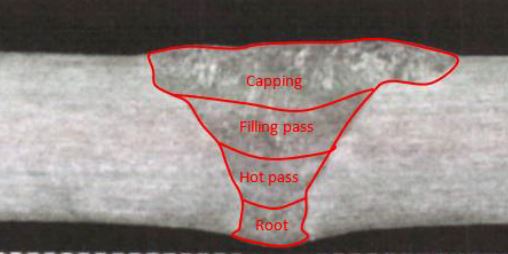

The root pass marks the initial weld bead deposited in a multi-pass welding joint. Sometimes referred to as the starting or initial pass, it serves as the bedrock for building up the desired thickness of the final weld bead.

“Simply put, it is the first layer of material added during the welding process, playing a critical role in ensuring the stability and strength of the overall weld joint.“

Root Pass in Groove (Butt Joint Welding)

The root pass in welding refers to the initial pass made in a multi-run weld, regardless of whether it is a butt weld from one side or both sides.

Its name originates from its primary objective of ensuring complete fusion, specifically full penetration at the root of the weld.

This concept applies to butt welds executed from a single side, as well as to those welded from both sides.

In the latter case, the root pass is the first weld performed from each side, emphasizing the importance of achieving fusion at the root.

Importance of a Properly Executed Root Pass

The root pass is vital for achieving a sound foundation for subsequent weld passes. To ensure high weld integrity, it is crucial to execute the root pass with precision, employing the correct technique and welding parameters.

A well-executed root pass establishes a solid bond between the base metal and the filler metal, forming a strong and reliable weld joint.

Common Challenges and Solutions

While performing the root pass, welders may encounter certain challenges that can affect the quality of the weld.

Incomplete penetration, lack of fusion, porosity, and slag inclusion are some common problems that can arise. Incomplete penetration occurs when the weld bead does not fully penetrate the metal thickness.

This can be remedied by adjusting the welding current or slowing down the welding speed.

- Lack of fusion is addressed by ensuring proper technique, welding parameters, and clean base metal surface.

- Porosity, which manifests as tiny voids in the weld bead, can be minimized by avoiding contaminants and maintaining suitable shielding gas.

- Slag inclusion can be prevented by properly managing previous slag and using uphill welding direction.

Tips for Successful Root Pass Welding

To achieve optimal results during the root pass, here are some valuable tips to consider:

- Technique and Parameters: Pay close attention to the welding technique, maintaining a steady hand and applying appropriate heat and pressure for effective fusion.

- Welding Speed: Find the right balance in welding speed to prevent incomplete penetration or overheating. Adjust the speed based on the material thickness and welding current.

- Base Metal Preparation: Ensure the base metal is clean and free from contaminants. This promotes better adhesion and reduces the risk of defects.

- Electrode Selection: Choose the appropriate welding electrode based on the specific requirements of the application. General-purpose electrodes may suffice in most cases, but specialty electrodes might be necessary for certain materials and thicknesses.