This blog post covers PJP weld symbol, its interpretation, PJP Weld symbol elements with examples as well as What is a PJP Weld?

What is a PJP Weld?

A PJP weld stands for a Partial Joint Penetration weld. It is a type of welding technique used to join two metal pieces together. In a PJP weld, the weld bead does not penetrate the full thickness of the joint, but only partially.

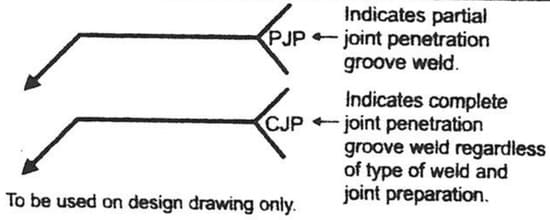

Below two examples covers what is a CJP Weld- Complete joint penetration (First one) and PJP Weld-Partial penetration weld (2nd one) along with welding symbol.

This means that the weld does not extend all the way through the joint, leaving a small gap between the weld and the base metal. PJP welds are commonly used in situations where full penetration is not required, such as when joining thin materials or when welding non-critical structures.

What is a PJP Weld Symbol?

A PJP weld symbol represents a Partial Joint Penetration weld, which is a type of groove weld. It indicates that the weld joint does not penetrate the full thickness of the material being joined. Instead, it only partially penetrates the joint, leaving a gap between the weld and the base metal.

When utilizing a CJP groove weld or a PJP groove weld, it is recommended for the designer to avoid specifying the exact groove details or indicating the symbol for a particular weld type, such as a double-V-groove or square-groove.

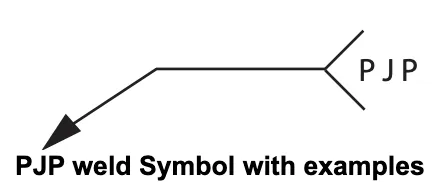

Instead, the weld arrow should be directed towards the joint location and labeled as CJP or PJP in the tail section, as depicted in above example. The specific groove details are to be determined by the Contractor/Fabricator.

Components of a PJP Weld Symbol:

- Arrow: The arrow in a PJP weld symbol points to the location where the weld is to be made. It indicates the side of the joint where the weld is applied.

- Weld Symbol: The weld symbol.

- Tail: The tail of the symbol contains PJP.

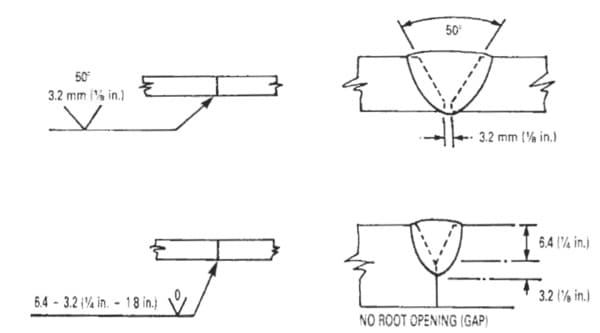

Minimum Effective Weld Size for PJP Groove Welds

The minimum Effective Weld Size for PJP Groove Welds as per AWS D1.5 depends on the material thickness and as follow:

- For T < 20 mm (3/4 in.): Minimum Effective Weld Size is 6 mm (1/4 in.)

- For T > 20 mm (3/4 in.): Minimum Effective Weld Size is 8 mm (5/16 in.)

- Notes:

- Engineer may approve smaller welds based on applied stress and appropriate preheat.

- Weld size does not need to exceed the thickness of the thinner part.

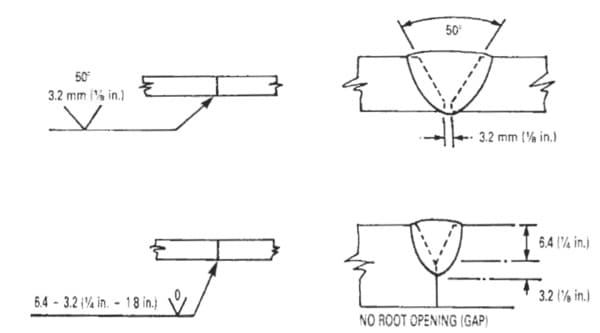

Examples of PJP Weld Symbols:

Let’s explore a few examples of PJP weld symbols to illustrate their usage:

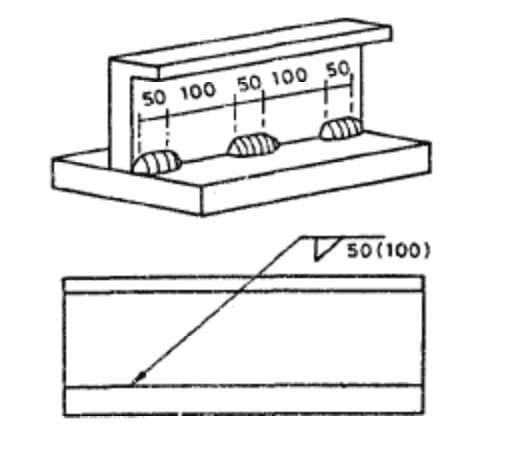

To gain a clearer understanding, let’s explore a few examples of PJP weld symbols in practical applications. For instance, in the construction of a steel bridge, the PJP weld symbol may be used to indicate the connection between the bridge deck and the supporting beams. Similarly, in the fabrication of pressure vessels, the symbol may be employed to denote the weld joint between the vessel shell and the nozzle.

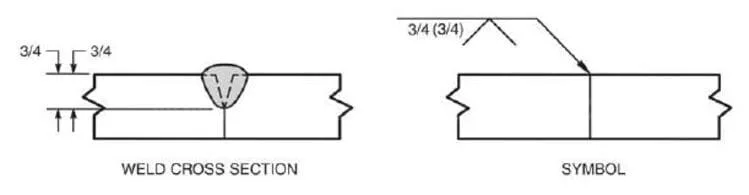

PJP Weld Symbol Example:

In this example, the PJP weld symbol represents a partial joint penetration weld on a butt joint.

Benefits and Limitations of PJP Weld Symbols

PJP weld symbols offer several advantages, including:

- Clear Communication: Weld symbols provide a standardized language for engineers, fabricators, and inspectors to communicate welding requirements accurately.

- Reduced Errors: By using PJP weld symbols, the chances of misinterpretation or confusion regarding weld joint penetration are minimized.

- Cost-Effective: PJP welds require less welding material and time compared to full penetration welds, resulting in cost savings.

However, it is important to note that PJP welds have limitations, such as reduced strength compared to full penetration welds. Therefore, their usage should be carefully considered based on the specific application and structural requirements.

Conclusion

Understanding PJP weld symbols is essential for effective communication in welding processes. By using these symbols correctly, engineers and fabricators can ensure that welding requirements are met accurately, resulting in strong and reliable joints.