What is a Weld Face in Welding?

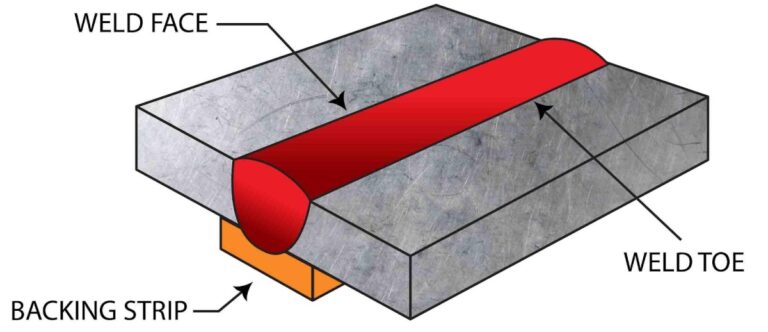

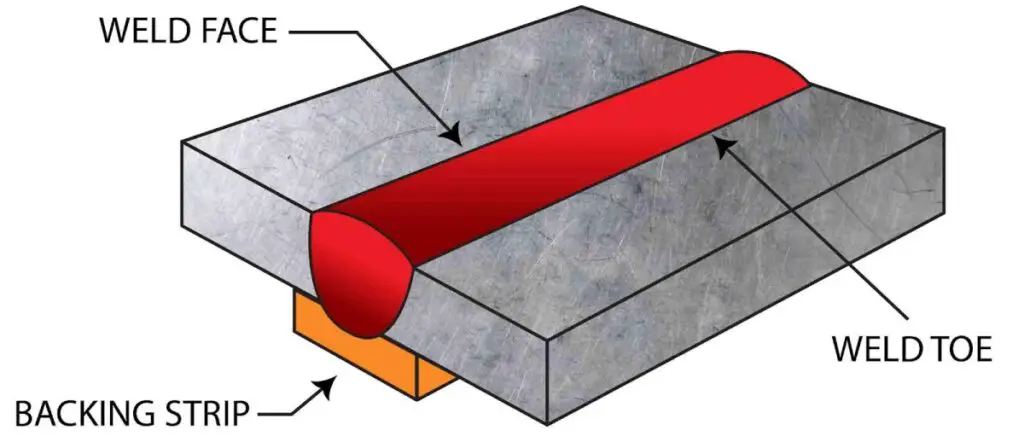

In welding, a weld face refers to the visible surface of a weld on the side from which the welding was performed. It is the smooth and rounded surface that is formed as a result of the welding process.

The Purpose of the Weld Face

The primary purpose of the weld face is to create a smooth and strong joint between two metal pieces. It ensures that the welded connection is secure and capable of withstanding the intended loads and stresses.

Types of Weld Faces

There are various types of weld faces, each with its own advantages and disadvantages:

- V-Groove Weld Face: This type of weld face is achieved by using a V-shaped groove in the metal. It offers a strong and clean joint, but achieving consistent V-groove weld faces can be challenging.

- U-Groove Weld Face: The U-groove weld face is created by using a U-shaped groove in the metal. It provides a strong and clean joint but, similar to V-groove weld faces, can be difficult to achieve consistently.

- J-Groove Weld Face: A J-groove weld face is formed by using a J-shaped groove in the metal. It offers a strong and clean joint, but like the previous types, maintaining consistency can be challenging.

- Butt Weld Face: The butt weld face is created by welding two metal pieces together without using any groove. It results in a very strong joint, but achieving a clean and consistent butt weld face can be difficult.

- Flare Bevel Weld Face: The flare bevel weld face is obtained by welding two metal pieces together and then grinding the surface to create a flared bevel. It provides a strong and clean joint, but consistency can be challenging to achieve.

Understanding Weld Root Face

The weld root face refers to the surface of the metal at the bottom of the groove where the welding process begins. Its purpose is to provide a strong and clean starting point for the weld.

The Five Parts of a Weld

A weld consists of five main parts:

- Root: The root is the area where the weld begins, typically at the bottom of the groove.

- Face: The face is the visible surface of the weld.

- Cap: The cap is the uppermost portion of the weld, often used to provide additional reinforcement or aesthetic appearance.

- Bevel: The bevel is a sloped or angled edge that is typically prepared on the metal pieces to facilitate welding.

- Reinforcement: Reinforcement refers to any additional metal added to reinforce the weld, particularly in cases where the metal pieces being joined have different thicknesses.

Weld Face Reinforcement

Weld face reinforcement involves reinforcing the weld face with extra metal. This technique is commonly used when joining metal pieces of varying thicknesses to ensure a stronger and more reliable joint.