What is a Stringer Bead in Welding?

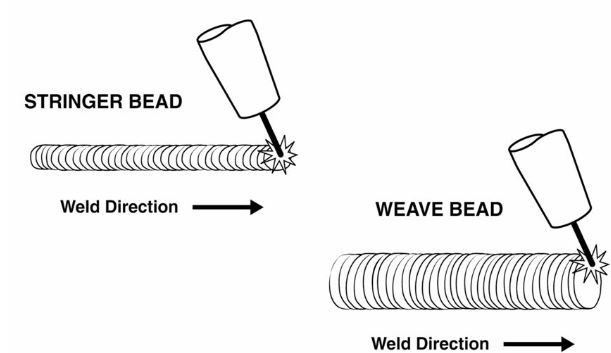

In welding, a stringer bead refers to a specific welding technique used to deposit a weld bead in a straight line along the joint.

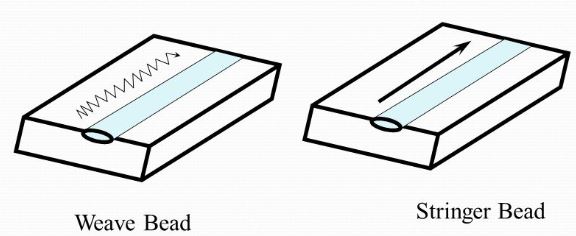

It involves moving the welding electrode or the welding torch consistently without any side-to-side motion. The resulting weld bead appears as a “string” or a straight line.

A stringer bead in welding refers to a straight and continuous weld bead, contrasting with a weaving bead.

When surfacing, a weaving bead minimizes dilution since the weld puddle continuously contacts the previously deposited part of the bead rather than the base metal.

Difference between Stringer and weave beads

The main difference between stringer beads and weave beads in welding lies in the technique used to deposit the weld bead along the joint.

Stringer Bead

A stringer bead involves moving the welding electrode or torch in a straight line along the joint without any side-to-side motion.

It results in a continuous, straight weld bead. The stringer bead technique is commonly used for root passes and is known for its precise control and ability to achieve proper fusion and penetration.

Weave Bead

A weave bead, on the other hand, involves a side-to-side motion of the welding electrode or torch while depositing the weld bead.

The motion creates a zigzag or weaving pattern. Weave beads are often used for fill passes and cap passes.

The weaving motion helps distribute heat and filler metal more evenly, covering a wider area and providing better reinforcement. It can also help compensate for joint variations or irregularities.

Stringer Bead vs. Weave bead

| Aspect | Stringer Beads | Weave Beads |

|---|---|---|

| Motion | Straight line without side-to-side motion | Side-to-side motion in a zigzag pattern |

| Technique | Welding electrode/torch moves straight along the joint | Welding electrode/torch moves in a weaving motion |

| Purpose | Often used for root passes | Frequently used for fill and cap passes |

| Fusion and Penetration | Provides precise control and proper fusion and penetration | Distributes heat and filler metal more evenly |

| Coverage | Creates a narrow and focused weld bead | Covers a wider area |

| Reinforcement | May require multiple passes to achieve desired reinforcement | Provides better reinforcement |

| Compensation | Less effective at compensating for joint variations or irregularities | Can help compensate for joint variations or irregularities |

Advantages of using Stringer beads

Advantages of using stringer beads in welding:

- Precise control

- Proper fusion

- Deep penetration

- Reduced distortion

- Improved visual appearance

- Time efficiency

Disadvantages of using Stringer beads

Disadvantages of using stringer beads in welding:

- Limited coverage: Stringer beads create a narrow weld bead, which may result in limited coverage, especially when welding wider joints or larger areas.

- Inadequate reinforcement: The straight line motion of stringer beads may not provide sufficient reinforcement, particularly in situations where a wider and more spread-out weld bead is desired.

- Difficulty with joint variations: Stringer beads may be less effective at compensating for joint variations or irregularities compared to weave beads, which can make it challenging to achieve consistent weld quality.

- Increased risk of undercutting: If not properly controlled, stringer beads can lead to undercutting, which is the formation of a groove or depression along the edges of the weld. This can weaken the joint and compromise its integrity.

- Limited heat dissipation: The concentrated heat input of stringer beads may increase the risk of overheating, particularly in thinner materials or when welding at higher amperages. This can potentially lead to distortion or burn-through.

- Less forgiving technique: Stringer beads require precise control and consistent travel speed. Any deviations in technique or parameter settings may result in incomplete fusion or lack of penetration.