What is a Convex Fillet Weld in Welding?

A convex fillet weld is a specific type of weld characterized by its outwardly curved or convex face.

“In welding, a convex fillet joint refers to a specific type of connection where the weld creates a curved, outwardly bulging shape between two members that are joined together at an angle, often at a 90-degree angle.“

The convex shape of the weld offers increased surface area, facilitating a more robust connection during the welding process. Moreover, this curvature aids in withstanding external forces that may act upon the joint.

Benefits of Convex Fillet Welds

There are several advantages associated with the utilization of convex fillet welds:

- Increased Joint Strength:

Compared to other types of welds, a convex fillet weld tends to impart greater strength to the joint. The outwardly curved face of the weld distributes the load more evenly, minimizing stress concentrations and improving overall joint integrity. - Enhanced Resistance to Forces:

The convex shape of the weld helps it withstand external forces better than other types of welds. By providing a curved surface, the weld can effectively resist applied forces, reducing the risk of joint failure. - Versatile Applications:

Convex fillet welds find application in various scenarios, including joining two metal pieces, attaching metal components to a third piece, and creating a seal between two metal surfaces. This versatility makes them suitable for a wide range of welding projects.

Fillet Weld Terminology

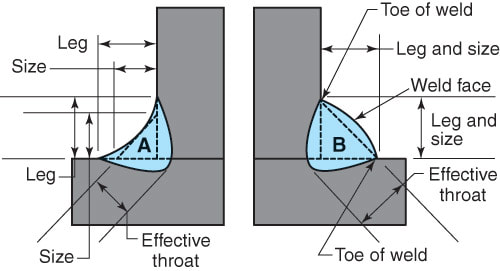

For fillet welds, the parts and measurements remain consistent across lap, inside corner, and T-joints.

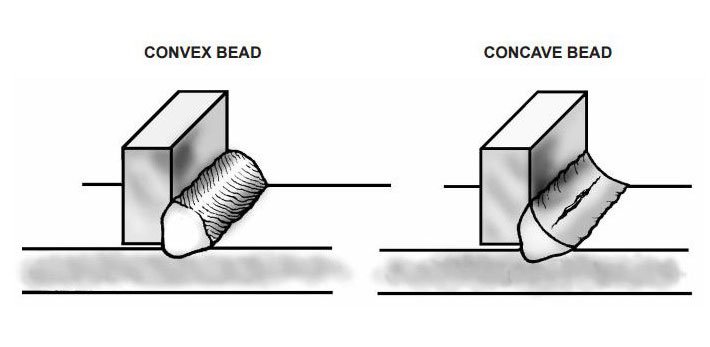

Please refer to Figure 3-8 for visual representation as given below. The outer surface of the weld bead is known as the weld face, while the point where the weld face meets the base metal surface is referred to as the weld toe.

A fillet weld consists of three key dimensions. The fillet weld size corresponds to the length of one side, while the leg represents the shortest distance from the toe to the surface of the other base metal piece. The effective throat is the minimum distance from the weld face to the weld’s root, excluding any convexity.

“Let’s examine the components of these fillet welds. Weld A has a concave shape, while Weld B is convex.

Despite both welds having the same leg sizes, the weld size in Weld B is larger. It is worth noting that Weld B features a straight or slightly convex bead.“

Figure above illustrates two fillet welds with identical leg dimensions but different sizes. In left side Figure, the weld exhibits a concave bead, resulting in a smaller size.

On the other hand, Right Figure displays a fillet weld with a convex bead, indicating a larger size. It is important to note that a fillet weld with a convex bead tends to be stronger due to the additional filler metal it contains, compared to one with a concave bead.

Design criteria of Convex Fillet Joint

To design a convex fillet joint, follow these steps:

- Identify Materials and Thickness: Determine the materials to be joined and their respective thicknesses. Consider the mechanical properties of the materials and ensure they are suitable for welding.

- Calculate Required Weld Size: Determine the necessary weld size based on the design requirements, including applied loads and desired strength. The weld size is typically specified as the leg length of the fillet weld. Use the following formula to calculate the required weld size:

- Weld Size = K * S

- Where:

- Weld Size represents the leg length of the fillet weld.

- K is a coefficient that depends on the joint configuration and type of loading. Consult welding codes or design guidelines to determine the appropriate value.

- S is the throat thickness of the fillet weld, which is related to the material thickness and the included angle of the fillet joint.

- Calculate the throat thickness using the formula:

- S denotes the throat thickness.

- T represents the material thickness.

- A is the included angle of the fillet joint.

By following this step-by-step procedure, you can ensure the design of a convex fillet joint that meets the necessary weld size, strength, and load-carrying capacity requirements.

Example Calculation

Example: Design of a Convex Fillet Joint

Given:

- Material: Stainless Steel

- Thickness: 12 mm

- Design Load: 18 kN

- Fillet Joint Angle: 45 degrees

- Joint Configuration: T-joint

Step 1: Determine Material and Thickness The material is stainless steel with a thickness of 12 mm.

Step 2: Calculate Required Weld Size Based on the design load and desired strength, let’s assume a required weld size of 10 mm (leg length of the fillet weld). The fillet joint angle is 45 degrees, so the included angle (A) is 45 degrees.

Using the formula for the throat thickness of the fillet weld:

- S = (0.707 * T) / sin(A/2) S = (0.707 * 12) / sin(45/2) S = 8.49 mm

Since the required weld size is specified as the leg length, the throat thickness (S) is equal to the weld size in this case.

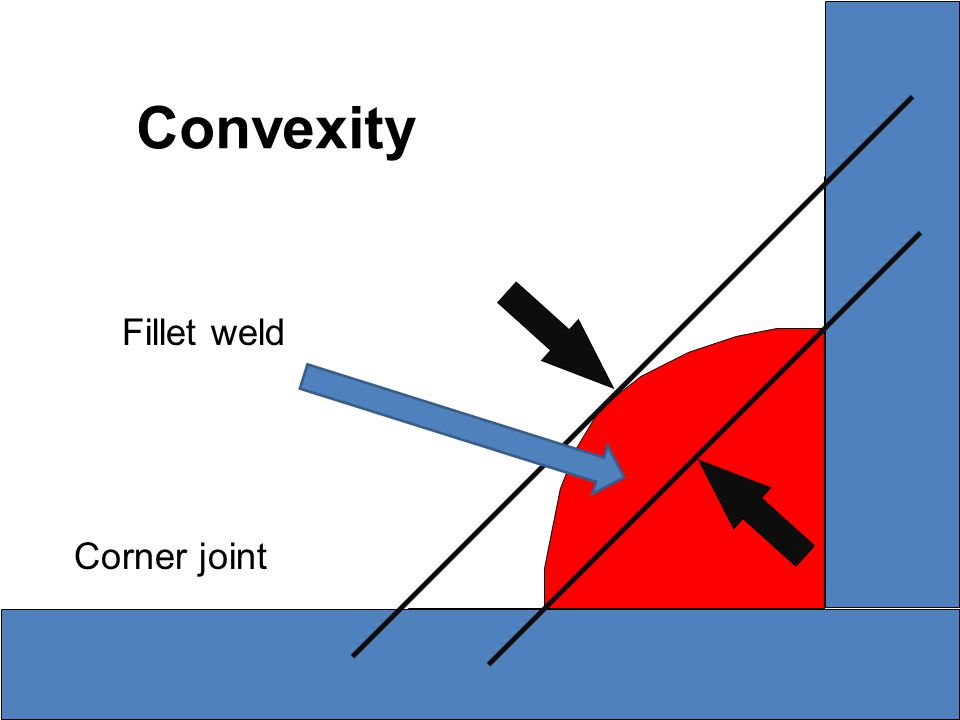

What is convexity in welding?

Convexity in welding refers to the outward curvature or bulging of a weld bead or joint. When a weld is convex, it means that the weld bead’s surface protrudes or curves outward from the base metal surface. This convex shape is typically seen on fillet welds or welds made on curved surfaces.

Convexity can occur due to various factors during the welding process, such as excessive heat input, improper welding technique, or incorrect electrode or filler metal selection. It is important to note that while a slight convexity is generally acceptable, excessive convexity can lead to potential issues.

Convexity influences the strength and integrity of the weld joint. In some cases, a convex weld can provide additional strength due to the increased volume of deposited filler metal. However, excessive convexity can result in stress concentration points, decreased joint strength, and potential defects like lack of fusion or incomplete penetration.

Welding standards and codes often specify acceptable limits for convexity to ensure the integrity of the weld. Welders and inspectors carefully monitor and control convexity during the welding process to maintain the desired weld quality and structural integrity of the joint.