What is Gas Tungsten Arc Welding?

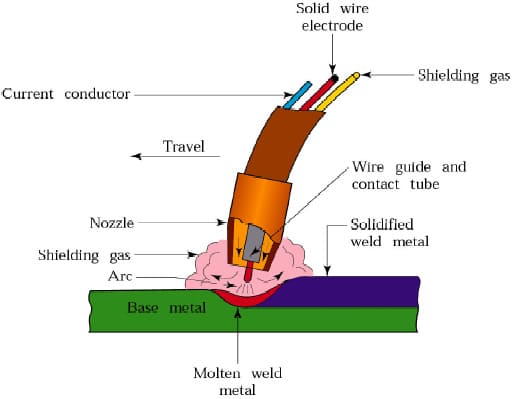

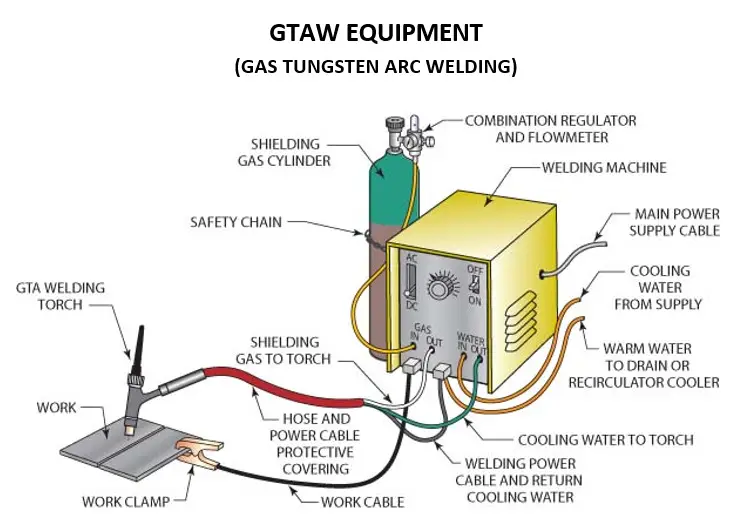

Gas Tungsten Arc Welding (GTAW), commonly known as TIG welding, employs a non-consumable tungsten electrode to sustain an arc while shielding it from the atmosphere using externally added gas.

GTAW is a highly versatile welding process that allows for the welding of thin materials and can be used with or without filler metal. It is applicable to a wide range of ferrous and nonferrous alloys and can be used in all welding positions.

Automation and Weld Control

GTAW can be utilized in automated and robotic applications. The welder has excellent control over the process, as they can establish a molten pool and add filler metal as needed.

This control ensures exceptional fusion and wetting at the beginning of the weld, minimizing the risk of incomplete fusion commonly encountered with consumable electrode processes.

Shielding Gas

In GTAW, the shielding gas is typically inert and does not participate in chemical reactions. Argon is the most commonly used shielding gas, though helium and argon-helium mixtures can be used to achieve greater weld penetration.

The inert gas displaces the ambient atmosphere, creating a nonreactive environment for welding. Reactive gases like hydrogen or nitrogen may be mixed with the inert gas to obtain specific desired effects.

However, the choice of shielding gases is limited due to potential unfavorable reactions with the tungsten electrode.

Tungsten Electrodes

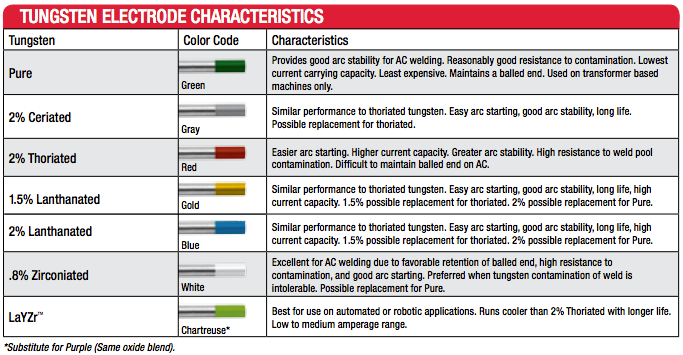

Tungsten electrodes used in GTAW are often alloyed with small amounts of oxides from other elements. Commonly used tungsten electrodes contain thorium oxide (thoria) or other oxides like cerium, lanthanum, and zirconium.

These oxides enhance electron emission and increase the electrode’s current-carrying capacity without inducing melting. The American Welding Society (AWS) provides specifications for tungsten electrodes used in GTAW.

Power Source and Polarity

The selection of a power source for GTAW depends on the required welding current. Some power sources offer square-wave AC, which provides better arc performance compared to conventional sine-wave AC.

Pulsed-arc options are also available, where a higher current pulse achieves thorough fusion, followed by a lower current pulse to prevent electrode overheating.

Polarity is important, with DCEN (electrode negative) being commonly used. DCEP (electrode positive) is rarely used, despite its effectiveness in oxide cleaning on refractory oxide surfaces of metals like aluminum and magnesium.

Adjustable Polarity

Certain GTAW power sources allow for polarity adjustments, enabling modifications to the alternating current. This can be done by changing the proportion of time duration or adjusting the amplitude of the current in the desired direction.

Adjusting the current in the electrode positive direction enhances oxide cleaning, but it also leads to additional heating of the tungsten electrode.