What is Spray transfer mode in Welding?

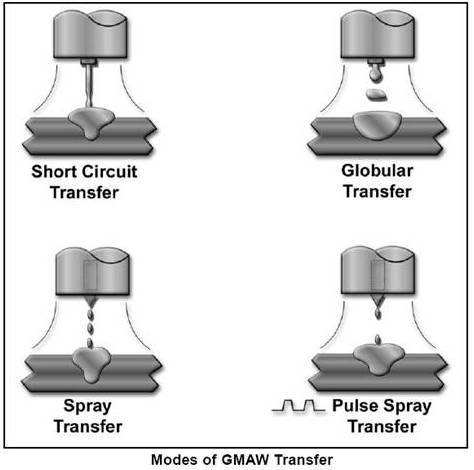

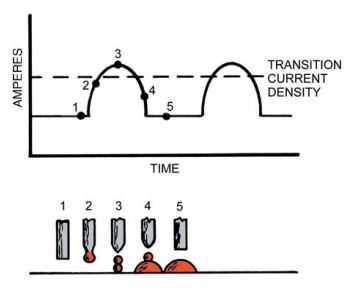

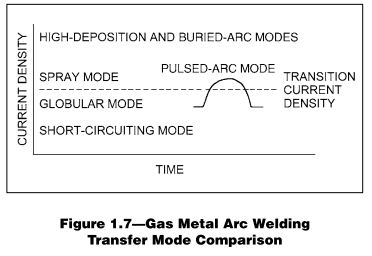

The spray transfer mode in MIG welding is activated when the current density level surpasses the transition current density level. The transition current density level is the threshold above which spray transfer occurs.

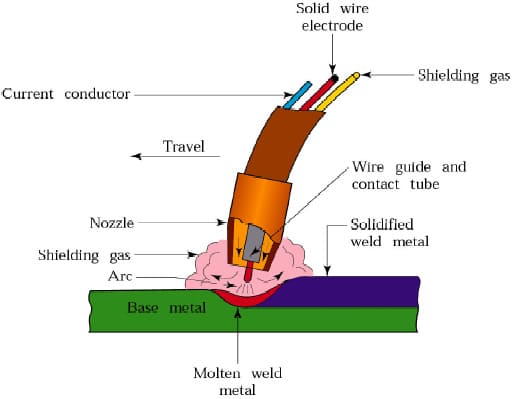

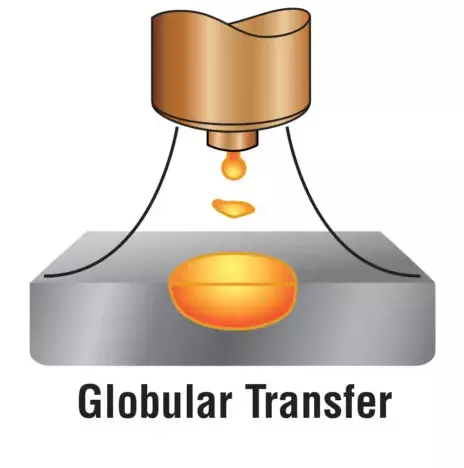

This level is represented by a dotted line in below. In the spray transfer mode, tiny droplets of electrode metal are transferred across a stable and rigid arc, as depicted in Figure below.

The arc in this mode is relatively calm and generates minimal spatter. To achieve successful spray transfer, the shielding gas mixture should primarily consist of argon.

Spray transfer mode is characterized by a significant volume of molten metal being transferred at a high rate of speed. Due to these characteristics, spray transfer is typically suitable for flat and horizontal welding positions.

The stable and forceful transfer of droplets in this mode allows for efficient welding with high deposition rates and deep penetration. However, spray transfer is less commonly used in vertical and overhead positions due to the increased risk of sagging or dripping of the molten metal.

By adjusting the welding parameters such as current, voltage, and shielding gas composition, welders can control and optimize the spray transfer mode for specific welding applications. The use of argon-rich shielding gas promotes a stable arc and minimizes spatter, resulting in high-quality welds.

Advantages of Spray transfer mode in Welding

The main advantages of the spray transfer mode in welding:

- High deposition rates: Spray transfer mode allows for a high volume of molten metal to be transferred at a rapid rate, leading to increased deposition rates. This results in faster welding and improved productivity.

- Deep penetration: The spray transfer mode provides deep penetration into the base metal, allowing for strong and robust weld joints, especially in thicker materials.

- Minimal spatter: The stable and controlled transfer of tiny droplets in spray transfer mode produces minimal spatter compared to other transfer modes. This reduces the need for post-weld cleanup and improves the overall weld quality.

- Good control and weld quality: The spray transfer mode offers excellent control over the weld pool, allowing welders to produce precise and consistent welds. The stable arc and controlled metal transfer result in high-quality welds with good fusion and minimal defects.

- Suitable for flat and horizontal positions: Spray transfer mode is particularly well-suited for welding in flat and horizontal positions. The high-speed transfer of molten metal and the stability of the arc make it easier to maintain proper weld bead shape and control.

- High efficiency: The combination of high deposition rates, deep penetration, and good control makes spray transfer mode highly efficient for welding operations. It enables welders to complete projects quickly and effectively.