What is Shielded Metal Arc Welding?

Shielded Metal Arc Welding (SMAW) is an early arc welding process known for its simplicity and versatility in welding various ferrous and nonferrous base metals.

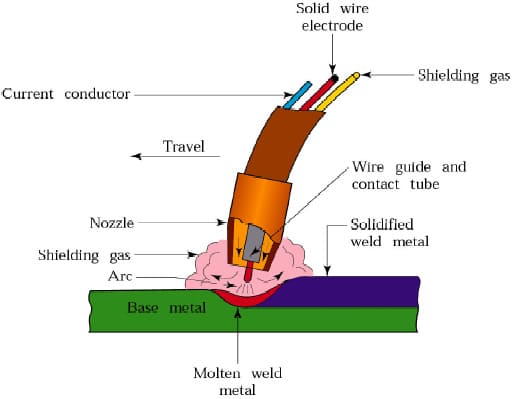

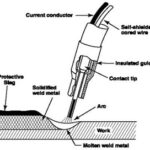

This process involves using a covered electrode composed of a core wire surrounded by a mixture of silicate binders and powdered materials. The electrode’s covering serves as a source of arc stabilizers, gases for displacing air, and protective elements for the weld metal.

Electrode Setup and Arc Initiation

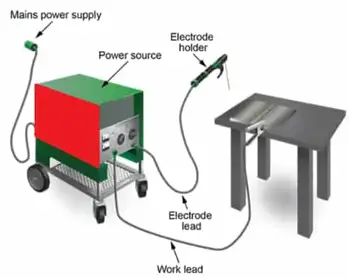

The bare section of the electrode is held in an electrode holder, which is connected to the power source through a welding lead. The workpiece is connected to the other power source terminal.

The arc is initiated by touching the electrode tip against the work and then slightly withdrawing it. The heat generated by the arc melts the base metal, the electrode’s metal core, and the covering. These molten materials combine to form the weld.

Variety of Electrodes

Covered electrodes are available in various diameters, typically ranging from 1/16 to 5/16 inches (2 to 8 mm).

Smaller diameters are suitable for joining thin sections and welding in all positions with low currents, while larger diameters are designed for high current applications, allowing for greater deposition rates in flat and horizontal positions.

The use of metal powders in the electrode coating facilitates the formulation of special alloy filler metal compositions.

Advantages and Applications

- SMAW is a preferred choice for many welding applications due to its numerous advantages.

- Job shops can efficiently handle a wide range of welding tasks using a relatively small variety of electrodes.

- The equipment required for SMAW is simple, lightweight, and cost-effective.

- SMAW enables welding in confined spaces or remote locations with limited power supply access.

- The process finds extensive application in industries such as construction, pipelines, and maintenance.

- Portable equipment is commonly used for SMAW in field work, enhancing its versatility and practicality.