What is Short Circuit mode in MIG Welding?

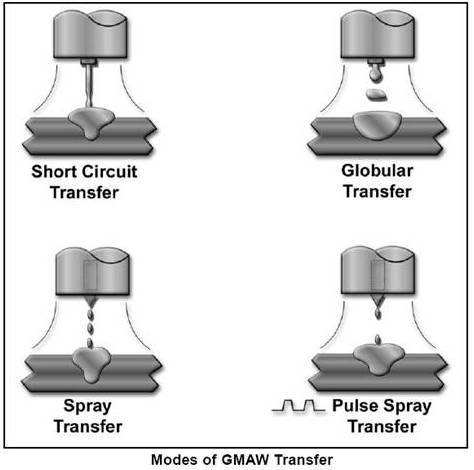

In MIG welding, the Short Circuit mode, also known as Short Circuiting Transfer mode or Short Arc mode, is one of the metal transfer modes used. It is characterized by the periodic shorting of the welding electrode to the workpiece.

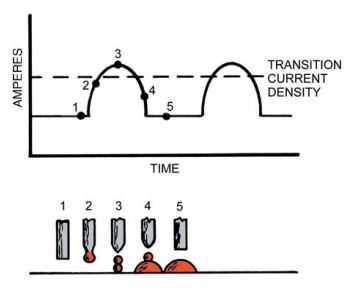

In the Short Circuit mode, a low voltage and relatively low current are employed. The welding wire is fed continuously and makes contact with the workpiece, creating an electrical circuit. As the wire touches the workpiece, the current increases, causing the wire to heat up and melt. This melting forms a small droplet at the end of the wire.

The heat generated by the arc causes the droplet to detach from the wire and transfer across the arc to the weld pool. Once the droplet transfers, the electrical current decreases, resulting in the wire making contact with the workpiece again. This process repeats in a rapid, short-circuiting manner, hence the name “Short Circuit” mode.

Welding current and voltage range for shirt circuit mode in mig welding

Welding Current Range: The welding current for the Short Circuit mode is relatively low compared to other metal transfer modes. It typically falls within the range of 40 to 200 amperes (A). However, please note that these values are approximate and can vary based on the specific welding setup and requirements.

Welding Voltage Range: The voltage used in the Short Circuit mode is also relatively low. It typically ranges from 12 to 24 volts (V). Again, it’s important to note that these values are approximate and can be adjusted based on factors such as material thickness and welding conditions.

The Short Circuit mode is commonly used for welding thin materials and in applications that require precise control over the welding process. It produces a relatively low heat input, which helps minimize distortion and burn-through on thin materials. However, it typically has a lower deposition rate compared to other metal transfer modes, such as the Spray Transfer mode.

To optimize the Short Circuit mode, welding parameters such as voltage, current, and wire feed speed need to be adjusted according to the specific welding application, material thickness, and joint configuration. Additionally, the selection of the appropriate shielding gas is essential to ensure proper arc stability and weld quality.