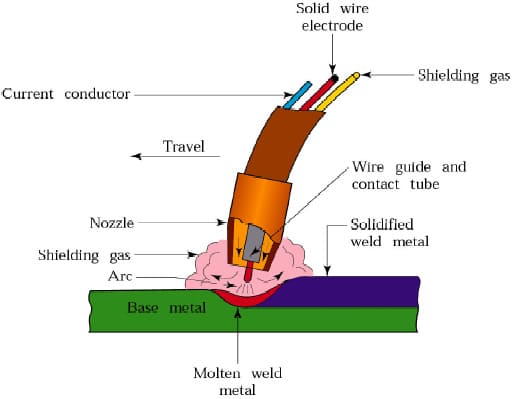

Metal transfer mode refers to the way molten metal is transferred from the electrode to the workpiece during MIG (Metal Inert Gas) welding.

The metal transfer mode is influenced by various factors such as welding parameters, electrode type, shielding gas, and material being welded.

Here are the common metal transfer modes in MIG welding:

- Short-Circuiting Transfer

- Globular Transfer

- Spray Transfer

- Pulsed Spray Transfer

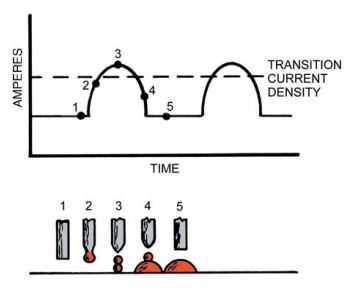

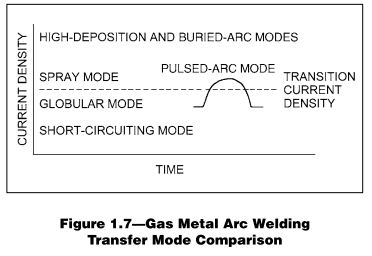

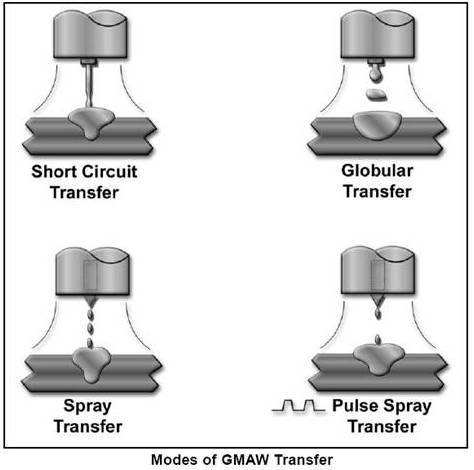

Short-Circuiting Transfer: In this mode, the welding current is relatively low, and the electrode tip briefly touches the workpiece, causing a short circuit. The short circuit creates a momentary high heat, melting the electrode wire and forming a small droplet.

The droplet detaches from the electrode and transfers to the workpiece. This mode is suitable for thin materials and results in low heat input and minimal spatter.

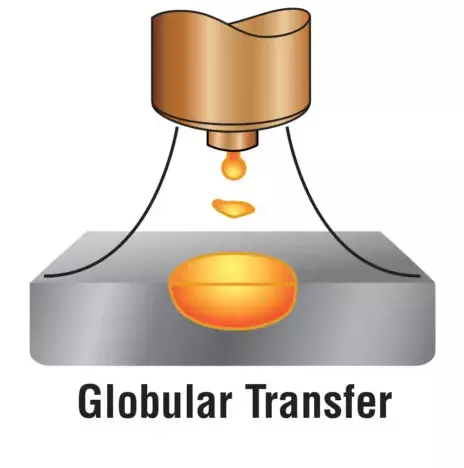

Globular Transfer: In globular transfer, the welding current is higher than in short-circuiting transfer. The electrode wire forms larger droplets that are transferred to the workpiece without short-circuiting.

The droplets are relatively larger and irregularly shaped, leading to more spatter and less control over the weld pool. Globular transfer is commonly used for thicker materials and can result in higher deposition rates.

Spray Transfer: Spray transfer is characterized by a high welding current and a stable, continuous stream of small droplets. The droplets are propelled from the electrode to the workpiece in a spray-like fashion due to the high current and the use of a suitable shielding gas.

This mode provides excellent control over the weld pool, produces high-quality welds with good penetration, and is often used for welding thick materials.

Pulsed Spray Transfer: Pulsed spray transfer combines the benefits of spray transfer and short-circuiting transfer. It involves alternating between high and low currents. During the high-current phase, small droplets are transferred in a spray-like manner, similar to spray transfer.

The low-current phase allows for cooling and solidification of the weld pool, reducing the overall heat input. Pulsed spray transfer is useful for welding thin to medium-thickness materials, providing good control and reduced distortion.