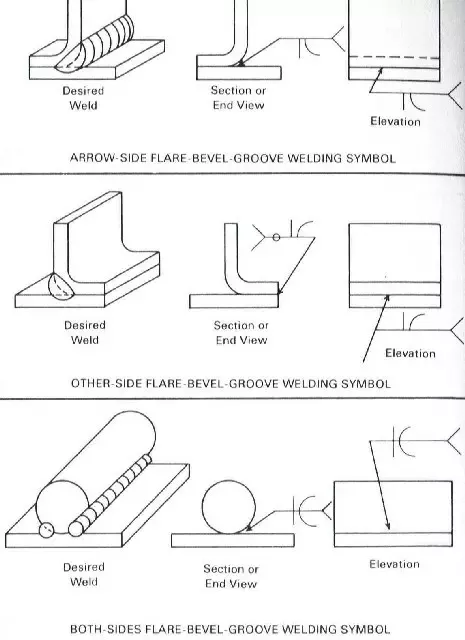

What is flare bevel weld?

A flare bevel weld is a type of weld joint used in welding applications. It is a variation of the bevel weld joint, which is commonly used to join two metal pieces with angled surfaces. In a flare bevel weld, the angle of the bevel is wider than the standard bevel weld. This wider angle creates a “flare” or outward widening of the joint.

A flare-bevel weld refers to the welding of a curved or rounded section to a flat surface. One common example is the welding of a round bar to a plate, often used as a stop in mechanical components.

Flare bevel joints can also be found in automotive panels, sheet applications, and various other applications.

Types of Flare Bevel Groove

There are several types of flare bevel groove welds that are commonly used in welding applications. Here are a few examples:

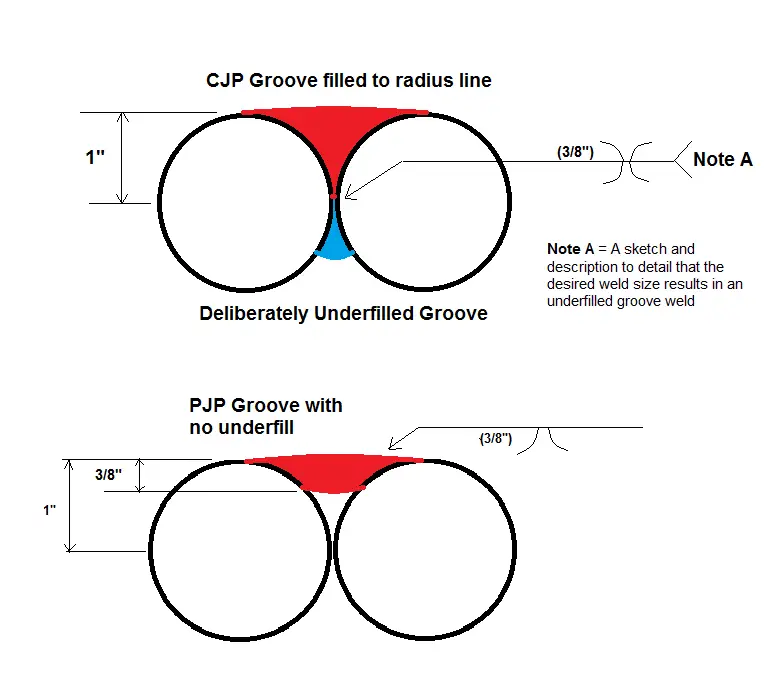

- Single Flare Bevel Groove: In this type of weld, one side of the joint has a straight bevel while the other side has a sloping flare. It is often used when joining a flat plate to a curved or rounded section.

- Double Flare Bevel Groove: This weld joint consists of two flares, one on each side of the joint. Both sides have sloping angles, creating a wider joint. It provides increased strength and improved penetration.

- Combination Flare Bevel Groove: This type of weld joint combines a flare bevel groove with another type of groove, such as a square groove or a V-groove. It is used when additional reinforcement or specific joint characteristics are required.

- Flare V-Groove: It is a combination of a flare bevel and appearance similar to a V-groove. Flare V-Groove weld has two types:

- Single Flare V-Groove

- Double Flare V-Groove