What is a fish plate weld?

A fish plate weld refers to a special type of weld used to join two sections of beams or rails end-to-end. It is commonly employed in the construction and repair of railroad tracks, as well as in other applications where a continuous and strong connection is required, such a vehicle chasis repair weld.

“The term “fish plate” originated from the shape of the metal plates used in these welds, which resemble the outline of a fish. “

Fish plates are typically made of steel and are designed to fit over the ends of two abutting plates or rails. The purpose of the fish plate is to provide alignment, stability, and strength to the joint.

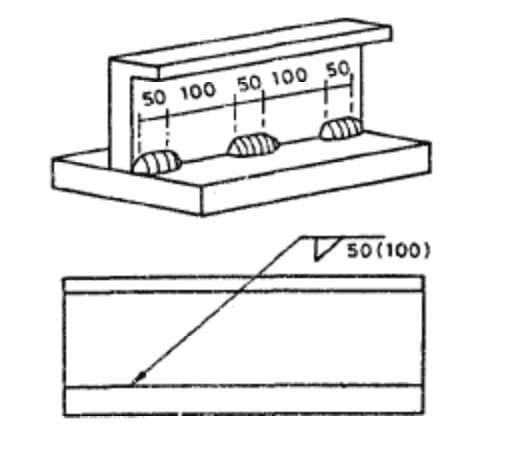

To create a fish plate weld, the ends of the plates or rails are prepared by beveling or machining to form a precise joint configuration. The fish plate is then positioned over the joint, covering the ends of the plates. Welding is performed along the edges of the fish plate to fuse it with the abutting plates or rails, creating a continuous and robust weld.

Truck frame fish plate welding

Truck frame fish plate welding refers to the welding technique used to weld repair and reinforce the connections between different sections of a truck frame using fish plates usually for welding repair purposes.

This welding technique enhances the overall strength and structural integrity of the frame. Here are some key points regarding the strength, types of loading, and welding recommendations for truck frame fish plate welding:

Strength Enhancement

- Fish plate welding provides additional strength to the joint by distributing and transferring loads more effectively across the connected sections of the truck frame.

- The weld creates a continuous and robust connection, minimizing the risk of movement or separation under various loading conditions.

- Fish plate provide additional thickness for base metal.

Types of Loading

- Truck frames are subjected to various types of loading, including:

- Static loads: The weight of the cargo, vehicle components, and occupants.

- Dynamic loads: Forces experienced during acceleration, braking, and cornering.

- Impact loads: Resulting from road irregularities, collisions, or sudden changes in motion.

Fish Plate Welding Recommendations

- To ensure a strong and durable fish plate weld for truck frames, the following recommendations are often considered:

- Welding Process: Common welding processes include shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), or gas metal arc welding (GMAW) depending on the specific requirements and materials used.

- Welding Parameters: Use a filler wire matching to the base metal.

- Pre-Weld Preparation: Proper cleaning and removal of any contaminants, such as dirt, rust, or paint, are essential for achieving a sound weld.

- Joint Design: The fish plate and frame sections should be accurately aligned and fit together properly to ensure effective load transfer and weld quality.

- Welding Technique: Employing proper welding techniques, such as maintaining a consistent arc length, controlling heat input, and ensuring adequate penetration, is crucial for achieving a reliable weld.