What is Gas Metal Arc Welding?

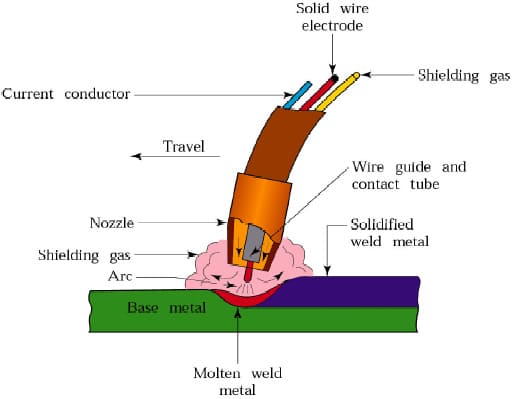

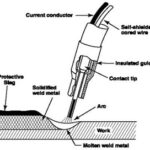

Gas Metal Arc Welding (GMAW), commonly known as MIG or wire feed welding, is a welding process that utilizes a metal arc and a consumable electrode with external shielding gas.

This versatile process allows for the welding of various ferrous and nonferrous metals, ranging from thin-gauge sections to thick plates and pipes.

GMAW can be performed in all positions, and it requires less skill compared to other welding processes like SMAW or GTAW when the variables are properly balanced.

Shielding Gas and Gas Mixture

The shielding gas used in GMAW is often a mixture that may include carbon dioxide, argon, or other gases. Some mixtures even contain small amounts of oxygen.

These gas mixtures, when properly blended, result in smoother arc performance, reduced spatter, and improved wetting of the weld to the base metal. Standardized gas mixtures are commercially available in cylinders for ease of use.

Electrode and Alloy Options

GMAW employs either a solid electrode wire or an electrode with a powdered metal core. A wide range of ferrous and nonferrous alloys are available for different applications.

Electrode sizes vary from 0.020 in. to 0.125 in., and spool weights can range from 1 lb to 60 lb, with larger coils and drums also available.

The unit cost of the electrode wire varies based on size and weight, making it economically advisable to use the largest practical size for the specific application.

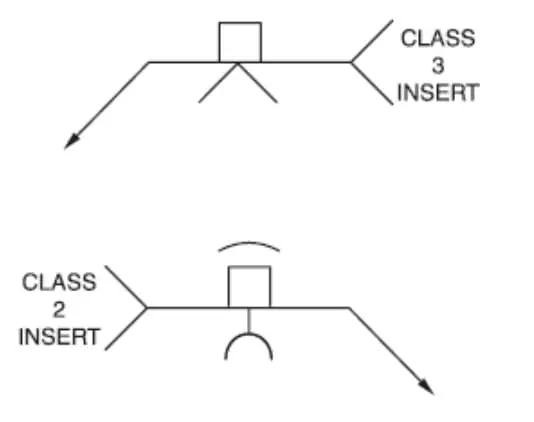

Electrode Extension and Current

The distance the electrode protrudes past the contact tip to the work, known as electrode extension, is a significant variable in wire-fed arc processes.

A slight increase in electrode extension can cause a rapid decrease in current due to increased electrical resistance. Current is directly related to wire feed speed but inversely related to extension.

Deposition rate, however, is only affected by wire feed speed. Therefore, with a constant wire feed, the deposition rate remains constant even as the current changes with extension.

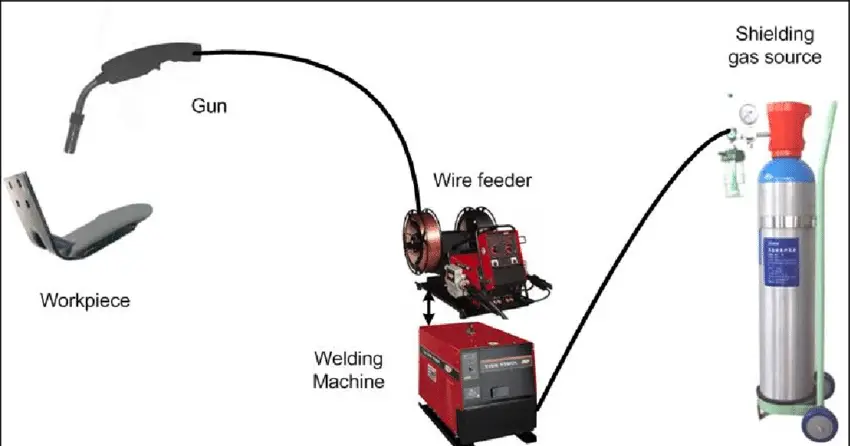

Equipment and Applications

The basic equipment for GMAW includes a welding gun (air or water cooled), electrode, electrode feed unit, welding control, power supply, shielding gas, cables, hoses, and, in the case of water-cooled torches, a water circulation system.

GMAW is suitable for semi-mechanized, fully mechanized, automatic, and robotic welding applications. In semi-mechanized welding, the operator manually controls the welding gun, while in fully mechanized setups, the gun can be mounted on a carriage and moved along the joint at a predetermined speed.