What is globular transfer mode in mig welding?

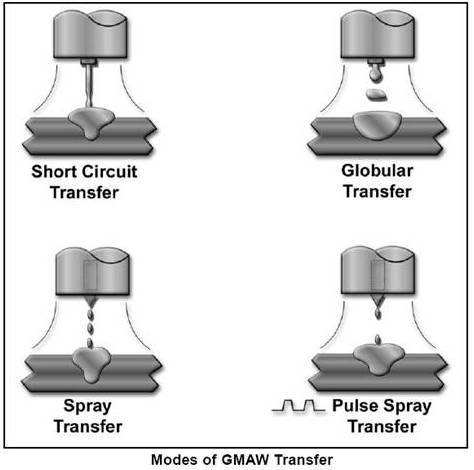

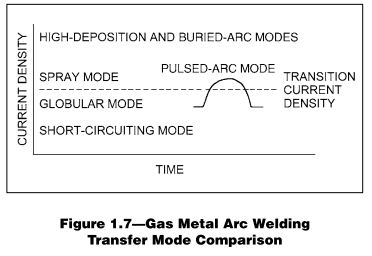

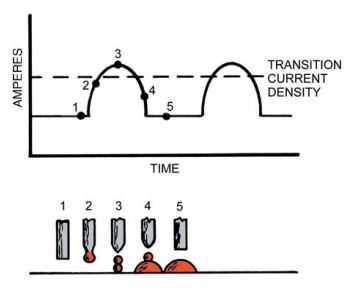

Globular transfer mode, depicted in below video, occurs when the current density is slightly below the transition current density level. When carbon dioxide is used as the shielding gas, globular transfer can happen even at high current density.

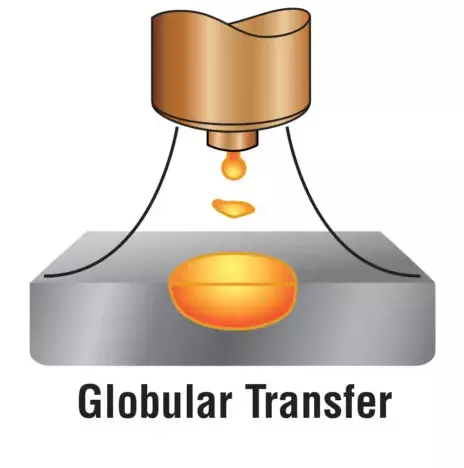

In this mode, the metal droplets formed at the end of the electrode are larger in diameter than the electrode itself.

When using a solid electrode wire, the globular mode generates an erratic arc, with metal globules being propelled from varying positions around the center of the electrode tip.

This results in significant spatter and an uneven, rough weld deposit. However, a more controlled version of this mode is employed in flux cored arc welding.

Characteristics and Behavior

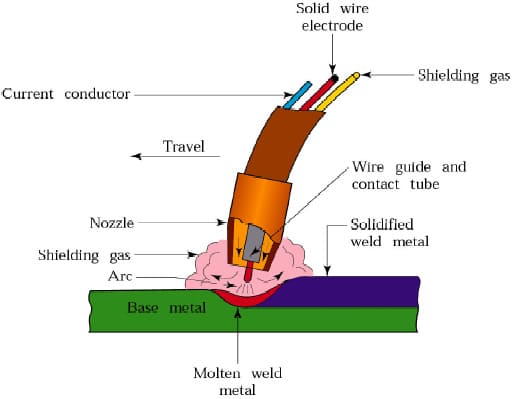

In the globular transfer mode of Gas Metal Arc Welding (GMAW), a continuous solid or metal-cored wire electrode is fed into the arc.

This wire is propelled across the arc by a combination of arc forces and gravity, resulting in the deposition of molten globules.

Figure above illustrates this transfer mode, which is characterized by large, irregularly shaped molten droplets. These droplets are larger than the diameter of the electrode and are deposited at a relatively low rate of a few drops per second.

Current and Usage

Globular transfer mode is typically employed with a lower current compared to the spray transfer mode but higher than the short circuit transfer mode.

It is often referred to as open arc welding and is performed using a non-pulsed current source. However, this mode can be challenging to control due to the high current levels, leading to significant spatter issues.

Application and Limitations

The globular transfer mode is commonly used for welding carbon steels, particularly when 100% CO2 shielding gas is utilized. It is important to note that this transfer mode is primarily suitable for flat and horizontal positions.

This limitation arises from the large size of the formed droplets, making it difficult to use in vertical and overhead positions.

Considerations for Stainless Steel Welding

When welding stainless steel using the globular transfer mode, there are additional considerations. The high content of nickel and chrome in stainless steel results in higher electrical resistance.

As a result, welding in the globular transfer mode can lead to a reduction in corrosion resistance for stainless steel welds.